Tea leaf infrared drying machine and tea leaf infrared drying method thereof

An infrared and dryer technology, applied in the direction of tea processing before extraction, can solve the problems of inability to penetrate internal moisture, dry and cracked material surface, complicated working procedures, etc., to achieve uniform effect, low dry noise, and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

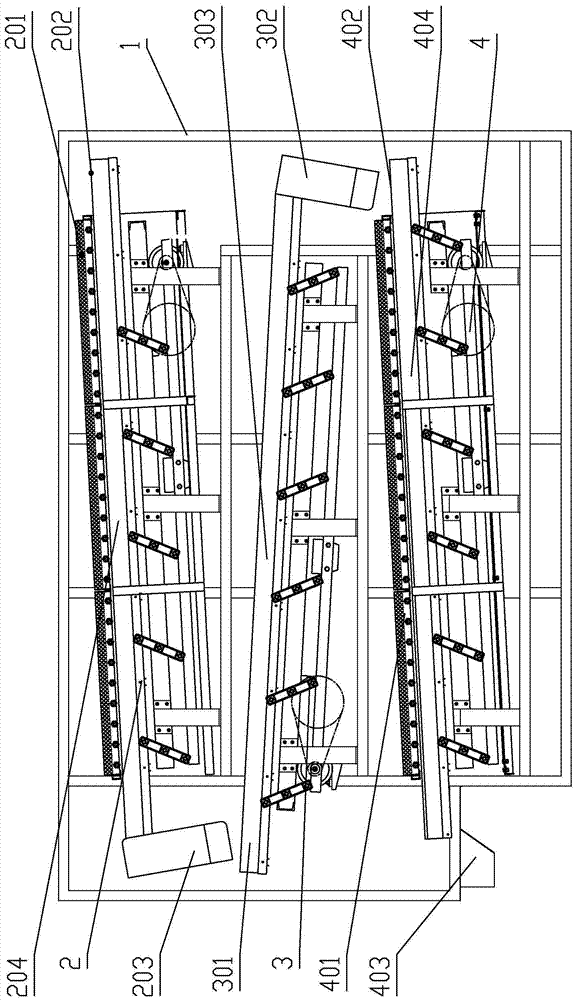

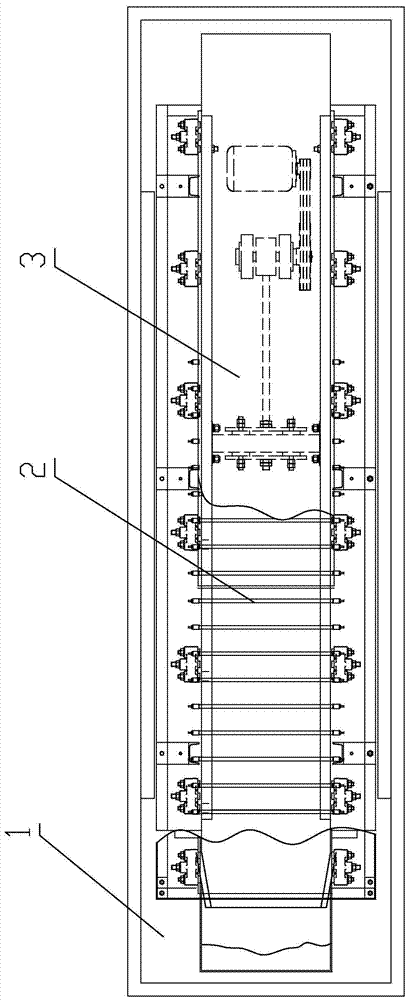

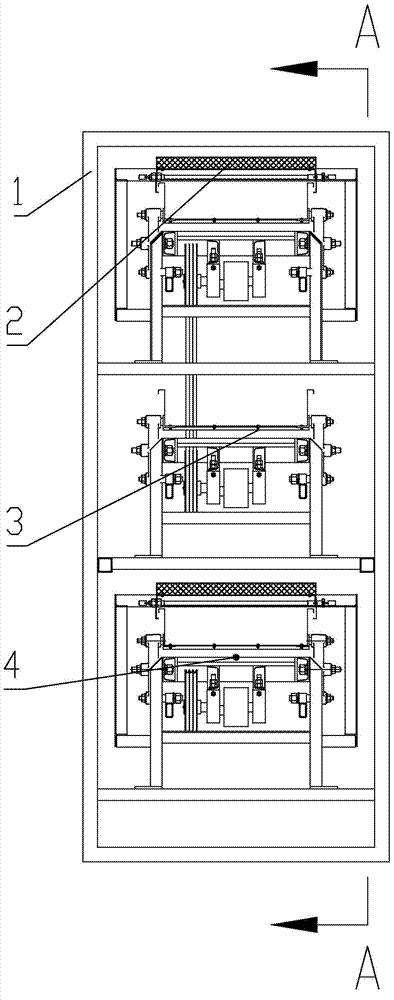

[0021] Example 1, such as figure 1 , figure 2 , image 3 Shown, the present invention mainly comprises frame case 1, upper vibration oven chamber 2, cooling moisture regain chamber 3, lower vibration oven chamber 4 and forms. The upper vibration drying tank chamber 2 is composed of an infrared heating device 201, a material inlet 202, a discharge port 203, and a vibration drying tank 204. The heating device 201 is installed above the vibration drying tank 204, and the material in the vibration drying tank Heating; the material enters the vibrating drying tank 204 from the feed port 202, and the tea leaves after the initial drying by the infrared heating device 201 flow into the next cooling moisture regain chamber 3 through the discharge port 203; The discharge port 302 and the cooling and oscillating tank 303 are composed. The material enters the cooling and oscillating tank 303 from the material receiving port 301 for cooling and moisture regain treatment, and then is dis...

Embodiment 2

[0022] Example 2, such as figure 1 As shown, the drying method and steps of this infrared dryer are:

[0023] a. The material passes through the upper vibration drying chamber 2 for initial drying;

[0024] b. After initial drying, the material is cooled through the cooling damp chamber 3;

[0025] c. After cooling and regaining moisture, the material flows through the lower vibration drying chamber 4 for secondary drying;

[0026] d. When the material flows through the process of the upper vibrating drying chamber 2, the cooling moisture regaining chamber 3, and the lower vibrating drying chamber 4, it is all dried under the state of dynamic tumbling and conveyed, and the intermediate cooling and moisture regaining treatment is carried out to reach the material The process of fast drying and fast cooling ensures the good quality of the items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com