Low-temperature adsorbent device for cryogenic pressure vessel and its production process

A pressure vessel and adsorbent technology, applied in the field of low-temperature adsorbent devices, can solve the problems that the flow area has not been effectively improved, the adsorption effect is difficult to play normally, and the penetration area of the spherical sieve plate is small, so as to meet the functional requirements, Effect of reducing cracks and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

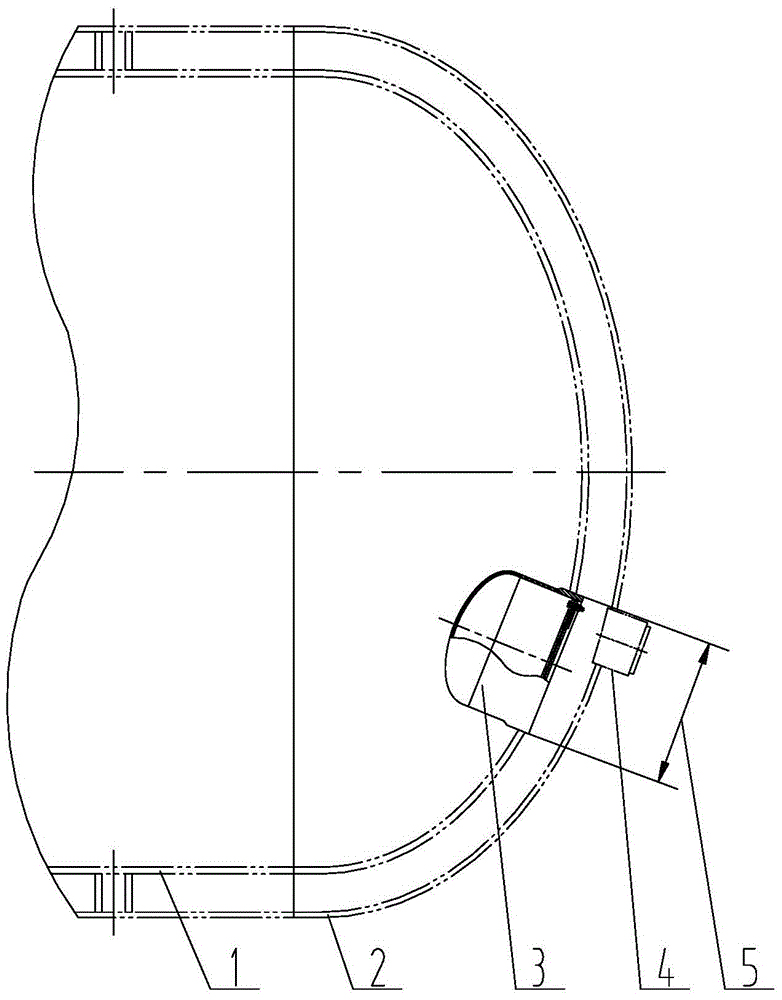

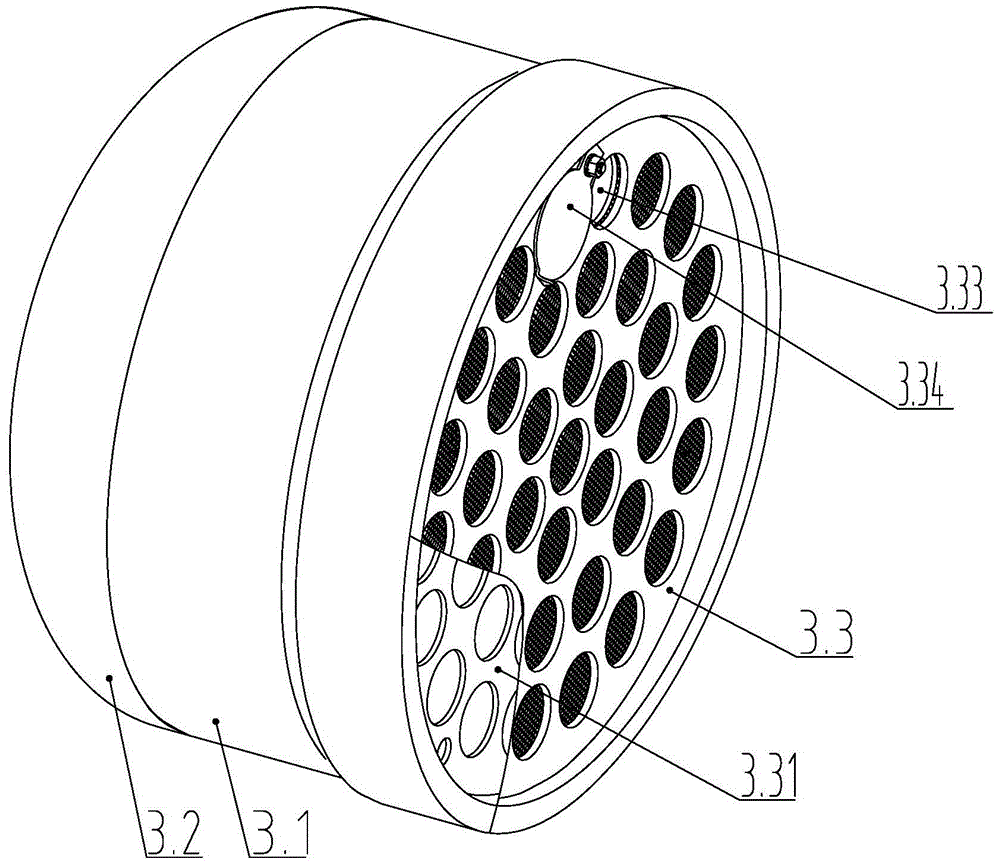

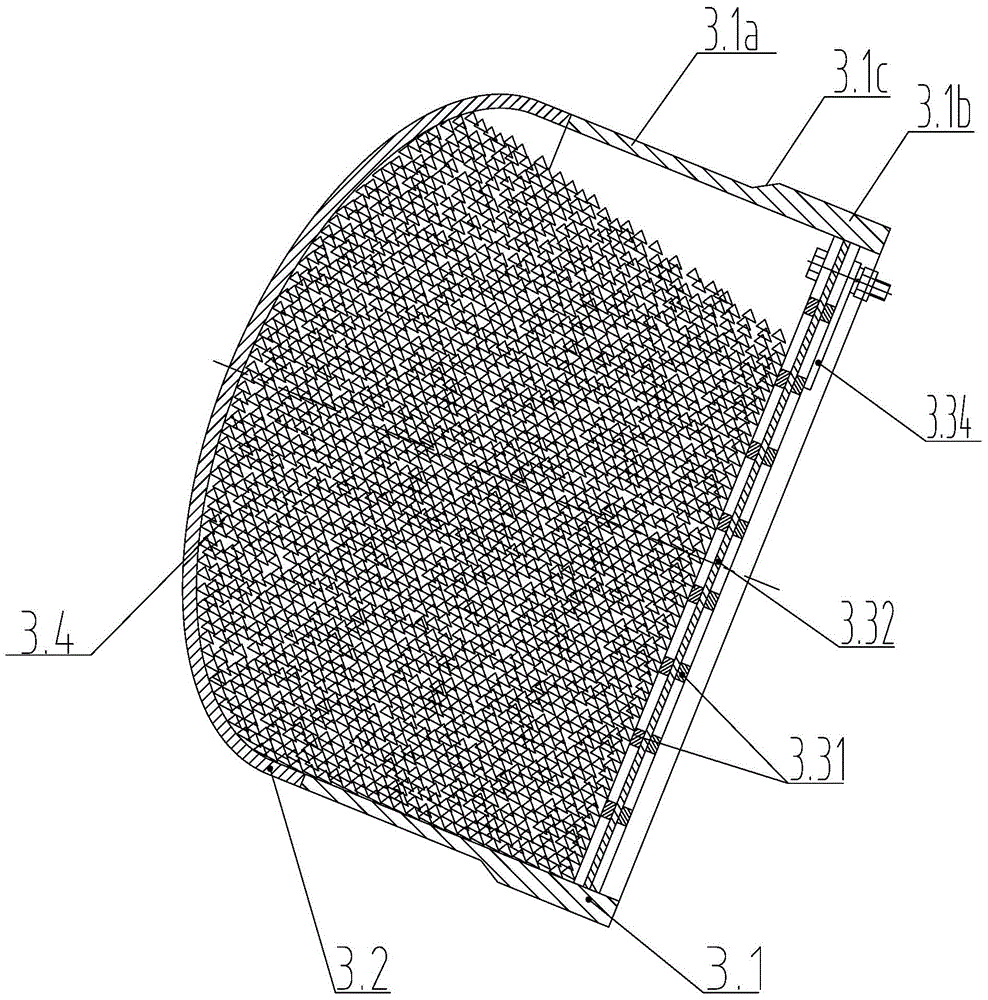

[0031] Such as Figure 1~3 The low-temperature adsorbent device used for cryogenic pressure vessel is shown, the cryogenic pressure vessel includes an inner vessel 1 and an outer vessel 2, and a process manhole 5 is opened on the middle and lower part of the head of the inner vessel 1, and the The head of the outer container 2 is provided with a feeding port 4 corresponding to the position of the process manhole 5. The low-temperature adsorbent device 3 is arranged on the process manhole 5. The low-temperature adsorbent device 3 includes an adsorbent cylinder 3.1, The adsorbent cylinder 3.1 has an upper cylinder section 3.1a and a lower cylinder section 3.1b with the same inner diameter but different outer diameters, and the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com