Embedded pipe elbow pipe device

A technology of a pipe bending device and a pre-embedded pipe, which is applied in the field of building materials installation tools, can solve the problems of reducing the quality of pre-embedding, inconvenience for users, and increasing the difficulty of threading, and achieves the effect of improving the quality of pre-embedding and determining the position accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

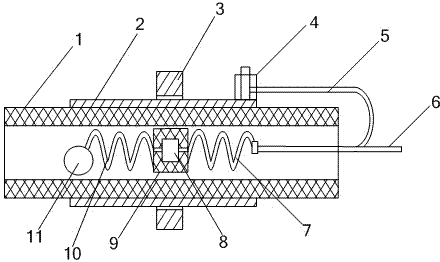

[0012] Such as figure 1 The shown pre-embedded pipe bending device includes a first bend spring 10, a second bend spring 7, a non-magnetic slide pipe 2, a magnetic ring 3 and a magnet block 8 that can pass through the inside of the embedded pipe 1. The sliding tube 2 is sleeved on the outer wall of the pre-embedded tube 1, the magnetic ring 3 is sleeved on the outer surface of the sliding tube 2 and realizes sliding connection, and the magnet block 8 is arranged on the first elbow spring 10 and the second elbow spring 7, a flexible rope 5 is arranged between the second curved tube spring 7 and the sliding tube 2, the end of the second curved tube spring 7 is connected with a push-pull rod 6, and the outer layer of the magnet block 8 is wrapped with a deformed Rubber block9.

[0013] The magnet block 8 is arranged between the first elbow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com