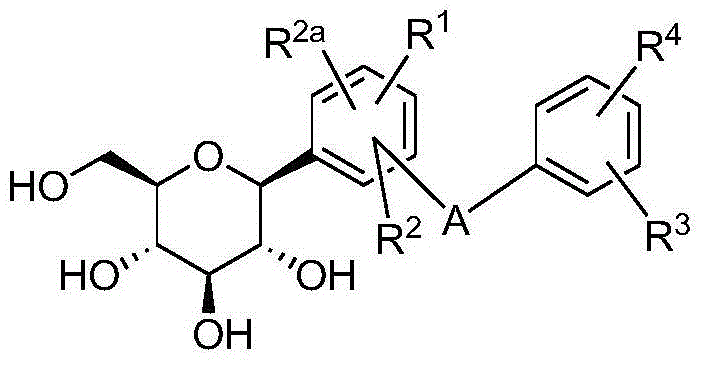

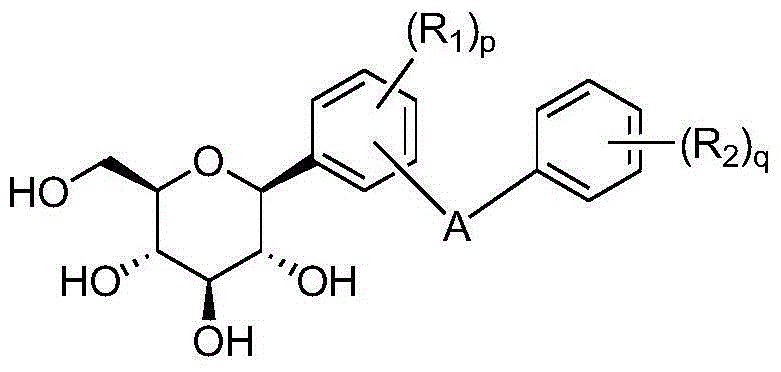

Class of alcoxyl phenyl propylene glycol derivative and preparation method and application of class of alcoxyl phenyl propylene glycol derivative

A technology of alkyl and alkyllithium, which is applied in a class of alkoxyphenylpropylene glycol derivatives, its preparation and application, and can solve problems such as side effects and difficulty in controlling blood sugar in patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

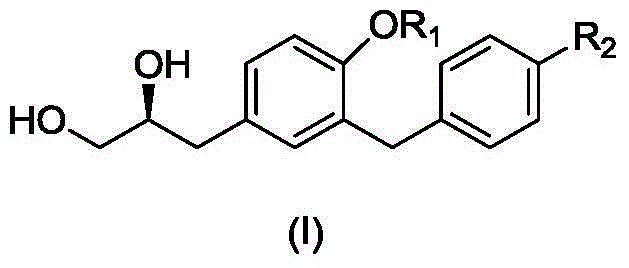

[0028] The preparation of embodiment 1 I-1

[0029]

[0030] Add 3.05g (10mmol) of compound II-1 into a 100mL dry round bottom flask, add a dry magnet and 30mL dry THF, and seal it with a rubber cork after purging with nitrogen. The flask was cooled to -78°C in liquid nitrogen-ethanol, and stirring was started. Slowly add 6.25mL (10mmol) of 1.6M n-BuLi n-hexane solution dropwise with a syringe. After the dropwise addition was complete, stirring was continued at this temperature for 1 hour. A solution of 1.44 g (10 mmol) of compound IV dissolved in 5 mL of dry THF was then added dropwise via syringe. After the dropwise addition, the reaction mixture was stirred at this temperature for 1 hour, then slowly warmed to room temperature, and stirred for 1 hour.

[0031] The reaction mixture was poured into 200mL ice water, stirred, extracted with 100mL×3 dichloromethane, the organic phases were combined, washed with saturated brine, and dried (Na 2 SO 4 ). After the desiccan...

Embodiment 2

[0033] The preparation of embodiment 21-2

[0034]

[0035] 3. Add 19g (10mmol) of compound II-2 into a 100mL dry round bottom flask, add a dry magnet and 30mL dry THF, and seal it with a rubber cork after purging with nitrogen. The flask was cooled to -78°C in liquid nitrogen-ethanol, and stirring was started. Slowly add 7.7mL (10mmol) of 1.3M sec-BuLi n-hexane solution dropwise with a syringe. After the dropwise addition was complete, stirring was continued at this temperature for 1 hour. A solution of 1.44 g (10 mmol) of compound IV dissolved in 5 mL of dry THF was then added dropwise via syringe. After the dropwise addition, the reaction mixture was stirred at this temperature for 1 hour, then slowly warmed to room temperature, and stirred for 1 hour.

[0036] The reaction mixture was poured into 200mL ice water, stirred, extracted with 100mL×3 dichloromethane, the organic phases were combined, washed with saturated brine, and dried (Na 2 SO 4 ). After the desicca...

Embodiment 3

[0038] The preparation of embodiment 31-3

[0039]

[0040] Add 2.91g (10mmol) of compound II-3 into a 100mL dry round bottom flask, add a dry magnet and 30mL dry THF, and seal it with a rubber cork after purging with nitrogen. The flask was cooled to -78°C in liquid nitrogen-ethanol, and stirring was started. Slowly add 6.25mL (10mmol) of 1.6M t-BuLi n-hexane solution dropwise with a syringe. After the dropwise addition was complete, stirring was continued at this temperature for 1 hour. A solution of 1.44 g (10 mmol) of compound IV dissolved in 5 mL of dry THF was then added dropwise via syringe. After the dropwise addition, the reaction mixture was stirred at this temperature for 1 hour, then slowly warmed to room temperature, and stirred for 1 hour.

[0041] The reaction mixture was poured into 200mL ice water, stirred, extracted with 100mL×3 dichloromethane, the organic phases were combined, washed with saturated brine, and dried (Na 2 SO 4). After the desiccant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com