System and method for detecting photovoltaic hot spot damage solar cell leak currents

A solar cell and detection method technology, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve problems such as breakdown of solar cells, permanent failure of photovoltaic modules, and small output current of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

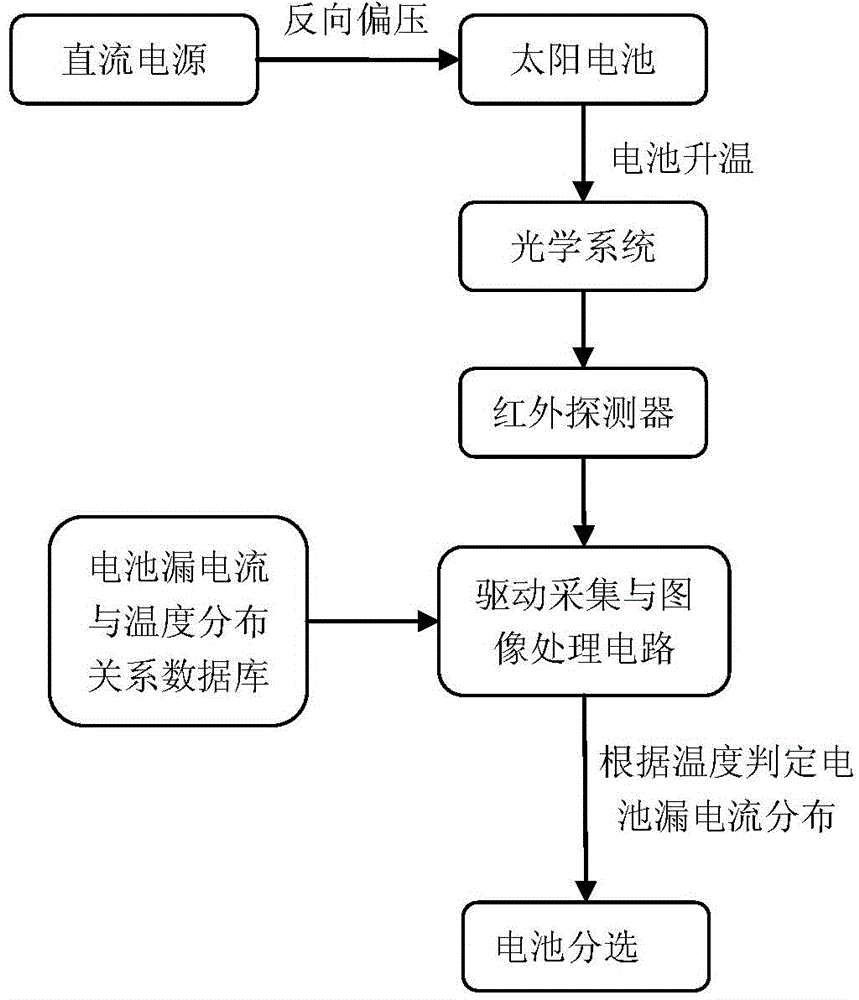

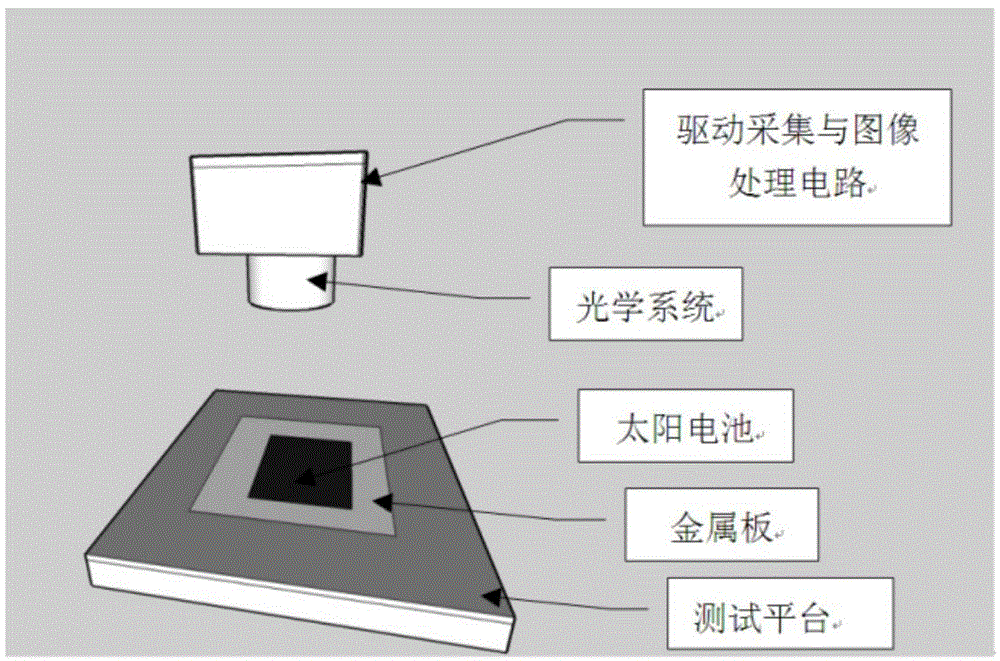

[0040] The system of the present invention for detecting the leakage current of solar cells damaged by photovoltaic hot spots is as follows: figure 2 As shown, including test platform, metal plate, optical system and drive acquisition and image processing circuit. On the insulating test platform, a metal plate is set. The test platform is made of insulating and heat preservation materials. The metal plate has good conductivity and small heat capacity. The optical system is placed above the solar battery. The optical system and the drive acquisition and image processing circuit Connected, the optical system is composed of an infrared detector and an optical imaging objective lens. The infrared radiation energy distribution pattern of the measured target is received by the infrared detector and the optical imaging objective lens and reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com