Unwinding tension control device of wound film capacitor

A tension control and film capacitor technology, applied in the direction of film/thick film capacitors, wire wound capacitors, wire wound capacitor machines, etc., can solve the problems of loose film surface, poor tension control effect, high cost, low cost and simple structure , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

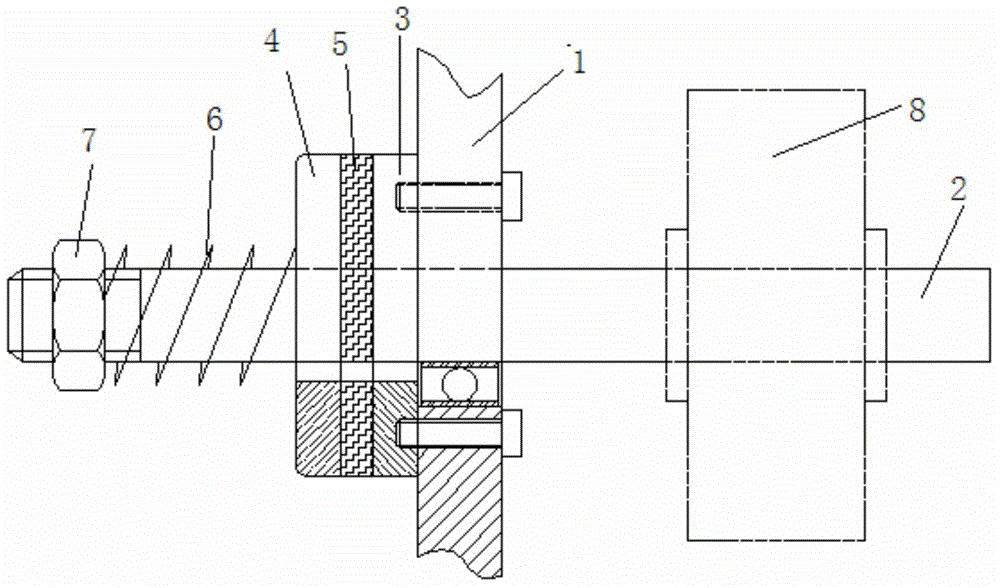

[0011] Referring to the accompanying drawings, an unwinding tension control device for winding film capacitors includes a frame 1, an unwinding shaft 2, a fixed ring 3 and a movable ring 4, the fixed ring 3 is fixed on the frame 1, and the fixed ring 3- A movable ring 4 is provided on the side, and the movable ring 4 can rotate synchronously or asynchronously with the unwinding shaft 2. A friction ring 5 is provided between the movable ring 4 and the fixed ring 3, and a spring 6 is provided on one side of the movable ring 4. The spring 6 Connect the adjusting nut 7, the adjusting nut 7 is installed on one end of the unwinding shaft 2, the unwinding shaft 2 is provided with a screw thread that matches the adjusting nut 7, and the material of the friction ring 5 is a wool felt material. When the present invention is used, the film roll 8 of the film capacitor is inserted into the unwinding shaft 2 and locked, the film on the film roll 8 is led to the core of the film capacitor to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap