Flared tube and joint tightening machine

The technology of a flared pipe and a tightening machine is applied in the field of flared pipes, and can solve the problems of manual tightening torque, tightening force and tightening angle not up to the standard, high requirements for matching the inner cone surface of the flared pipe, and large manual tightening force. Achieve the effect of reducing work intensity, avoiding occupational diseases, and speeding up tightening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

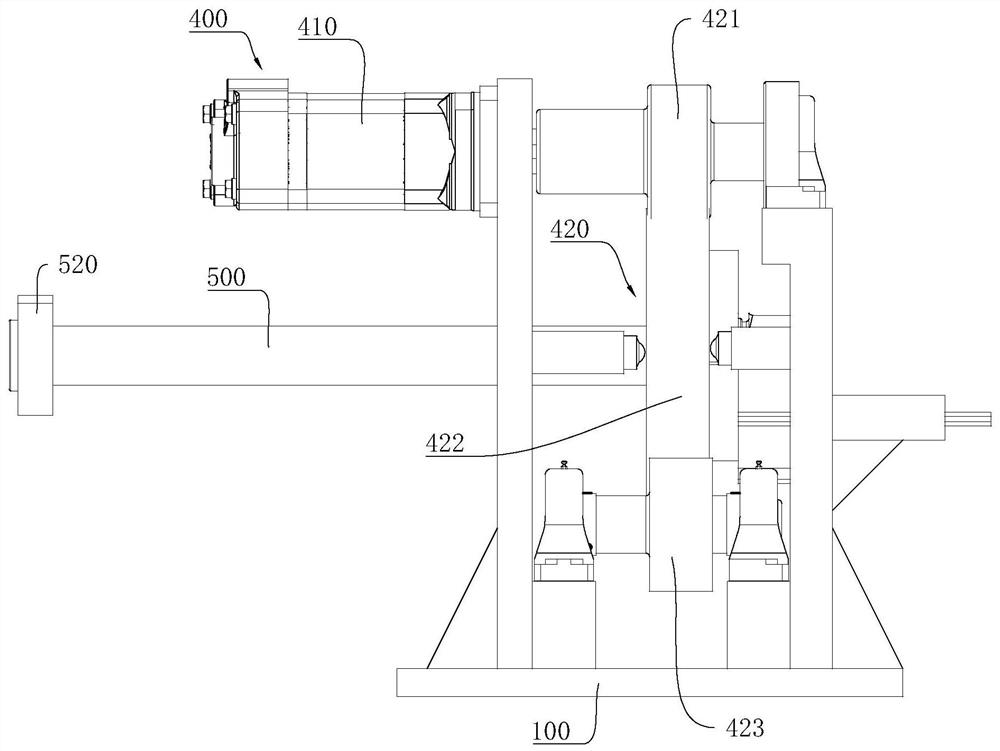

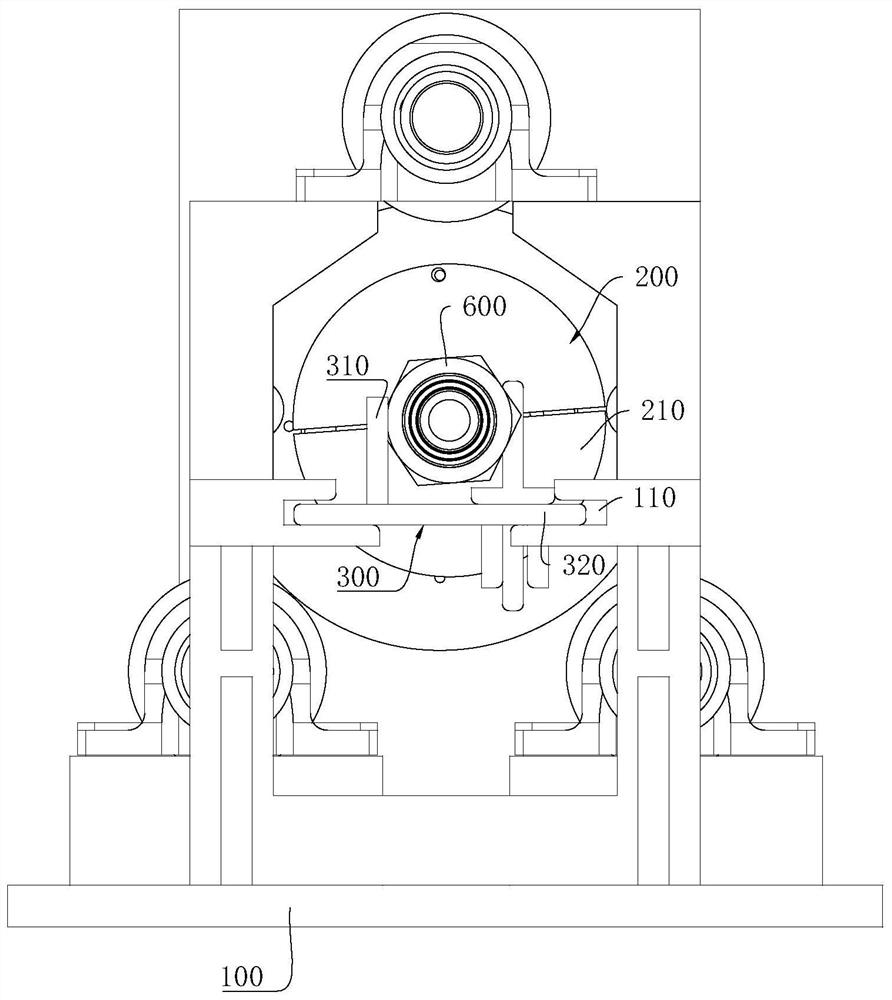

[0029] Such as Figure 1-4 As shown, a flared pipe joint tightening machine includes:

