Mechanical ground wire connecting operation platform

A technology for operating platforms and ground wires, which is applied in the direction of electrical connection sockets, clips to connect conductors, etc., can solve problems such as easy slipping of ground wire hooks, grounding accidents, difficult assembly and disassembly, etc., to achieve easy connection and disengagement, solve safety problems, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

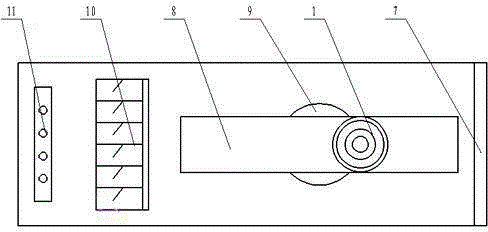

[0041] Such as figure 1 and figure 2 As shown, the present invention includes a mechanical lifting platform, a ground wire clamp 12, an electroscope five-proof position 11, a ground wire position 10, and a platform vehicle 7; On the platform car 7, the lower part is provided with universal wheels; the ground wire position 10 is installed between the five-proof position 11 of the electroscope and the guide rail 8; the five-proof position 11 of the electroscope is installed at one end of the platform car 7 , there are four holes in it, storing electroscopes with 4 voltage levels.

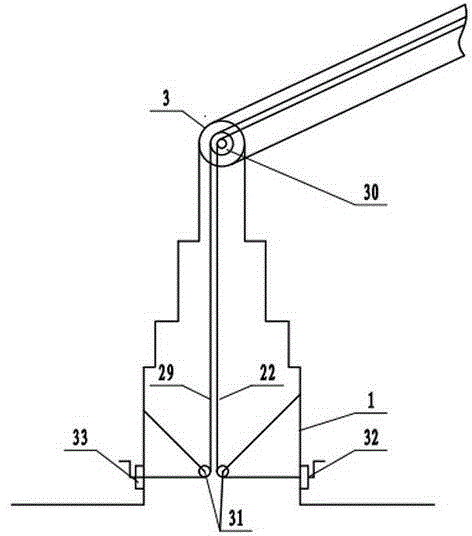

[0042] Such as image 3 As shown, the lifting platform is composed of a hollow vertical lifting rod 1 and a hollow adjustable rod head 2 connected to the vertical lifting rod 1 through an intermediate connecting shaft 3. The adjustable rod head 2 can swing up and down along the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com