a loose cloth machine

A loose cloth machine and machine base technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of poor quality of finished cloth, complex structure of spreading frame, poor spreading effect, etc., to achieve Less processing failures, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

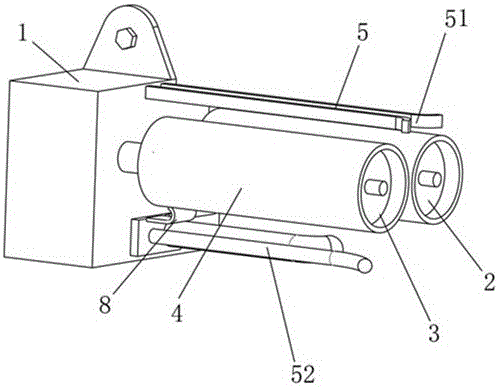

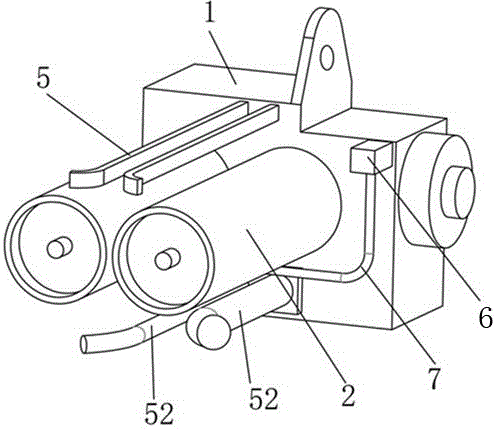

[0033] A cloth loosening machine, comprising a machine base 1 with a motor inside, and transmission and unfolding rollers arranged on the machine base for conveying and loosening cloth. The transmission roller 2 inside and the expansion roller 3 outside, the transmission roller and the roll surface of the expansion roller are the transmission channel for transmitting the cloth, and the roll surface of the expansion roller is provided with a layer of spreading layer 4, so Parallel to the conveying and unfolding rollers, the base is provided with a guide clamp bar 5 located above the conveying channel. The guide clamp bars are a pair of mirrored sets. The guide channel of the transmission channel, the rear end of the guide clamp rod is detachably fixed on the base, the front end is suspended, and the front ends of the two guide clamp rods are bent and extended in opposite directions to form a cloth inlet 51, which is located at A pair of lower guide rods 52 are arranged below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com