[0030] The support 100, the support 100 is used to provide support for other components.

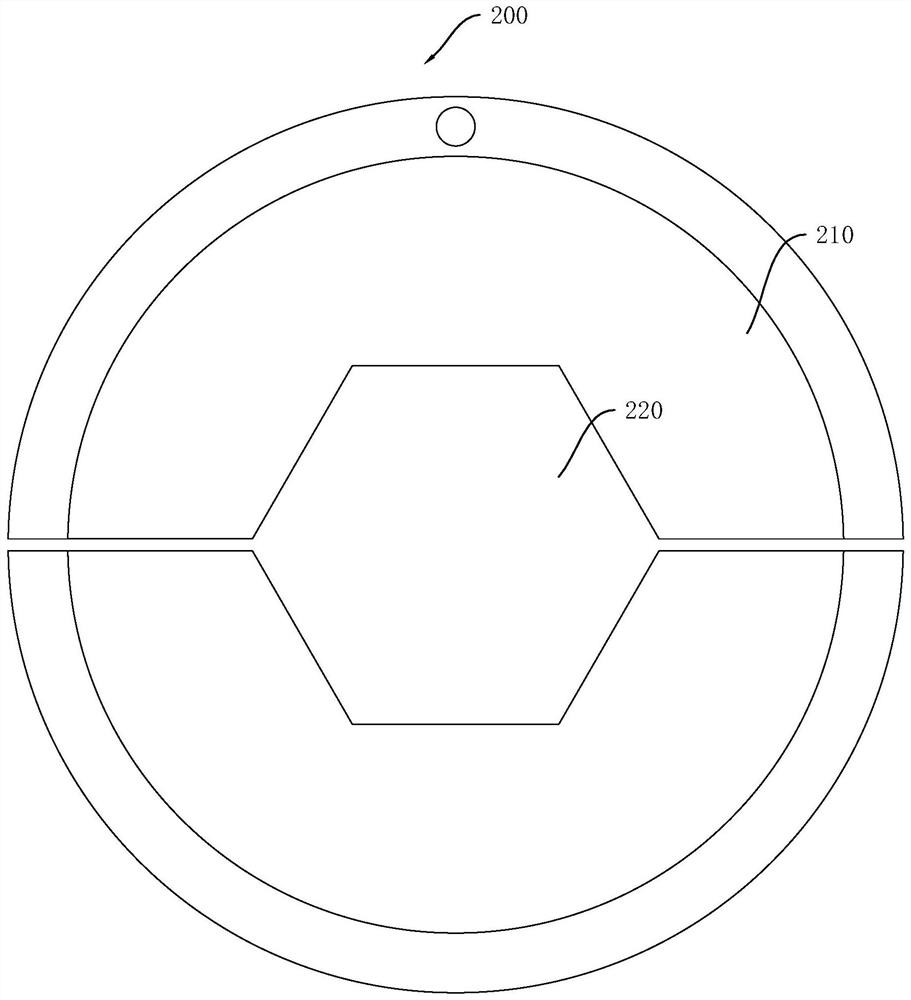

[0031] The nut clamping mechanism 200 is arranged on the support 100, and one end of the flared tube 500 is provided with a nut 510 stuck in the nut clamping mechanism 200, and the other end of the flared tube 500 is provided with a square flange 520, and the nut clamps The tightening mechanism 200 is used to clamp the nut 510 and drive the nut 510 to rotate.

[0032] The joint clamping mechanism 300 is slidably arranged on the support 100 and is used to fix the joint 600. When the joint clamping mechanism 300 slides to a preset position, the joint 600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com