Nuclear reactor safety rod with rotating mechanism and its sealing structure

A nuclear reactor and rotating mechanism technology, applied in the field of ship nuclear power, can solve the problems of easy unilateral wear of safety rods, short service life, easy wear of seals, etc., and achieve the effects of increasing rigidity, improving safety, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

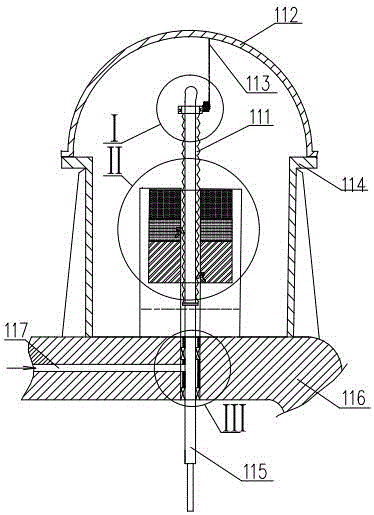

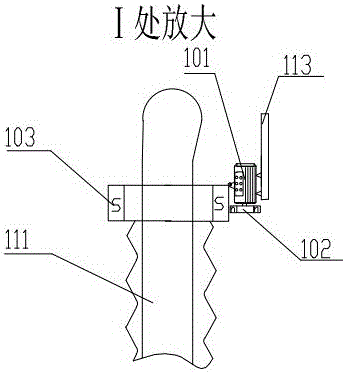

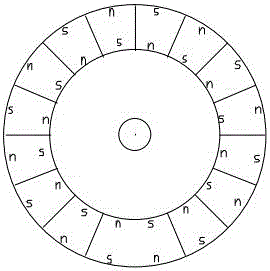

[0031] The invention specifically relates to a nuclear reactor safety rod with a rotating mechanism and its sealing structure, which is mainly used in ships and submarines with nuclear reactors, and its structure is as attached figure 1As shown, it includes a closed stroke chamber mainly composed of the pressure chamber head 116 of the nuclear reactor, the stroke housing 114 fixed on the outer surface of the pressure chamber head 116, and the stroke top cover 112. In the stroke chamber, there is a valve that extends into the nuclear reactor. Safety bar 115, the other end of safety bar 115 is connected with drive shaft 111 by coupling, the top of drive shaft 111 is provided with rotating mechanism, is provided with lifting control mechanism at the middle part of drive shaft 111, between safety bar 115 and nuclear reactor The joint of the pressure shell head 116 is provided with a sealing structure; the rotation mechanism controls the rotation of the transmission shaft and the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com