Preparation method of graphene-nano zinc oxide composite photocatalytical material for adsorbing and degrading nitrosamine

A nano-zinc oxide and composite photocatalysis technology, applied in the interdisciplinary field of disciplines, can solve problems such as outstanding achievements in applied research, and achieve the effects of low cost, good adsorption performance and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Graphite expansion pretreatment: 3g of natural flake graphite was added to 12ml concentrated H at 80°C 2 SO 4 , 2.5g K 2 S 2 o 8 and 2.5g P 2 o 5 The mixed solution was kept at 80° C. for 4.5 hours, then the mixture was cooled to room temperature, diluted with 500 ml of deionized water and left for 12 hours. The mixture was washed with deionized water, filtered to remove residual acid, and dried at room temperature to obtain pretreated graphite.

[0042] Oxidation into graphite oxide (GO) by Hummer’s chemical method: pretreated natural graphite powder was added to 120ml of concentrated H at 0°C 2 SO 4 In, followed by 15g KMnO 4 Slowly added to the above mixed solution while stirring and continued to stir at below 35°C for 2 hours. Next, add 250ml of deionized water to dilute the mixture. Since the addition of a large amount of water will release a lot of heat, this step is performed in an ice-water bath to ensure that the temperature is lower than 50°C. After a...

Embodiment 2

[0049] The expansion treatment of graphite and the process of oxidation into graphite oxide are the same as in Example 1.

[0050] Weigh 0.1g of graphite oxide and disperse it into deionized water. Graphite oxide is relatively easy to disperse into water, and then the solution is ultrasonicated for 1 hour to peel the graphite oxide into graphene oxide sheets. % graphene oxide dispersion. Then take 10g of the above-mentioned uniformly dispersed graphene oxide dispersion liquid and mix it with 1g of nano-ZnO, stir and ultrasonically disperse the ZnO evenly, and then add 35wt% hydrazine hydrate and graphene oxide according to the mass ratio of hydrazine hydrate and graphene oxide in the system about 6:15. Hydrazine solution, and an appropriate amount of concentrated ammonia water and deionized water, so that the pH of the system is 9-10, and the water content is 98-99wt%. After stirring vigorously for a few minutes, place it in a water bath at 90°C for 2 hours. The reacted mixtur...

Embodiment 3

[0055] The pretreatment of graphite and the step that oxidation forms graphite oxide are with embodiment 1;

[0056] Weigh 0.1g of graphite oxide and disperse it into deionized water. Graphite oxide is relatively easy to disperse into water. Then the solution is ultrasonicated for 1 hour to peel the graphite oxide into graphene oxide sheets. % graphene oxide dispersion. Then take 100g of the uniformly dispersed graphene oxide dispersion prepared above and mix it with 10g of ZnO, stir and ultrasonicate for about half an hour to disperse the ZnO evenly, and then add 35wt% of hydrazine hydrate according to the mass ratio of hydrazine hydrate and GO in the system is about 6:12 solution, and an appropriate amount of concentrated ammonia water and deionized water, so that the pH of the system is 9-10, and the content of solvent water is 98-99 wt%. Dry it in a vacuum oven for 12 hours.

