Pneumatic return lotion pump

A reset type, lotion pump technology, applied in the field of lotion pump, can solve the problems of inconvenient assembly, complex structure, polluted lotion, etc., and achieve the effect of preventing contamination of liquid and convenient assembly and coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

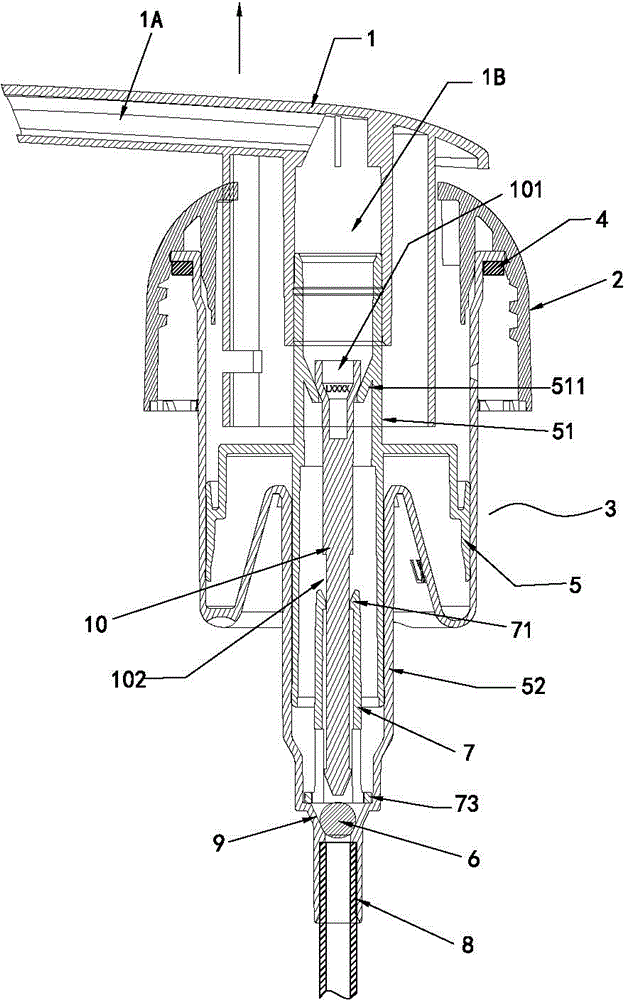

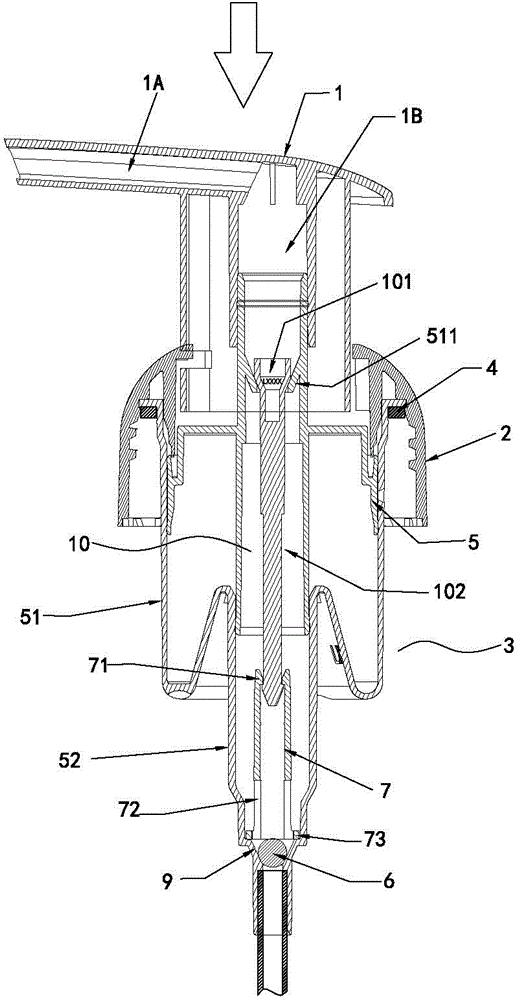

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, an air pressure reset lotion pump includes a press head 1, a thread 2, a body 3, a gasket 4, a piston 5, a ball 6 and an auxiliary column 7, and the press head 1 has a liquid outlet nozzle 1A and The catheter interface 1B, the liquid outlet nozzle 1A is connected with the catheter interface 1B; the upper end of the body 3 is connected to the thread 2, and the gasket 4 is located at the lower part of the outer edge of the upper end of the body and fits it; the lower part of the body 3 The upper end of the liquid inlet port 8 has an inverted truncated cone-shaped one-way valve seat 9, the ball 6 is arranged on the one-way valve seat 9, the lower end of the auxiliary column 7 cooperates with the ball 6, and the lower end of the auxiliary column 7 and the body 3 The bottom plate cooperates; the piston 5 and the inner cavity of the body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com