Plastic throttle body

A throttle body and plastic shell technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of complex manufacturing process and heavy weight, reduce weight, reduce bottom hole process, and ensure axial channeling The effect of momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

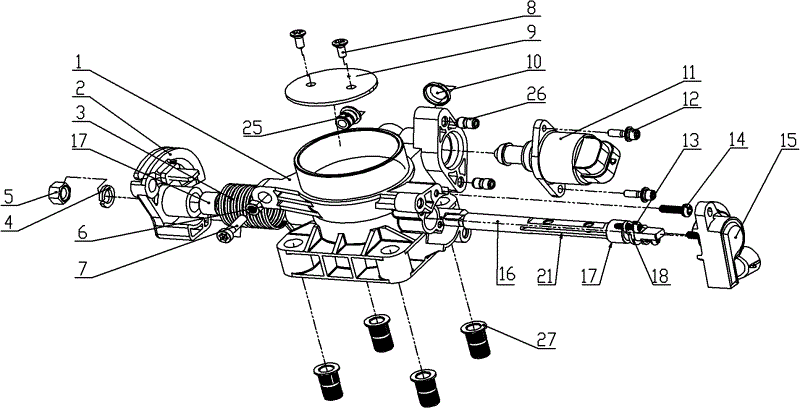

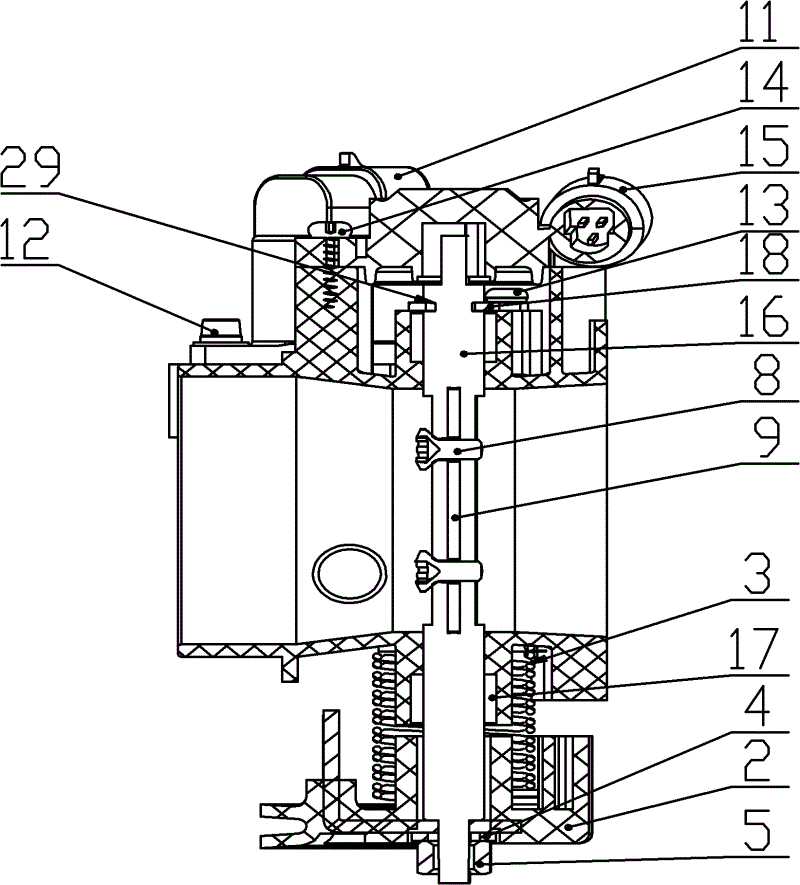

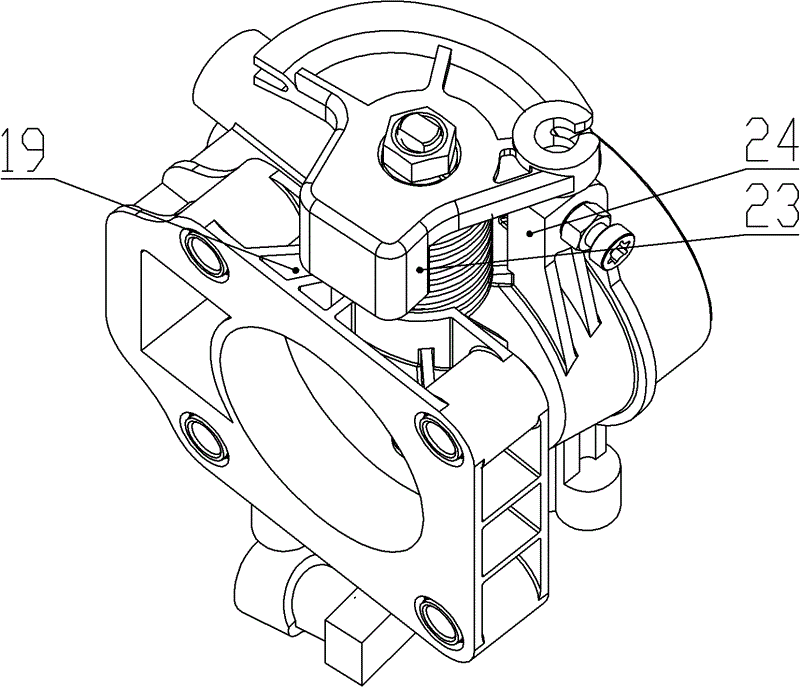

[0020] Such as Figure 1 to Figure 5 As shown, the plastic throttle body of the present invention includes a plastic shell 1, a pull wire swivel frame 2, a return spring 3, an elastic washer 4, a swivel frame fastening nut 5, an adjusting nut 6, an adjusting screw 7, and a throttle plate fastening screw 8 , throttle plate 9, cover 10, stepper motor 11, fastening screw 12, first self-tapping screw 13, second self-tapping screw 14, position sensor 15, throttle shaft 16, bearing 17 (the number is two ), limit clamp 18, first hanging pin 19, second hanging pin 20, long slot 21, first insert 25 (the number is two), second insert 26 (the number is two), mounting hole The insert 27 , the stay wire swivel insert 28 , the first insert 25 , the second insert 26 , and the mounting hole inserts 27 (there are four in nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com