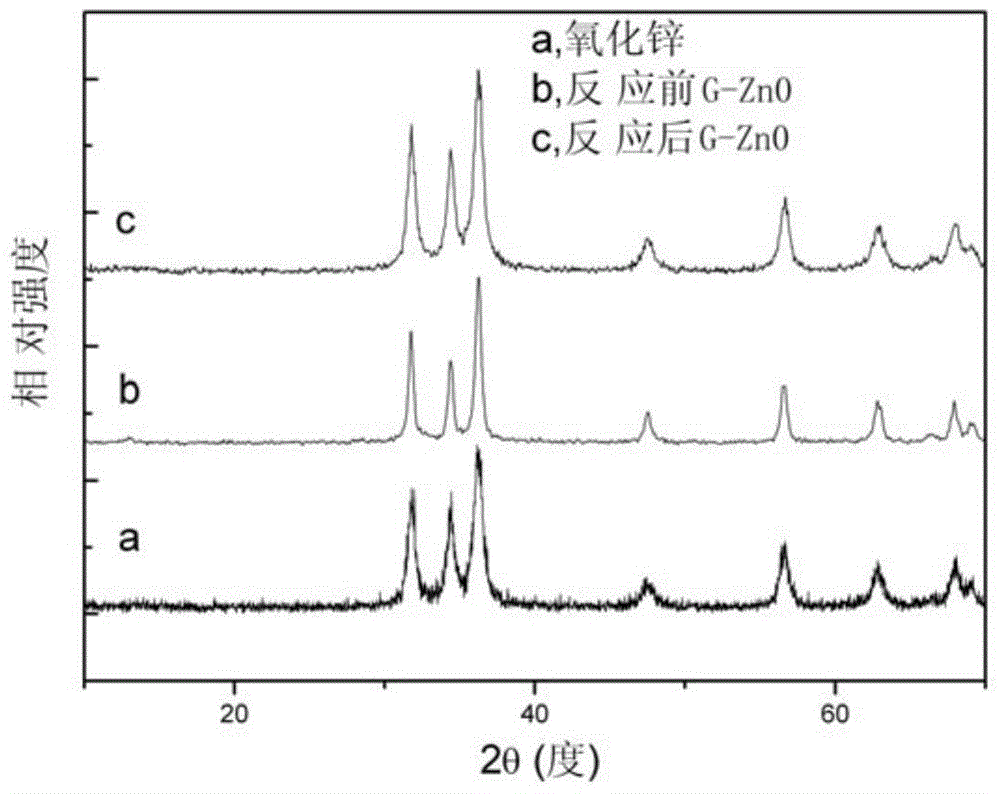

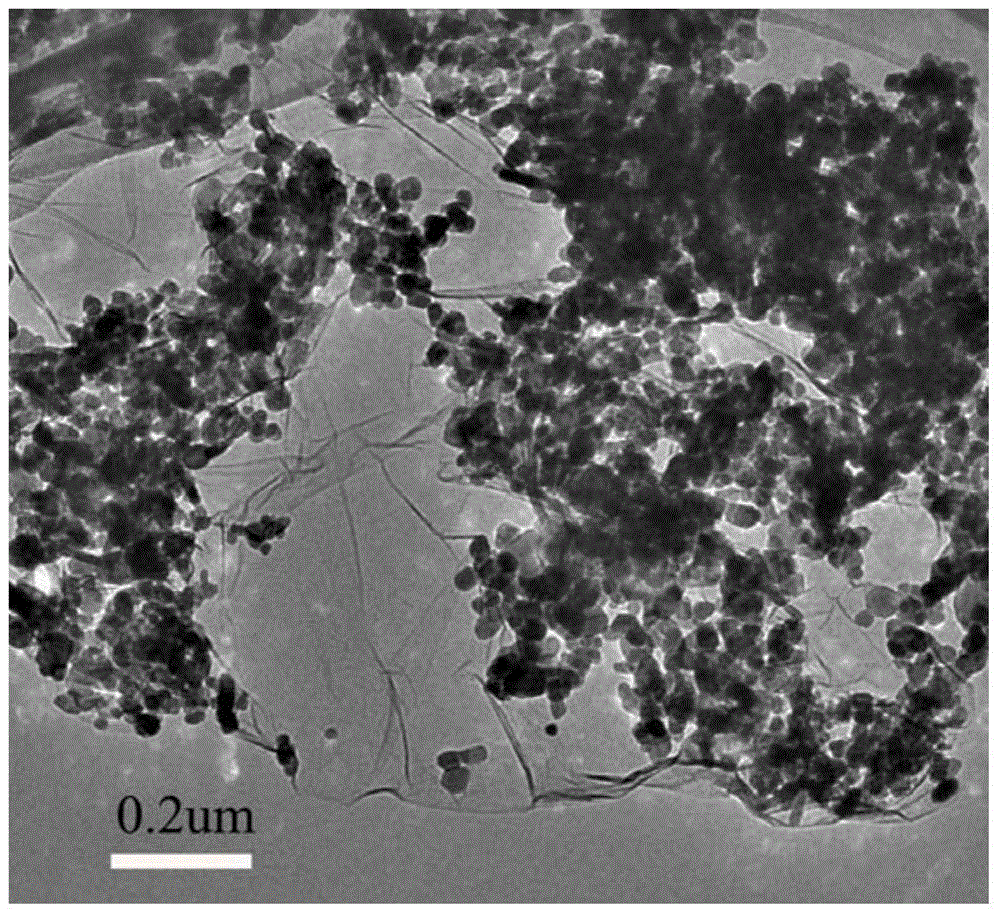

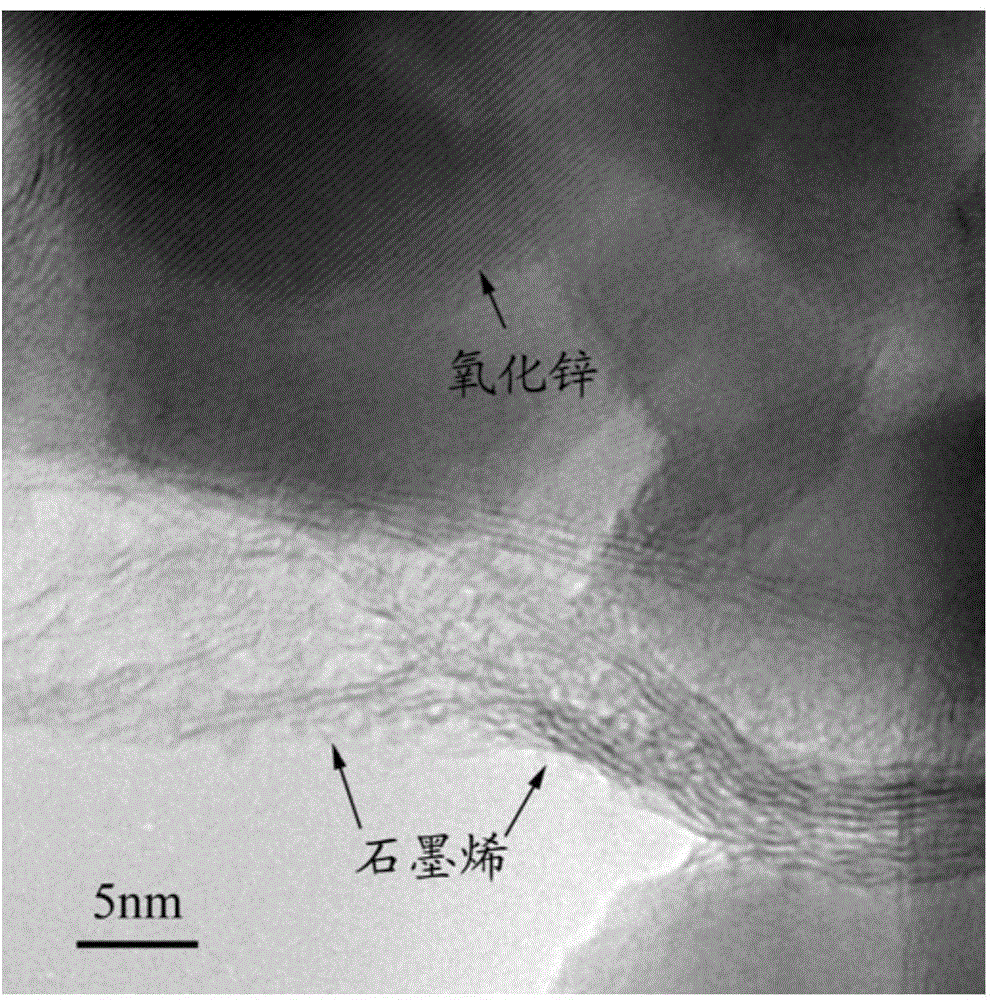

[0057] The electron microscope pictures of the obtained G-ZnO nanocomposites are similar to f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap