A device and method for implementing an augmented reality induced maintenance system

A maintenance system and augmented reality technology, applied in the direction of user/computer interaction input/output, image data processing, special data processing applications, etc., can solve the problems of equipment accuracy degradation, operators' susceptibility to the surrounding environment, wear and tear, etc. To achieve the effect of increasing applicable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

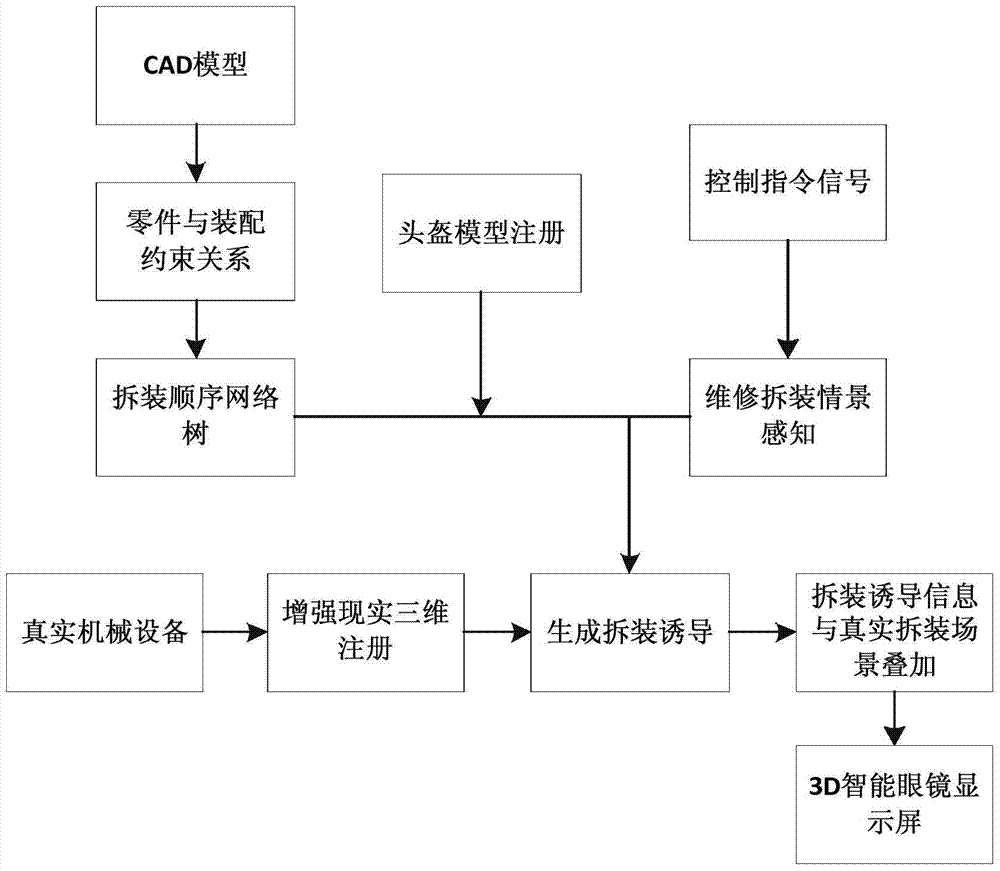

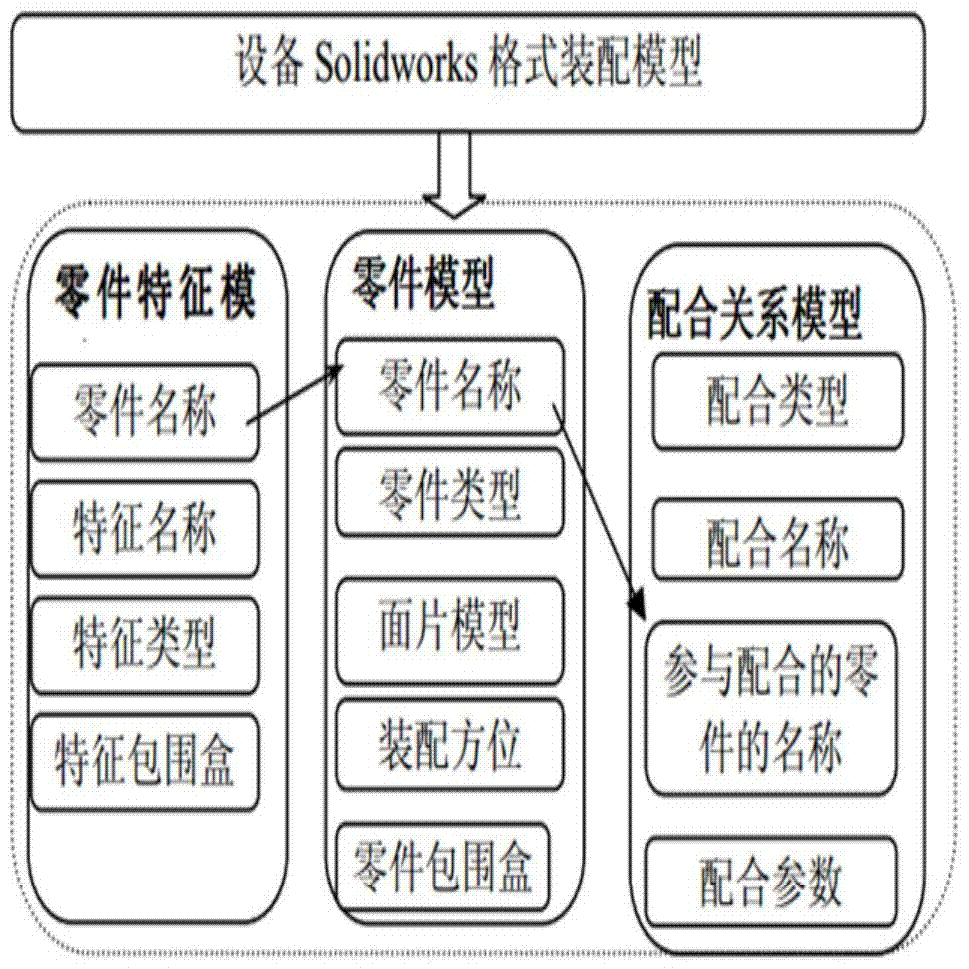

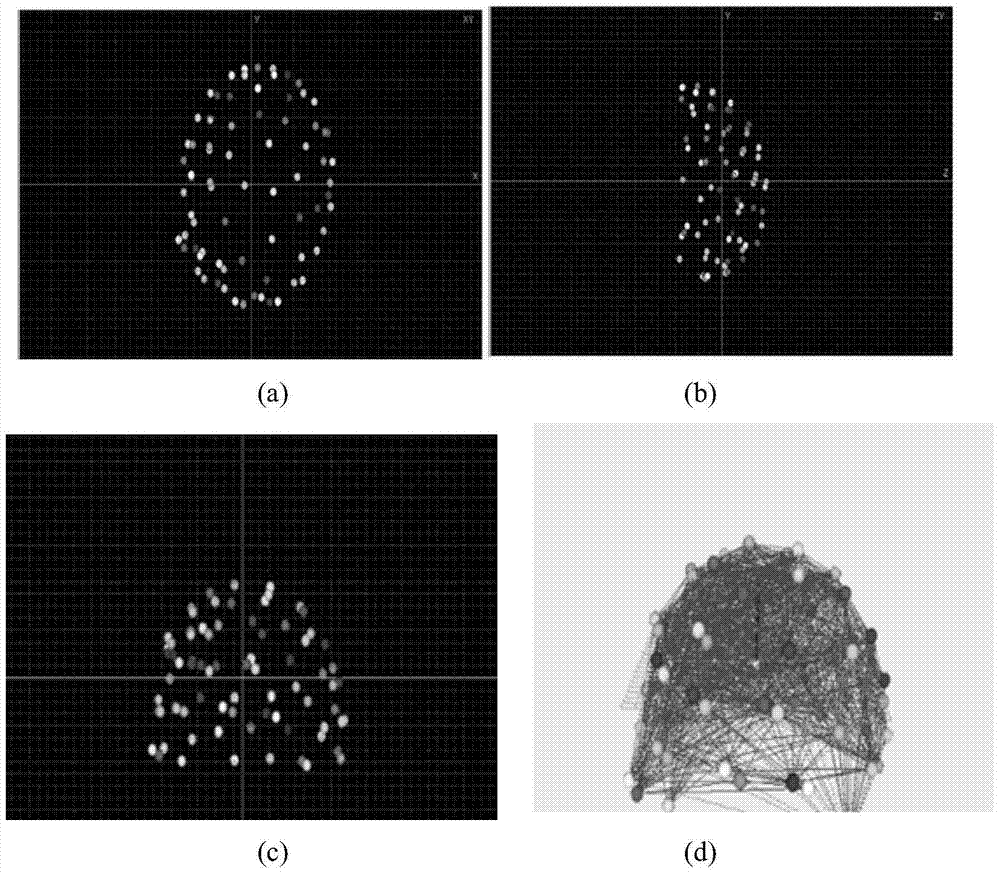

[0039]The present invention designs an augmented reality induced maintenance system. The software includes a self-developed set of component assembly induction system based on the OSG display engine, and the hardware includes a 3D smart glasses and helmet, an optical position tracker and a computer. The 3D smart glasses include two LCD screens. The optical position tracker is a 6-degree-of-freedom optical tracker. It uses wireless interactive technology for 3D interaction and uses infrared light to track objects in real time. The operator can wear and paste the logo Objects and complete position registration of the helmet, so that the optical position tracker perceives the operator's pose in the local coordinate system. The steps of the implementation method of the augmented reality induced maintenance system are as follows: Step 1: set up a virtual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com