Horizontal permanent magnet synchronous submersible motor assembly machine production operation assembly line

A permanent magnet synchronous and motor unit technology, which is applied to electromechanical devices, electric components, and manufacturing motor generators, etc., can solve the problems of cumbersome assembly of production lines and cannot meet the needs of production, and achieves easy promotion, low cost, and application. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

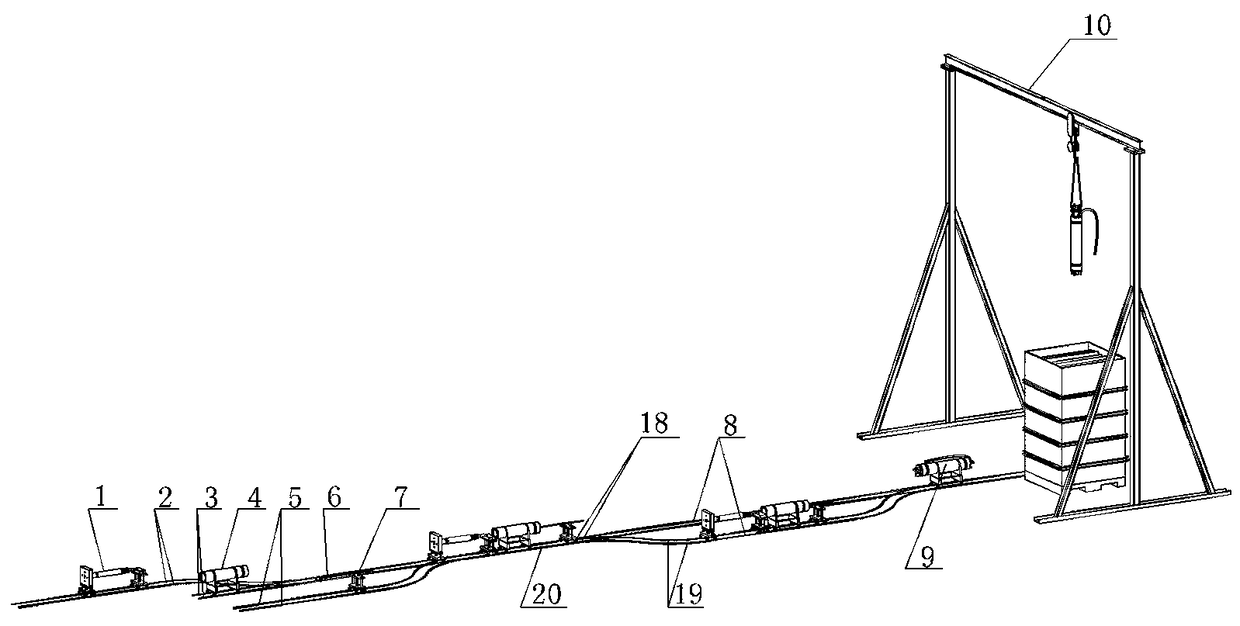

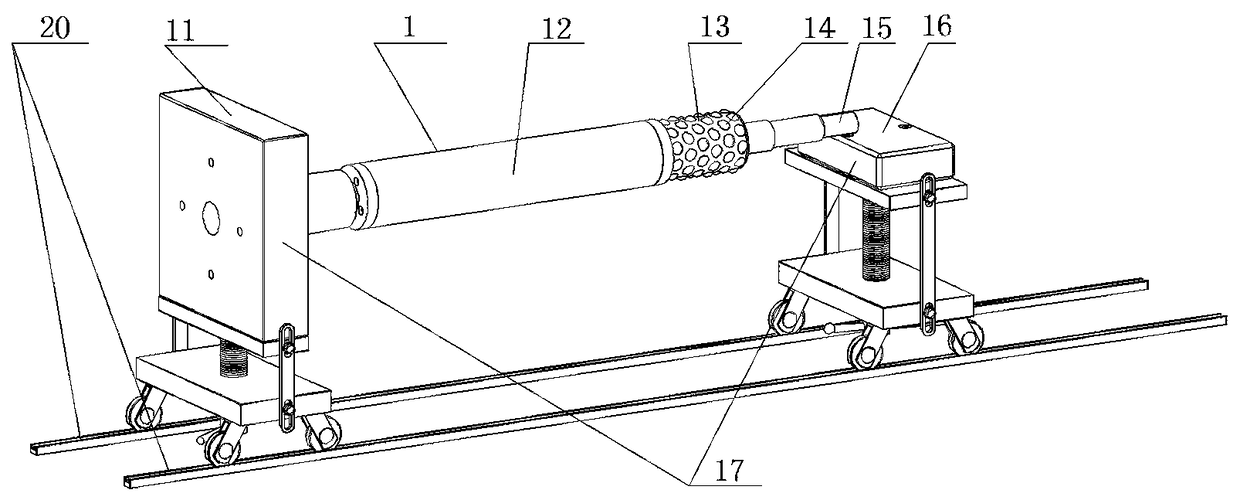

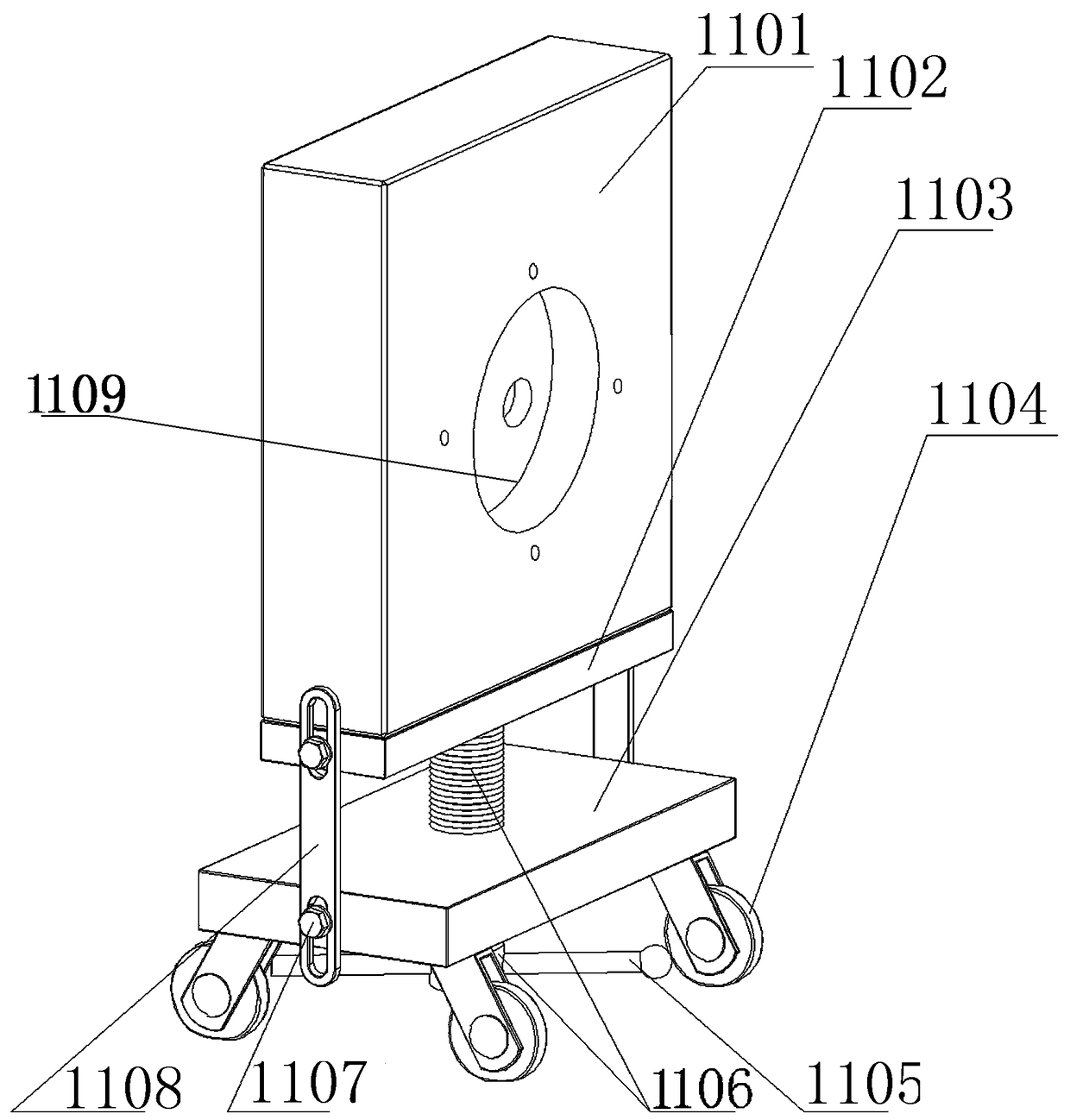

[0037] Attached figure 1 As shown, the production line of a horizontal permanent magnet synchronous submersible motor assembly machine of the present invention includes a track 20, a rotor station 1, a stator station 4, a rotor coaxial fixture station 7, a test device 10, and the track 20 The front end is docked with the test device 10. The rotor station 1, the stator station 4, and the rotor coaxial fixture station 7 are respectively installed on the track 20 and can be moved on the track 20; the rotor coaxial fixture is installed through the track 20 Station 7, stator station 4, and rotor station 1 are sequentially transported to the designated assembly area 8 on the front of the track 20. In the designated assembly area 8, from front to back are rotor coaxial fixture station 7, stator station 4 , Rotor station 1; in the designated assembly area 8, the rotor coaxial fixture station 7, the stator station 4, and the rotor station 1 are assembled together to form a submersible mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com