Intelligent sorting and warehousing system

A warehousing system and intelligent technology, applied in the field of logistics and warehousing, can solve problems such as error-prone, difficult inventory, high labor intensity, etc., to achieve the effect of ensuring assembly speed and quality, reducing labor costs, and improving site utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

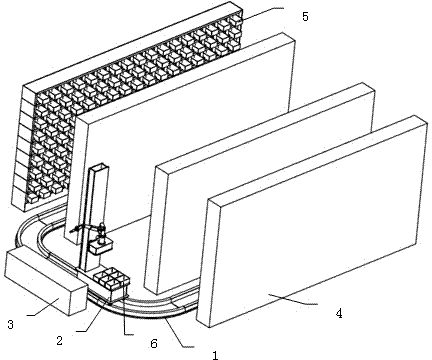

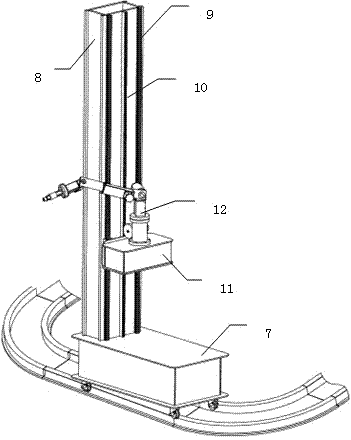

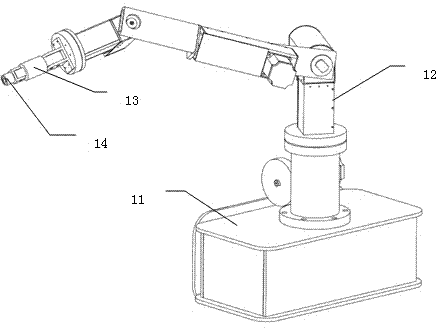

[0018] see Figures 1 to 4 , an intelligent sorting storage system, comprising 4 rows of shelves 4, rails 1, rail cars 2, a service desk 3 and a control center; the rails 1 are connected end to end and laid close to the shelves 4; There is a logistics box 5, and an induction block is installed on the shelf 4 next to the logistics box 5; the service desk 3 is arranged close to the track 1; the control center is connected to the PLC16 on the rail car 2; the rail car 2 includes a base 7 and a base The column 8 on the 7 has a turnover box 6 on the base 7, and a label is attached to the turnover box 6. The side of the column 8 has a vertical linear slide rail 9, and the side of the linear slide rail 9 has a lifting platform 11. , a manipulator 12 is arranged on the lifting table 11, and a clamp and a suction cup 14 are arranged at the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com