Steering system of full-electric piling car

A technology of steering system and stacker truck, which is applied in the field of steering system of all electric vehicles, can solve the problems of poor operability and achieve the effects of flexible centering, reliable action and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

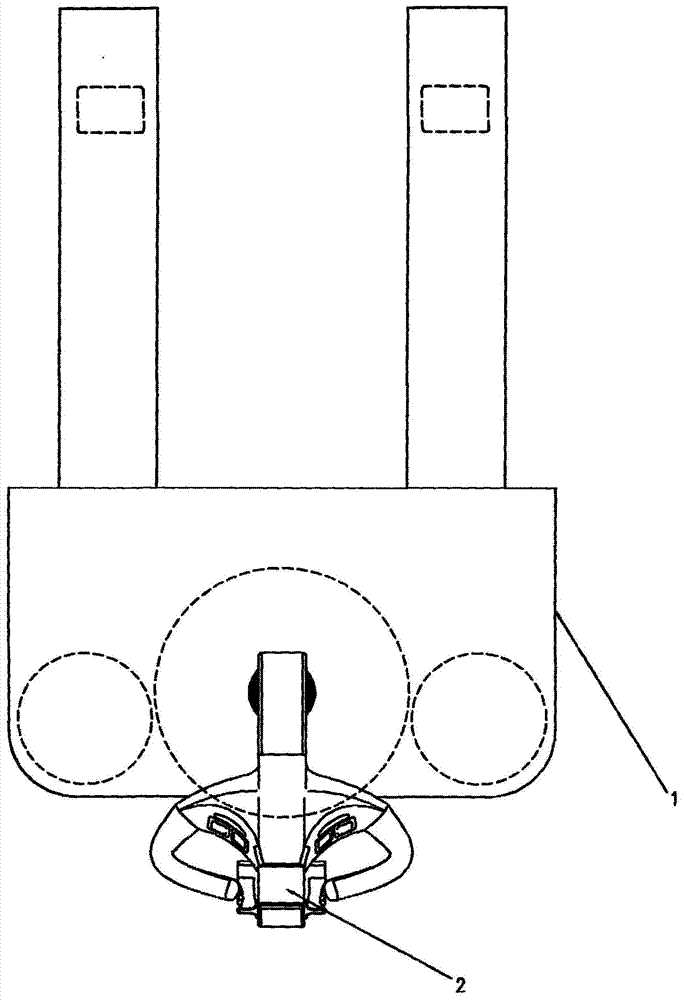

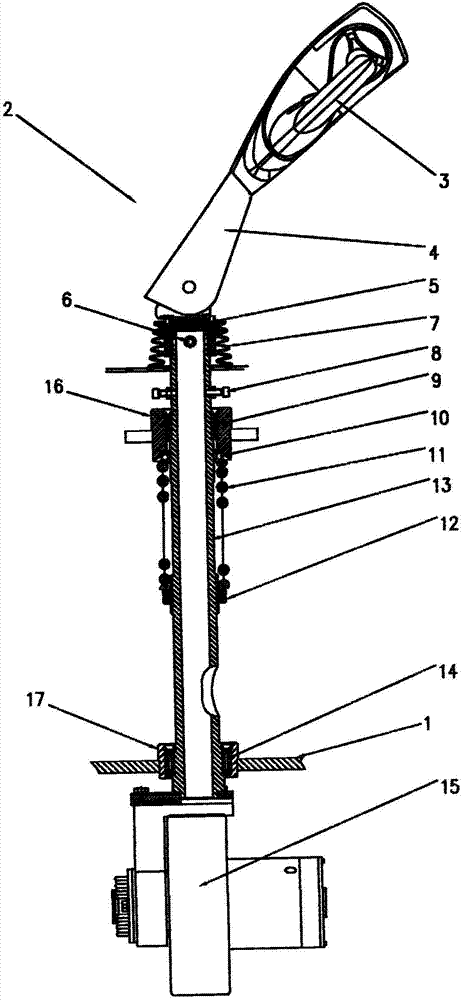

[0022] Such as figure 1 and 2 As shown, the all-electric stacker truck steering system described in the embodiment of the present invention includes an operating rudder 3, an operating connecting rod 4, a tiller seat 5, a steering shaft 13, a driving wheel 15, an upper bushing 16 and a lower bushing 17 , the lower end of the steering shaft 13 is axially connected to the drive wheel 15, the upper end of the steering shaft 13 is locked to the tiller seat 5 through the fixing bolt 6, and the tiller seat 5 is fixed with the operating rudder 3 through the operating connecting rod 4, and the tiller seat 5 is covered with a tiller cover 7, and the tiller cover 7 buckles the junction of the tiller seat 5 and the steering shaft 13. When in use, the operating rudder 3 drives the tiller seat 5 to rotate through the operating connecting rod 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com