Intelligent anti-vibration three-dimensional printer for ship

A technology of 3D printers and printing mechanisms, applied in the direction of shock absorbers, supporting machines, mechanical equipment, etc., can solve problems such as inapplicability and lack of anti-vibration capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

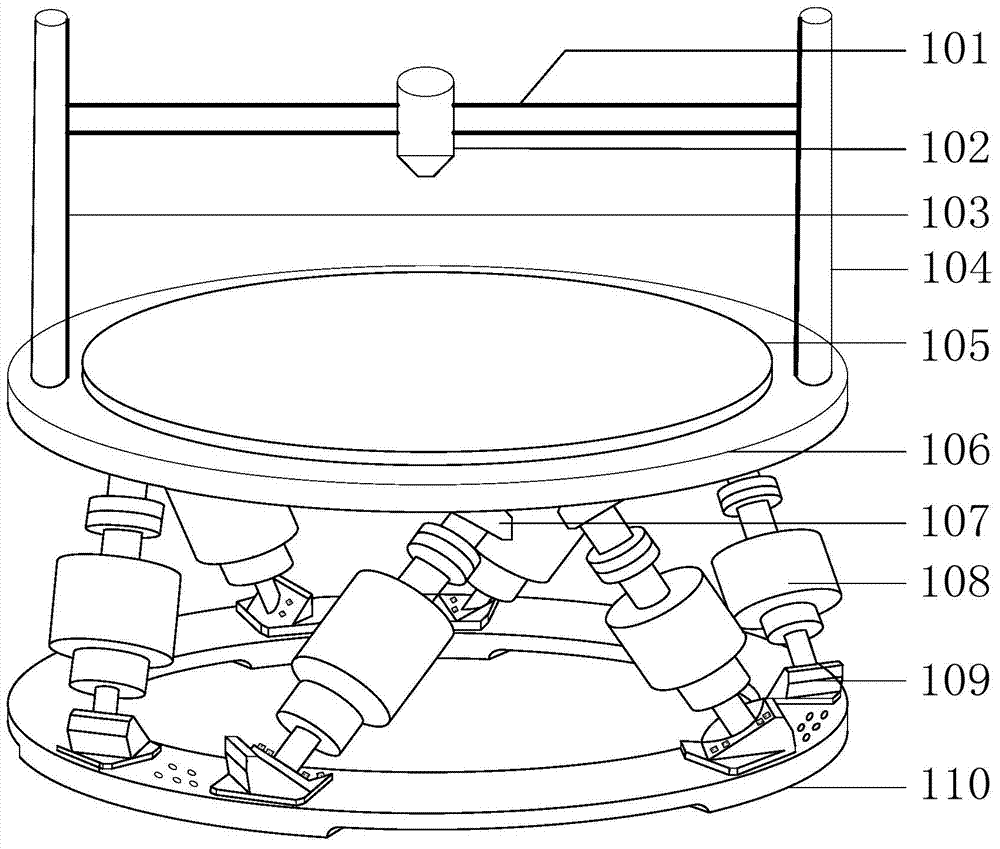

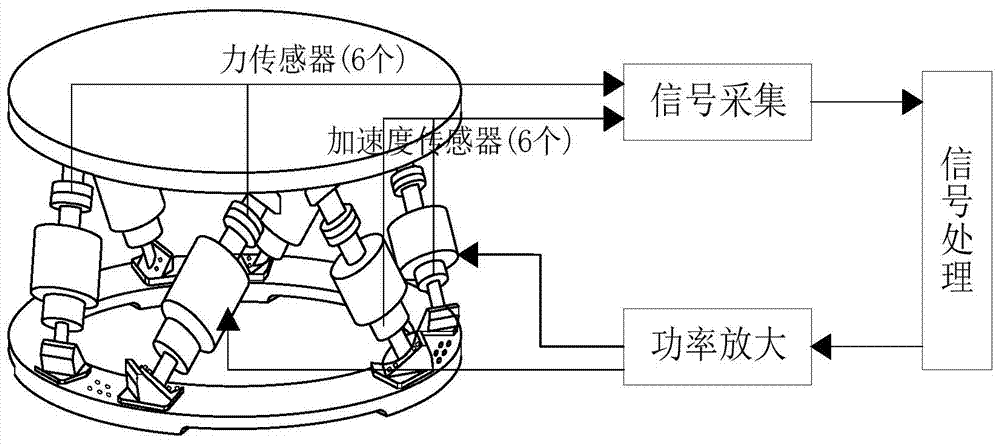

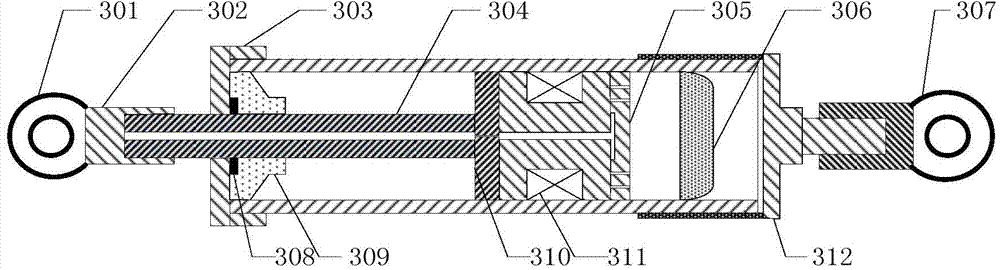

[0018] Such as figure 1 Shown is the overall structure diagram of the ship 3D printer of the present invention, including 3D printing nozzle 102, translation rod 101, lifting rod 103, lifting rod 104, turntable 105, and a six-degree-of-freedom shock-isolation platform based on the Stewart parallel mechanism.

[0019] The 3D printing nozzle 102 is used to melt the printing material and extrude the material.

[0020] The print head 102 is installed on the translation bar 101 and can slide back and forth between two ends of the translation bar 101 .

[0021] Lifting rods 103, 104 are symmetrically and fixedly installed on both sides of the platform on the six-degree-of-freedom vibration-isolation platform.

[0022] Both ends of the translation rod 101 are installed on the lifting rods 103 and 104 respectively.

[0023] The translation rod 101 is perpendicular to the lifting rods 103, 104 respectively.

[0024] The translation rod 101 can slide up and down on the lifting rods 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com