PLC servo control device and method of shaking/rotating arc welding system

A servo control device, a technology of rotating arc welding, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems such as difficult control function expansion and later maintenance, low positioning and detection accuracy, and scattered control device structure. , to achieve the effect of friendly man-machine interface, improved detection and control accuracy, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

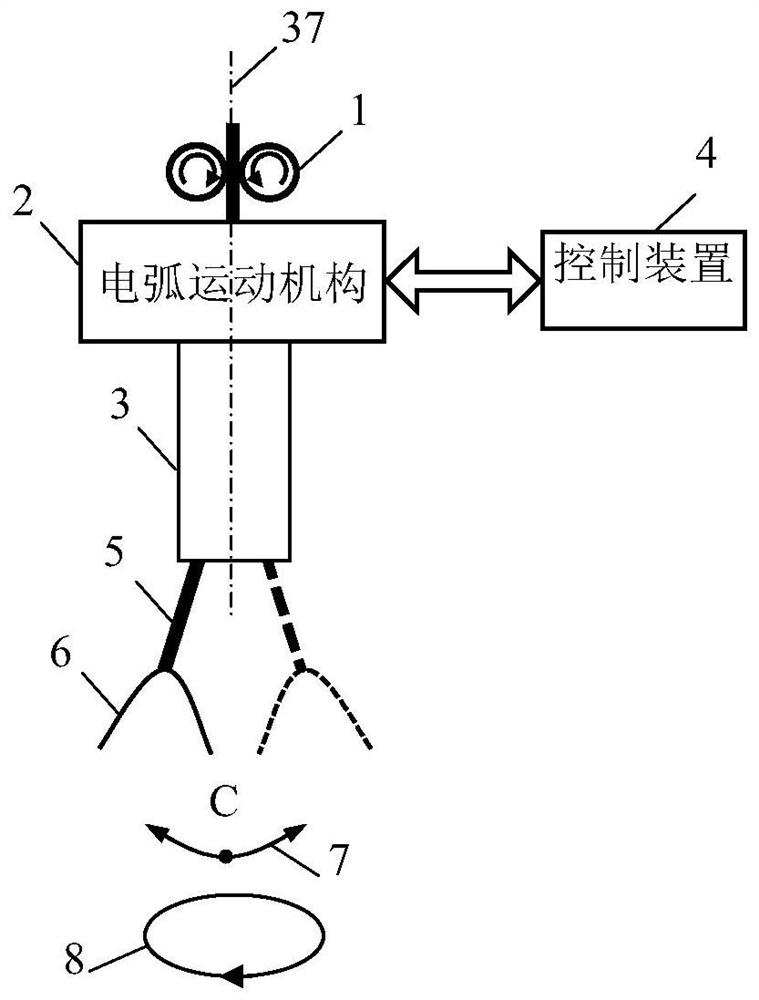

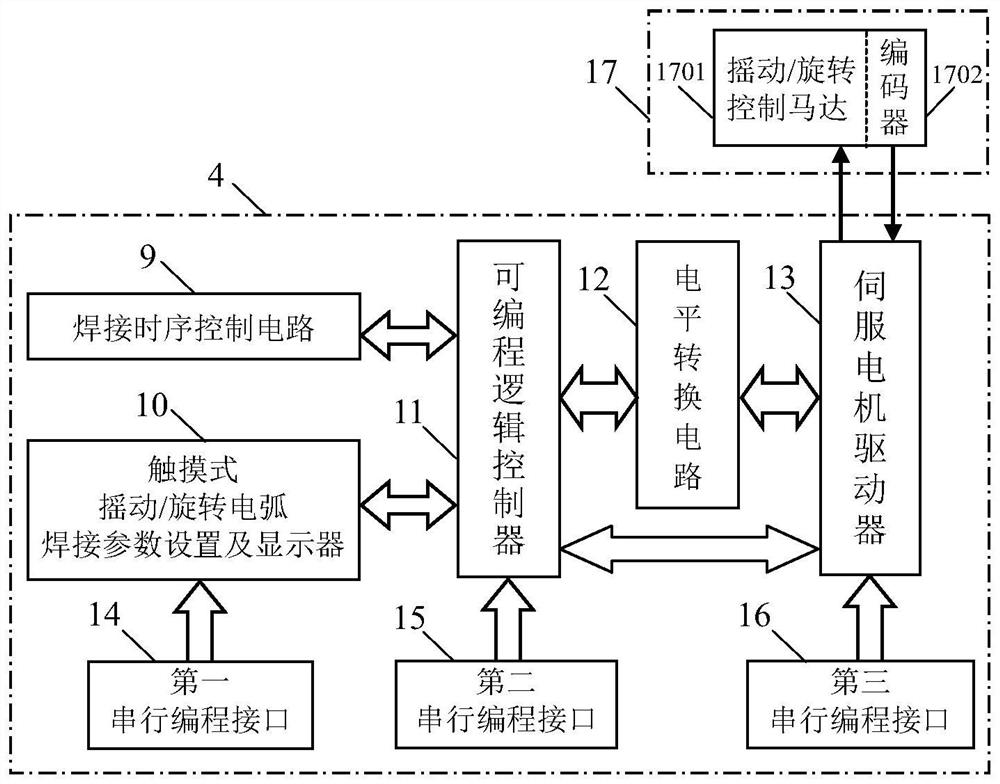

[0051] figure 1 It is the composition and schematic diagram of the shaking / rotating arc welding system. The shaking / rotating arc welding system includes a shaking / rotating arc welding torch and a PLC servo control device 4 , and the shaking / rotating arc welding torch includes an arc moving mechanism 2 and a conductive rod mechanism 3 . The welding wire 5 is sent out from the wire feeder 1, and is sent obliquely from the conductive rod mechanism 3 of the welding torch after passing through the arc moving mechanism 2; the PLC servo control device 4 controls the servo motor 17 in the arc moving mechanism 2, and then passes through its The servo motor 17 directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com