Multipurpose small rectification system for laboratory

A laboratory and rectification system technology, applied in the field of multi-purpose laboratory small rectification systems, can solve the problems of uneven liquid distribution, decreased tray efficiency, limited effective packing height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

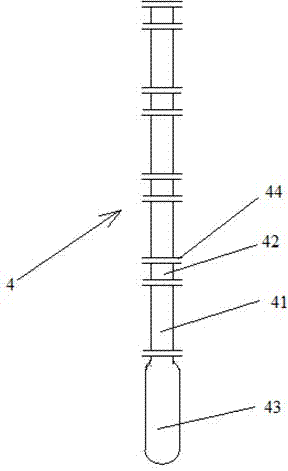

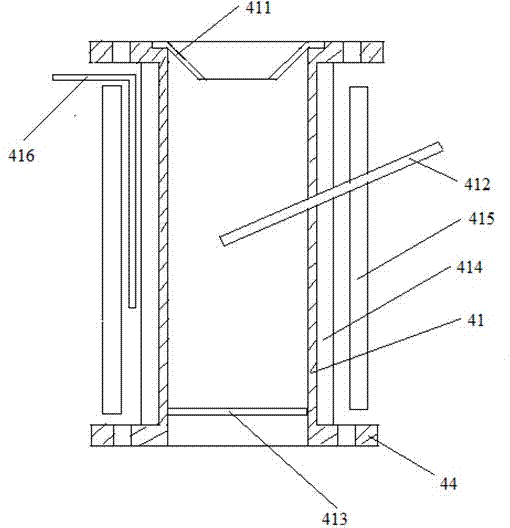

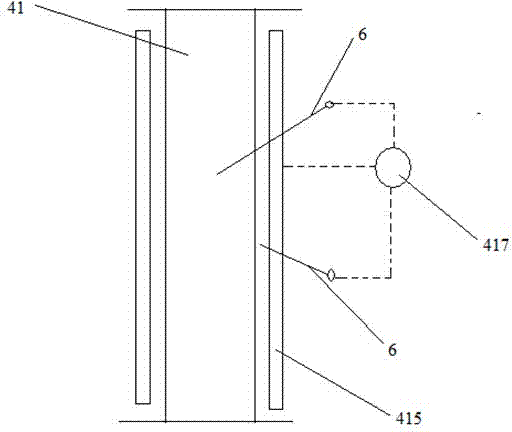

[0048] figure 1 The multi-purpose laboratory small-scale rectification system shown is an embodiment of the present invention, including a feed device and a rectification column 4 connected in series with each other. There are two sets of feeding devices, namely the first feeding device and the second feeding device. The first feeding device includes a raw material tank 1, a raw material pump 2 and a preheating furnace 3 connected in series by a pipeline in sequence, and the second feeding device includes a raw material tank 1', a raw material pump 2' and a preheating furnace connected in series by a pipeline in sequence 3'. Both the preheating furnace 3 and the preheating furnace 3' are equipped with a temperature controller 5, and the temperature controller 5 receives the temperature information fed back by the thermometer 6 at the outlet of the preheating furnace to adjust the heating temperature of the preheating furnace.

[0049] The rectification column 4 includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com