Stainless steel tableware machining technology

A processing technology and stainless steel technology, applied in the field of stainless steel tableware processing technology, can solve the problems of burrs, incomplete removal of sharp edges, products are not easy to clamp, and products cannot be polished, etc., achieving good machine grinding effect, easy clamping, Good quality product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

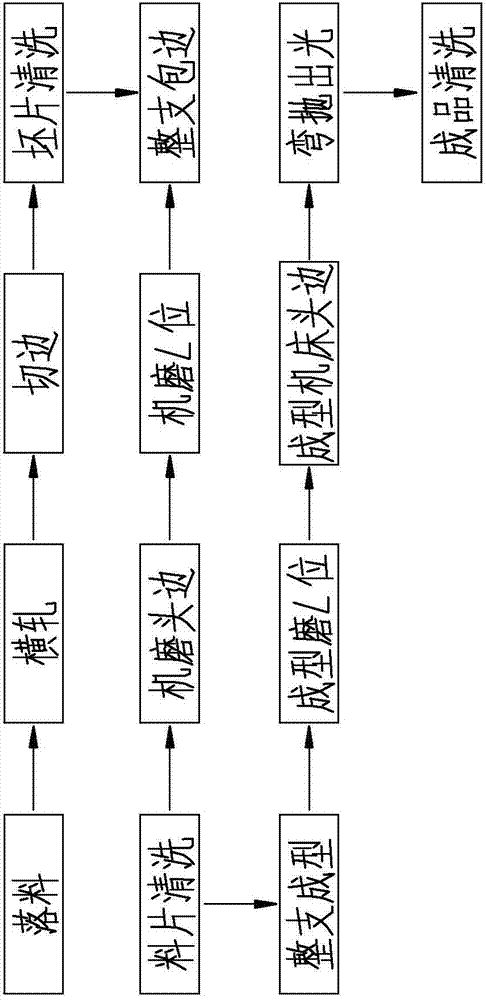

[0020] Such as figure 1 As shown, the processing technology of stainless steel tableware includes the following steps in sequence: blanking / typing, automatic cross rolling, automatic edge trimming, blank cleaning, whole piece edge wrapping, machine grinding L position, machine grinding head edge, blank cleaning, whole piece Forming, forming grinding L position, forming machine edging, bending and polishing, and finished product cleaning, and finally the finished product is packaged.

[0021] This processing technology is suitable for stainless steel tableware such as knives, forks, spoons, etc. The following is the processing of stainless steel spoons as an example: thin stainless steel plates are selected as raw materials, and the processing process is as follows: 80T or 125T precision punching machine, blanking die, three-in-one automatic The feeder punches and blanks the blanks according to the design requirements of the drawings to obtain the blanks. It is required that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com