abs bearing testing machine

A bearing testing and testing machine technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of ABS bearing being unable to be tested and expensive, and achieve the effect of solving the requirements of testing and testing, meeting the needs of enterprises, and having a long-lasting application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in conjunction with accompanying drawing and specific embodiment:

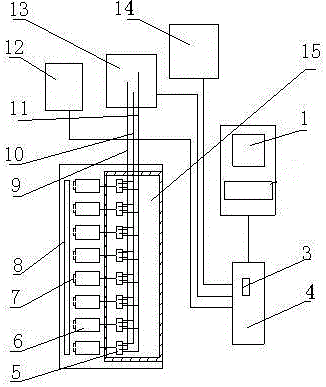

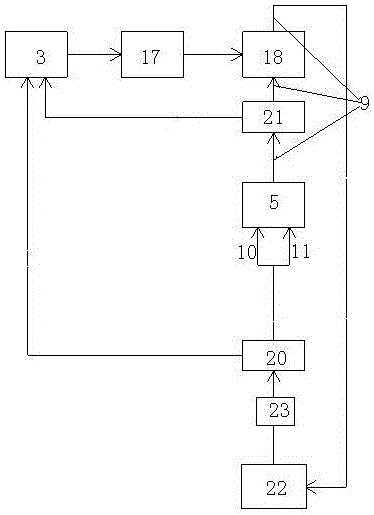

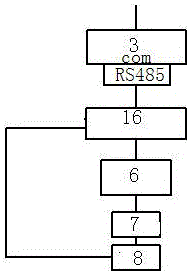

[0015] Such as figure 1 Shown, a kind of ABS bearing testing machine, described testing machine has the working box 15 in order to simulate ABS bearing to work under different ambient temperature conditions; Described working box 15 is provided with eight valve blocks 5; The valve blocks 5 are all provided with ABS bearings; corresponding to the eight described ABS bearings, there are speed control mechanisms, load control mechanisms and temperature control mechanisms for controlling the speed, load and temperature of the ABS bearings; figure 2 , the speed control mechanism includes a servo driver 16 for driving the rotation of the ABS bearing and controlling it, and the eight servo drivers 16 respectively drive eight electric spindles to rotate, and the eight electric spindles communicate with each other through flexible shafts. The ABS bearings in the eight valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com