Automobile hinge integration welding device with high utilization rate

A welding device and utilization technology, applied in the field of high-utilization automobile hinge integrated welding device, can solve the problems of inventory waste, waiting time waste, waste of defective products, etc., to improve equipment utilization, meet delivery requirements, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

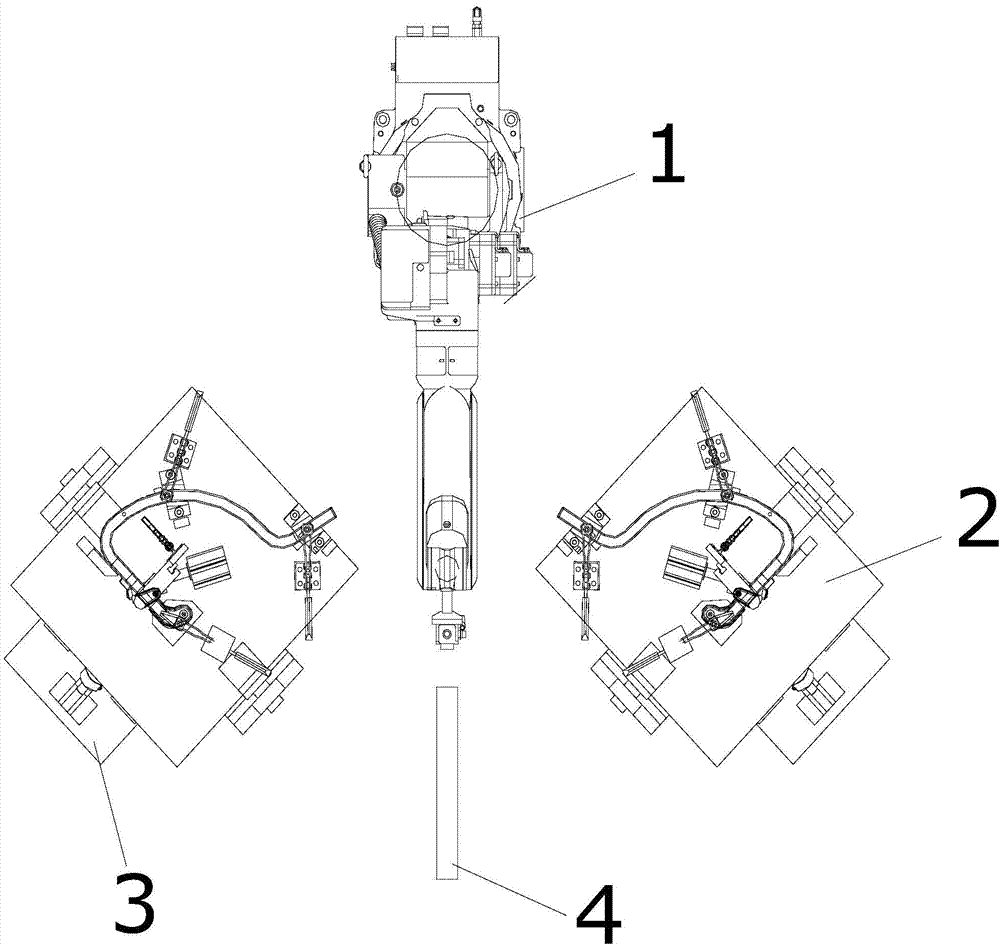

[0018] like figure 1 As shown, a high utilization ratio automobile hinge integrated welding device includes a welding robot 1, a left welding jig 3, a right welding jig 2 and a middle isolation protection plate 4, and the left welding jig 3 and the right welding The fixtures 2 are respectively arranged on both sides of the welding robot 1 , and the middle isolation protection plate 4 is arranged in the middle of the left welding fixture 3 and the right welding fixture 2 .

[0019] Described welding robot 1 comprises fixed base, robot body, welding arm and welding torch, and described robot body is fixed on the fixed base, and described welding arm is installed on robot body, and described welding torch is fixed on the welding arm .

[0020] Both the left welding jig 3 and the right welding jig 2 include a jig base, a positioning block and a chuck, and the positioning block and the chuck are installed on the jig base.

[0021] The middle isolation protection plate 4 is a mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com