FMS production simulation allocation method based on colored Petri net

A distribution method and colored technology, applied in the field of simulation, can solve the problems of complex system analysis, difficult color Petri net analysis, etc., and achieve the effect of general engineering significance, good analysis and design adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

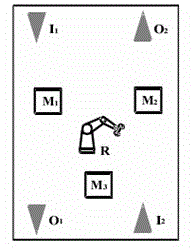

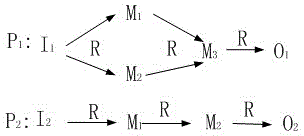

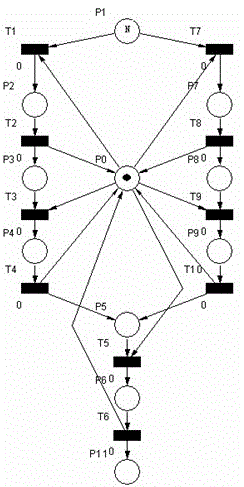

[0035] Such as Figure 1~5 The shown FMS production simulation distribution method based on colored Petri nets is characterized in that it includes the following steps: first, establish a production scheduling system model, set FMS processing units, and customize a processing strategy map. Afterwards, according to the FMS processing strategy, the elements that make up the control unit are set as places, and the Petri net system model is established. During this period, if the processing strategy diagram includes more than 2 routes, after the first Petri net system model is established, the FMS processing unit is analyzed again, and the second Petri net system model is established. By analogy, all processing strategy maps are completed to prepare for subsequent integration. Moreover, in order to effectively utilize various resources in the processing strategy, if there is a shared resource, set at least one shared resource storehouse to facilitate data retrieval. Then, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com