Tool special for stay manufacture

A special tool and wire-pulling technology, applied in the field of tools produced on-site in power transmission lines, can solve problems such as easy detachment and injury, and achieve the effects of improving construction efficiency and operating standards, reducing strength and reducing the possibility of corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

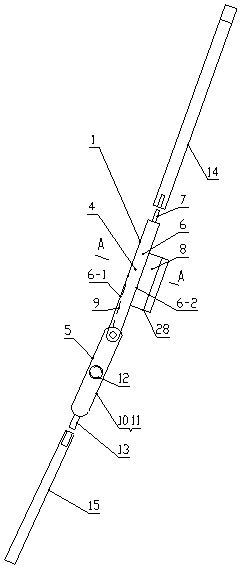

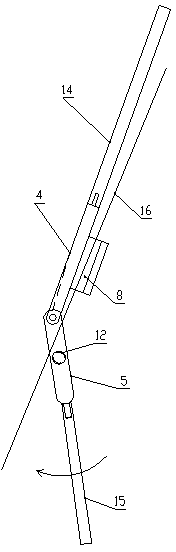

[0022] The special tool for backguy making of the present invention comprises a backguy gripper 1, a backguy clamp tightener 2 and a backguy fixer 3;

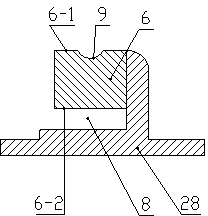

[0023] Such as figure 1 , 2 As shown, the cable gripping device 1 includes an upper gripping mechanism 4 and a lower gripping mechanism 5, the lower end of the upper gripping mechanism 4 is rotationally connected with the upper end of the lower gripping mechanism 5, and the upper gripping mechanism 4 includes an upper gripping mechanism 5. Column 6, the upper holding curved column 6 is a rectangular column, the top of the upper holding curved column 6 is fixedly connected with a vertically arranged upper connecting bolt 7, and the rear side 6-2 of the upper holding curved column 6 is fixedly connected with a bending groove 8, The bending groove 8 is made of the T-shaped plate 28 welded on one side of the bending column 6 and the rear side 6-2 of the bending column 6. The opening of the bending groove 8 faces the left side or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com