Bottle washing equipment

A technology for washing bottles and equipment, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low production efficiency, and achieve the effects of improving efficiency, saving time, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

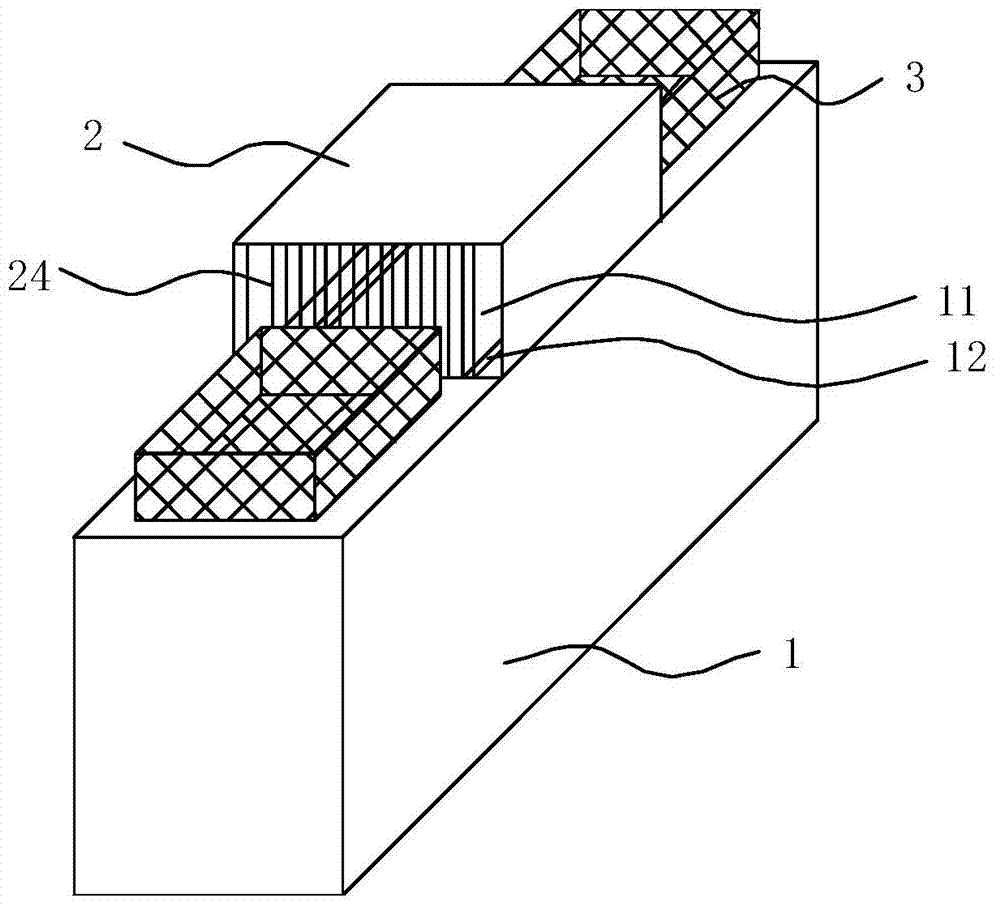

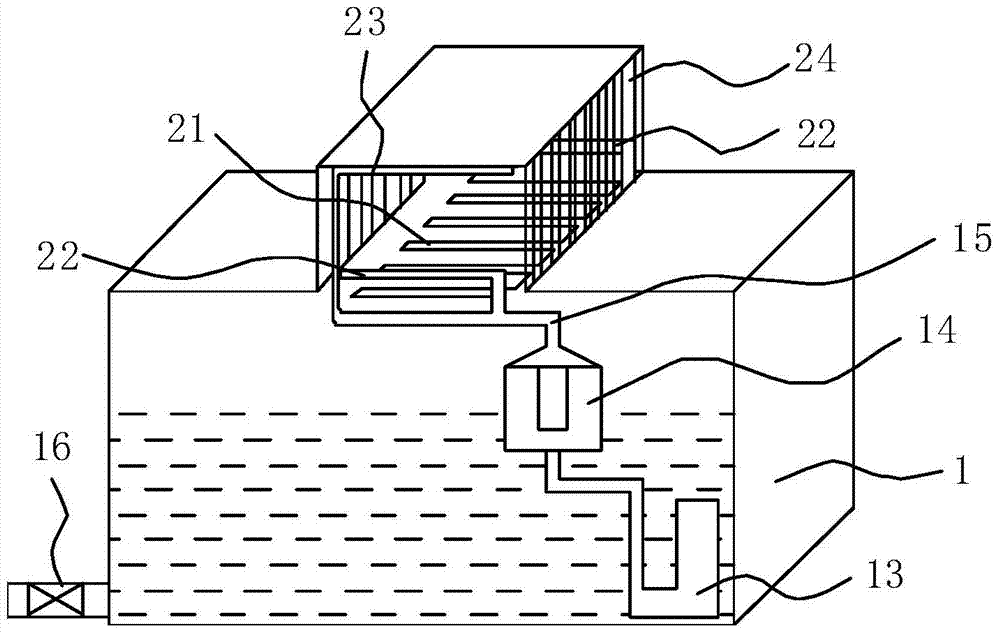

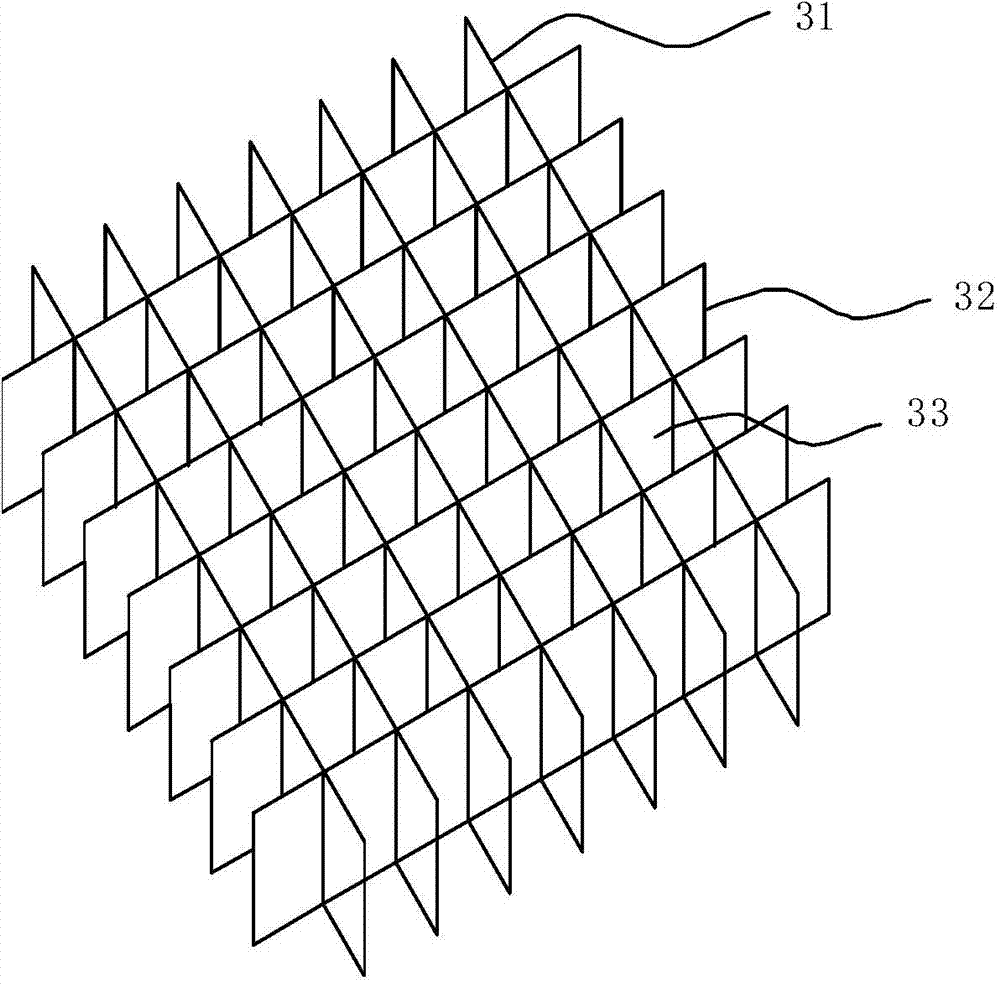

[0023] Such as Figure 1-3 The shown bottle washing equipment comprises a square water tank 1, a square spray chamber 2 and a square screen frame 3.

[0024] The top of the water tank 1 has a window 11, and the window 11 is provided with two poles 12 parallel to the window. One side moves to the guide rail of the other side; High-pressure water pump 13 is positioned at water tank 1 bottom, connects the filter 14 in the water tank, and filter 14 is sand filter;

[0025] The spray chamber 2 is located above the window 11. One side opening of the spray chamber 2 forms the entrance of the screen frame, and the opening on the other side forms the exit of the screen frame. The screen frame 3 can be pushed into the spray chamber 2 by the entrance of the screen frame, and then passes along the track The screen frame outlet pushes out the spray chamber 2; the screen frame inlet and the screen frame outlet are provided with a waterproof curtain 24 that stops the lotion from splashing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com