Insulation body for an electrical machine

A technology of insulating body and body, applied in the direction of winding insulation material, shape/style/structure of winding insulation, electric components, etc., can solve problems such as electrical short circuit, large structural complexity, adverse impact of motor production cost, etc., to achieve low manufacturing cost Cost, effect of strong cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

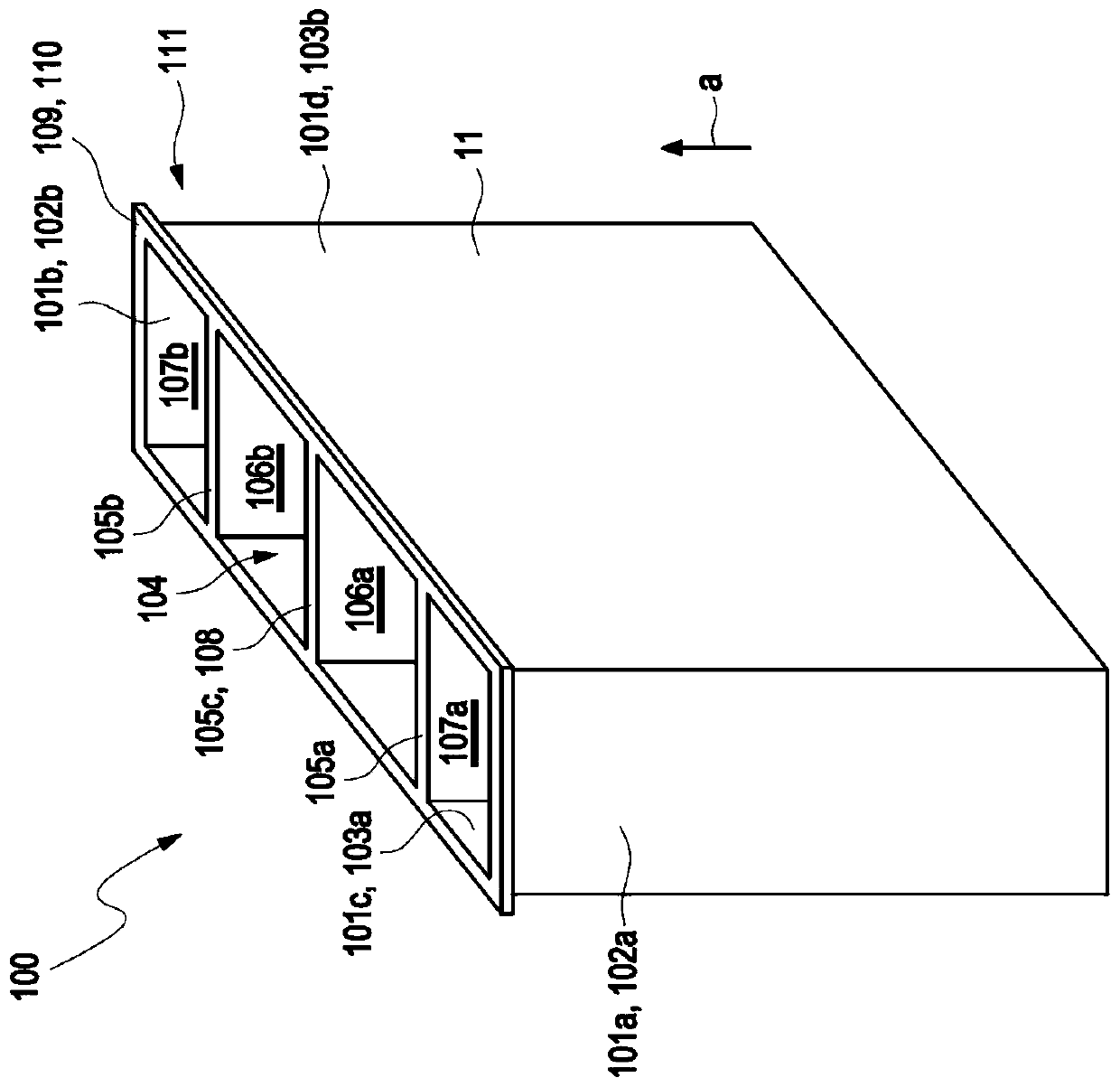

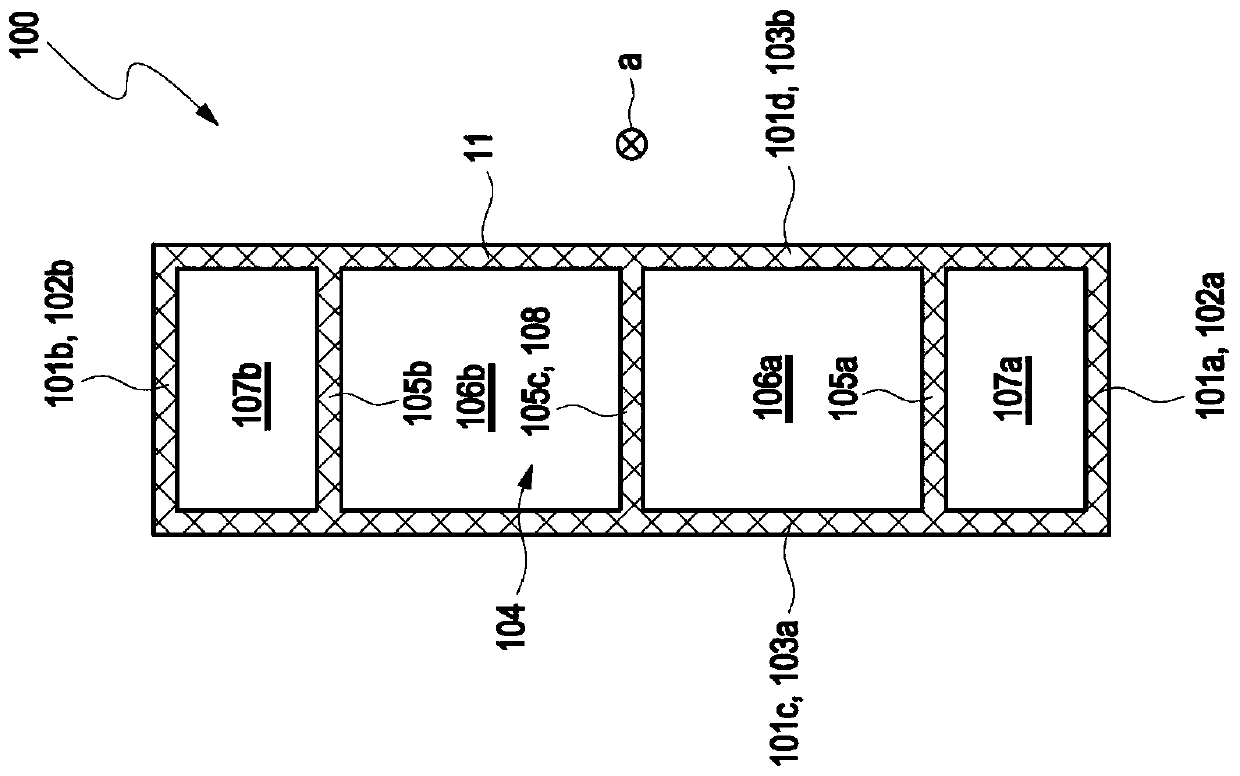

[0064] figure 1 and figure 2 An example of an insulating body 100 according to the invention is shown, which consists of a plastic 11 for a stator of an electric machine. Advantageously, the insulating body 100 is an injection molded part. Additionally, the insulating body 100 may be a unitary body, and alternatively or additionally, an extruded body.

[0065] figure 1 The insulating body 100 is shown in isometric view, and figure 2 The insulating body 100 is shown in cross-section. The insulating body 100 defines a body interior 104 . according to figure 1 , the insulating body 100 has a parallelepiped geometry. The parallelepiped is formed by four outer walls 101 a , 101 b , 101 d made of plastic 11 . The four outer walls 101a-d extend along the axial direction a. In a cross section perpendicular to the axial direction a, as figure 2 As shown in , the outer walls 101a-d form two narrow sides 102a, 102b and two broad sides 103a, 103b. The two narrow sides 102a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com