An electro-hydraulic proportional valve controller with sensor temperature compensation

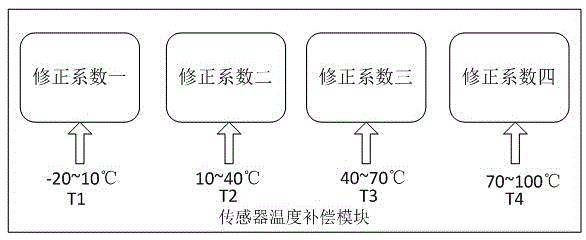

An electro-hydraulic proportional valve and temperature compensation technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of differences in sensor sensing characteristics, nonlinear discreteness of sensors, etc., to avoid cumulative errors, Improve environmental adaptability and the effect of precise digital control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

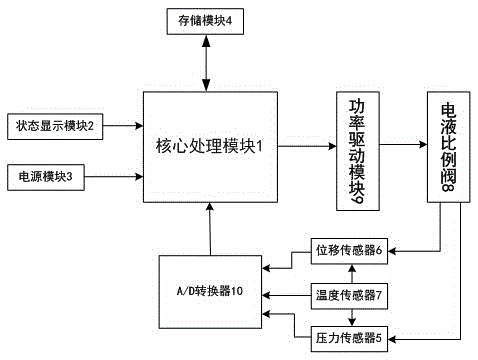

[0018] An electro-hydraulic proportional valve controller with sensor temperature compensation, comprising a storage module 4, a power module 3, a core processing module 1, a status display module 2, a power drive module 9, an electro-hydraulic proportional valve 8, a displacement sensor 6, and a temperature sensor 7 , a pressure sensor 5 and an A / D converter 10.

[0019] The state display module 2, the power drive module 9, the A / D converter 10, the storage module 4 and the power supply module 3 are all connected to the core processing module 1; the output terminal of the power drive module 9 is connected to the electro-hydraulic proportional valve 8, the pressure sensor 5 and the input of the displacement sensor 6 are connected to the electro-hydraulic proportional valve 8, the input of the temperature sensor 7 is connected to the pressure sensor 5 and the displacement sensor 6, and the output terminals of the temperature sensor 7, the pressure sensor 5 and the displacement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com