Shelling projection type forest fire extinguisher

A forest fire and fire extinguisher technology, which is applied in the field of bombardment-type forest fire fire extinguishers, can solve the problems of small fire extinguishing agent filling, easy splashing of the shell, and danger to personnel, and achieve high fire extinguishing efficiency, increase the filling volume, and connect reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

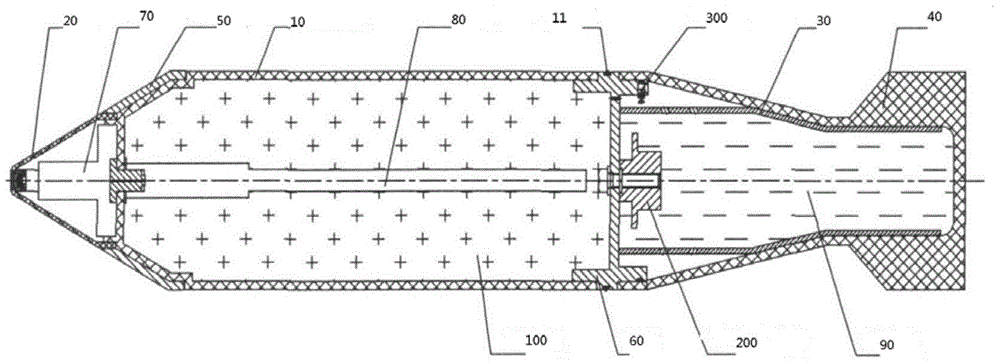

[0017] Please refer to figure 1 , figure 2 , the cannonball throwing type forest fire fire extinguisher of the present invention, it comprises cylindrical main body 10, the wind cap 20 that is arranged on the front end of cylindrical main body, the umbrella cover 30 that is arranged on cylindrical main body rear end and the empennage 40 that is arranged on umbrella cover tail.

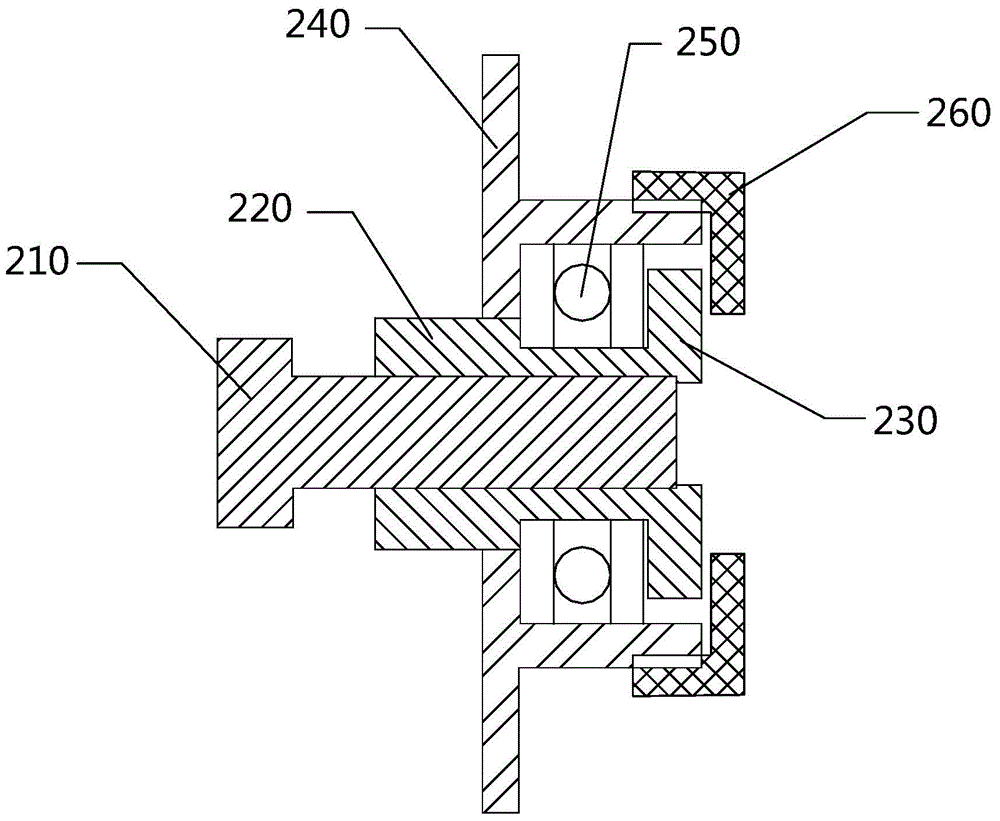

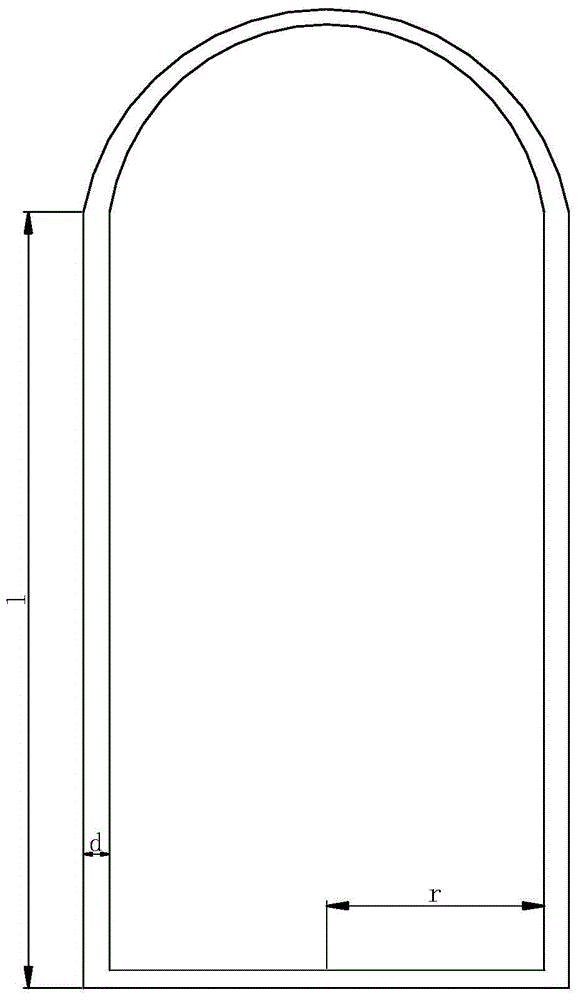

[0018] The hood 20 is separated from the cylindrical main body 10 by a pressure seat 50, and the cylindrical main body 10 is separated from the umbrella cover 30 by a bullet seat 60; The outlet portion abuts against the end of the tapered inner surface of the umbrella cover 30 , and the bottom is fixed on the bearing seat 50 .

[0019] The fire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com