Liquid-based friction generator, power generation method and sensor

A friction generator and liquid technology, which is applied in the fields of sensors, friction generators and power generation, can solve problems such as inability to utilize mechanical energy, achieve the effects of improving output performance, reducing costs, and simplifying preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

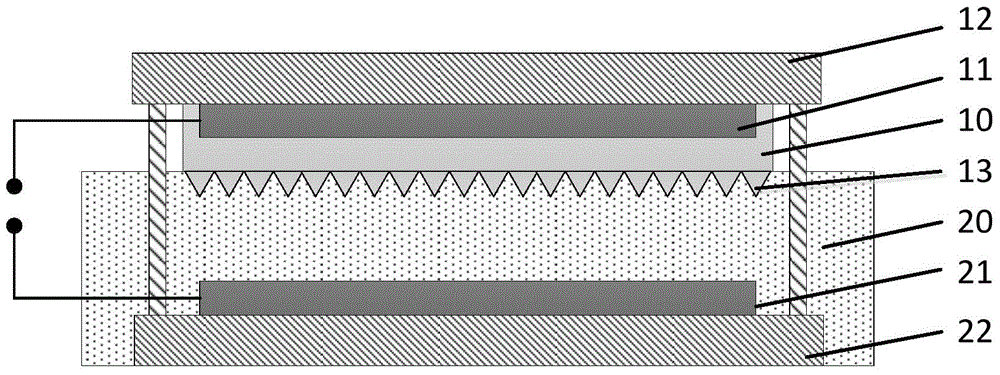

[0145] 1. River water and sea water wave energy collector

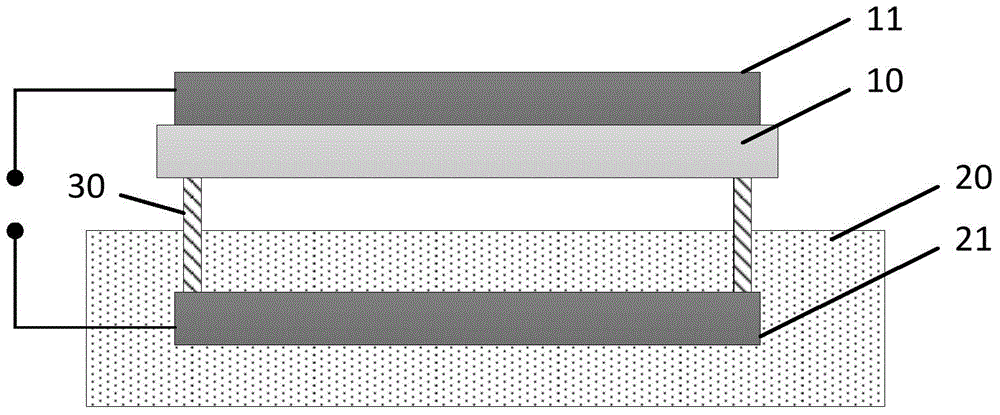

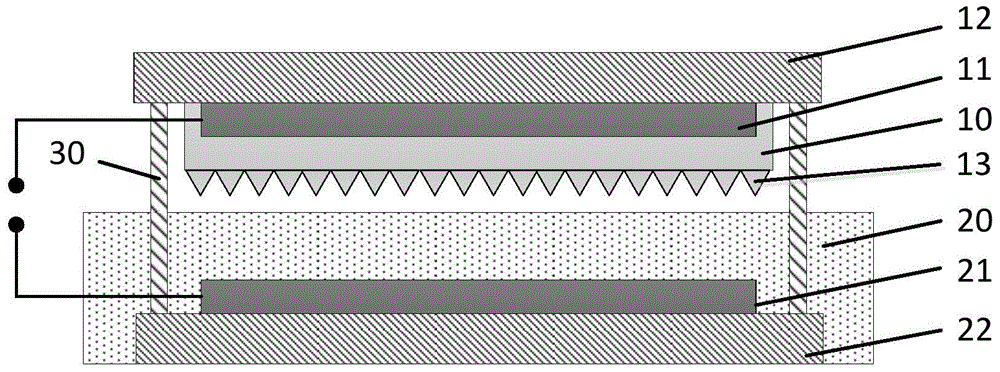

[0146] Using porous alumina with a length and width of 15cm as a template, pour into the polydimethylsiloxane mixture, bake at 120°C for 1 hour, and then remove it to get a columnar array on the lower surface (Micro-nano contact layer) Polydimethylsiloxane film (friction layer).

[0147] Take two plexiglass plates (the first substrate and the second substrate) with a length and width of 20 cm and a thickness of 0.05 cm, and plate them on the surface with an aluminum film of 15 cm in length and width and a thickness of 150 nm. It will be regarded as the first substrate and the first conductive element, and the other as the second substrate and the second conductive element.

[0148] Next, the upper surface of the polydimethylsiloxane film with the columnar array on the surface facing the first conductive element is laid flat on the first conductive element covered with the polydimethylsiloxane mixture, and the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com