Multistage ignition perforating initiation system based on digital electronic detonator using single core cable

A technology of digital electronic detonator and single-core cable, which is applied in mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as single function, poor safety, and low reliability, and achieve improved reliability and DC resistance Good impact and improved safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

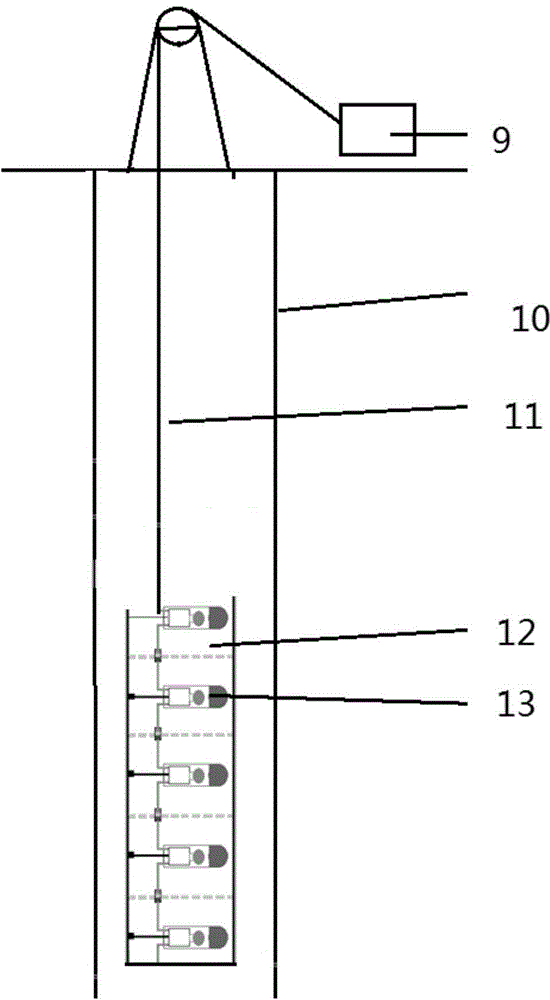

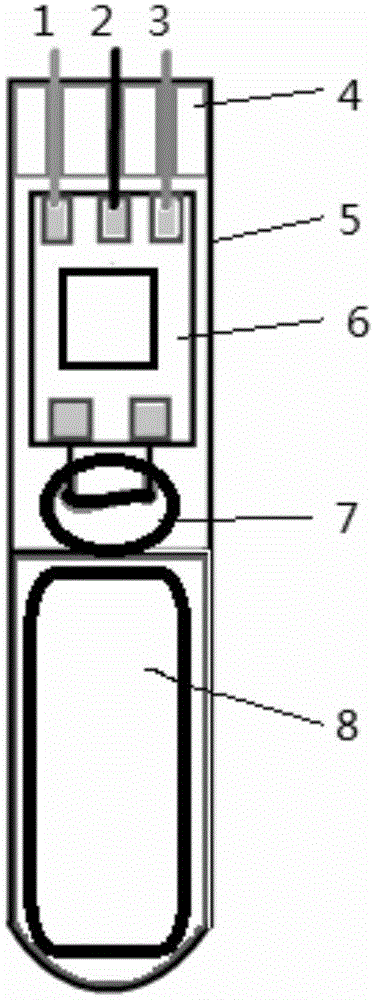

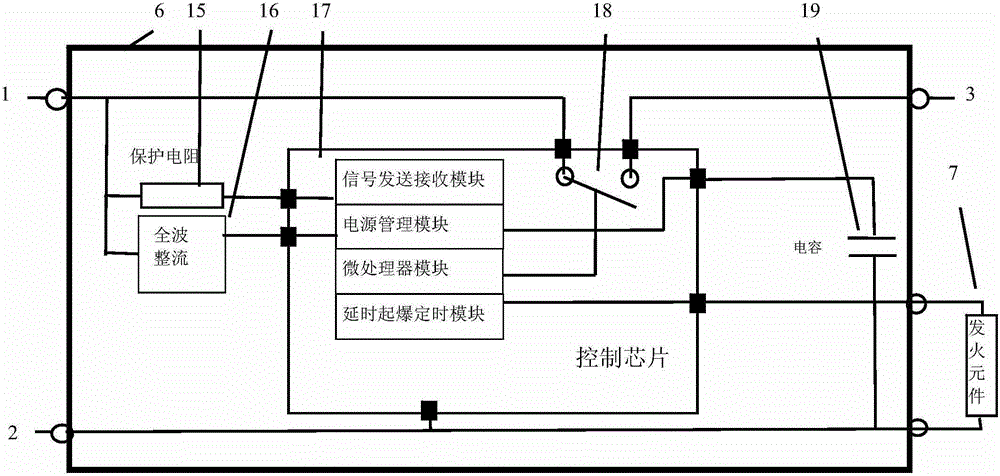

[0022] Such as figure 1 As shown, the present invention includes a multi-stage perforating unit composed of a perforating gun 12 and a digital electronic detonator 13. After the multi-stage perforating unit is connected to the cable according to the coding sequence, it is connected to the logging ground system through the ground control detonator 9; wherein The digital electronic detonator 13 of each perforating unit includes the basic detonator 8 encapsulated in the tube shell 5 and the ignition element 7 connected to the electronic control module 6. The three legs of the digital electronic detonator 13 are input leg 1 and output leg respectively. Line 3 and grounding leg 2 are respectively connected to the output leg of the pre-stage digital electronic detonator, the input leg of the rear-stage digital electronic detonator and the well wall 10; input leg 1, output leg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com