Axial flow exhaust turbine

An exhaust turbine and axial flow technology, which is applied in the direction of machines/engines, engine functions, stators, etc., can solve the problems of performance degradation, cost increase, and overall size of the turbine, and achieve damage prevention, easy maintenance, and Cost suppression effect of maintenance expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

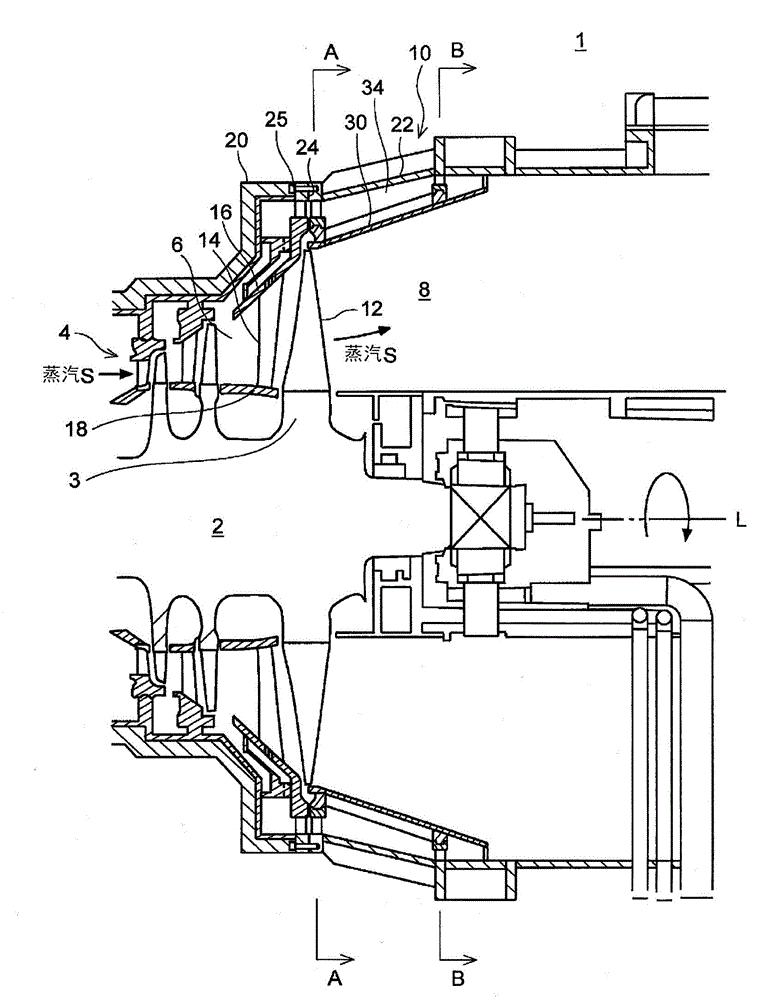

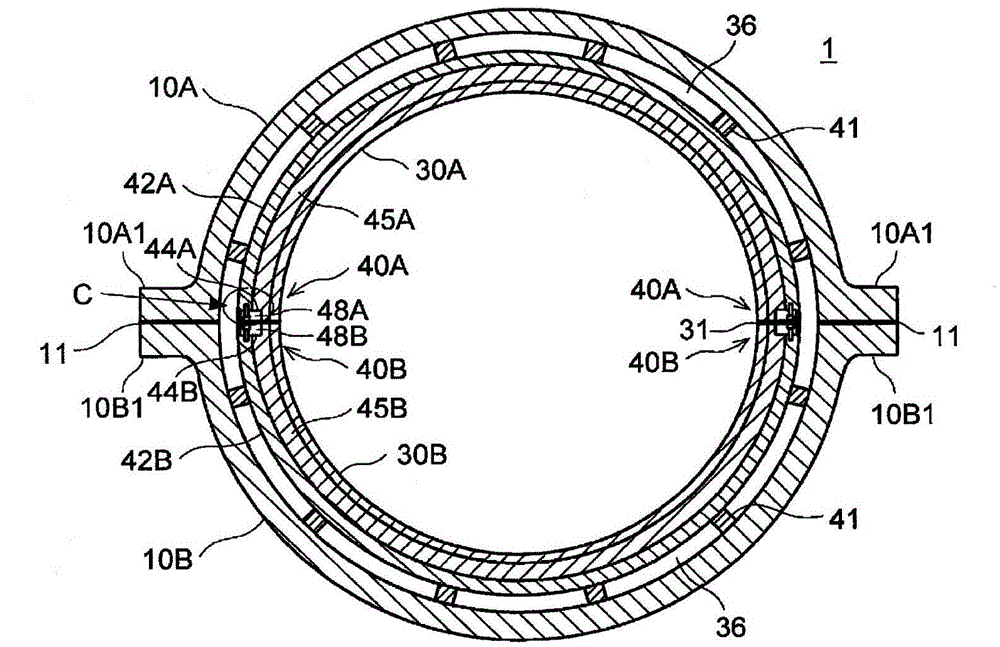

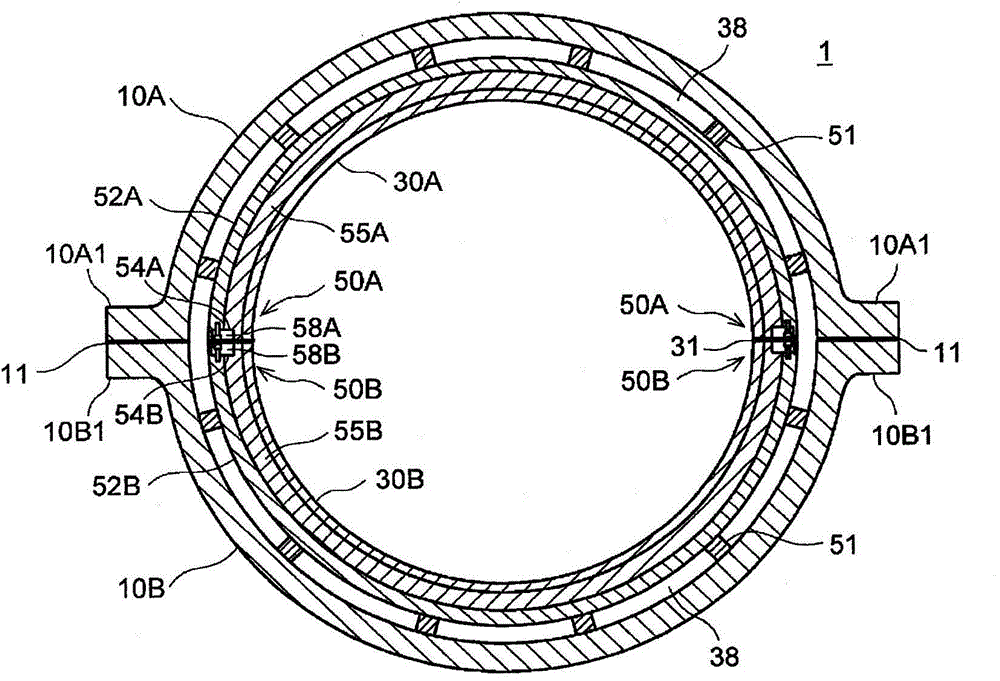

[0062] figure 1 is a cross-sectional view showing the overall configuration of the axial flow exhaust turbine according to the first embodiment, figure 2 yes figure 1 The A-A line sectional view of the axial flow exhaust turbine shown, image 3 yes figure 1 The B-B line sectional view of the axial flow exhaust turbine shown, Figure 4 It is a sectional view of main parts showing the periphery of the inner partition wall of the axial flow exhaust turbine. It should be noted, Figure 4 shown with figure 1 Figures of the same section (vertical section).

[0063] Such as figure 1 As shown, the axial flow exhaust turbine 1 has: a rotor 2, an airfoil 4 arranged around the rotor 2, a steam passage 6 passing through the airfoil 4, an exhaust chamber 8 provided on the downstream side of the steam passage 6, and an internal A vehicle interior 10 with a steam passage 6 and an exhaust chamber 8 .

[0064] The rotor 2 is supported rotatably with respect to the cabin 10 . A plura...

no. 2 approach 〕

[0093] Next, an axial flow exhaust turbine provided with an inner partition wall different from that of the first embodiment will be described as a second embodiment. The structure of this embodiment is the same as that of the first embodiment except that the structure of the inner partition wall is different.

[0094] Figure 8 is a sectional view showing the overall structure of the axial flow exhaust turbine according to the second embodiment, Figure 9 It is a sectional view of main parts showing the periphery of the inner partition wall of the axial flow exhaust turbine according to the present embodiment. Figure 10 yes means Figure 9 An enlarged view of part E of the positioning structure of the inner partition wall on the upstream side shown, Figure 11 yes Figure 10 Front view of line F-F shown.

[0095] It should be noted that the same names and symbols are used for the same structures, components, and the like as those of the first embodiment, and detailed de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com