Electronic power catapult booster

An electronic power and booster technology, applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., to achieve the effect of stable objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

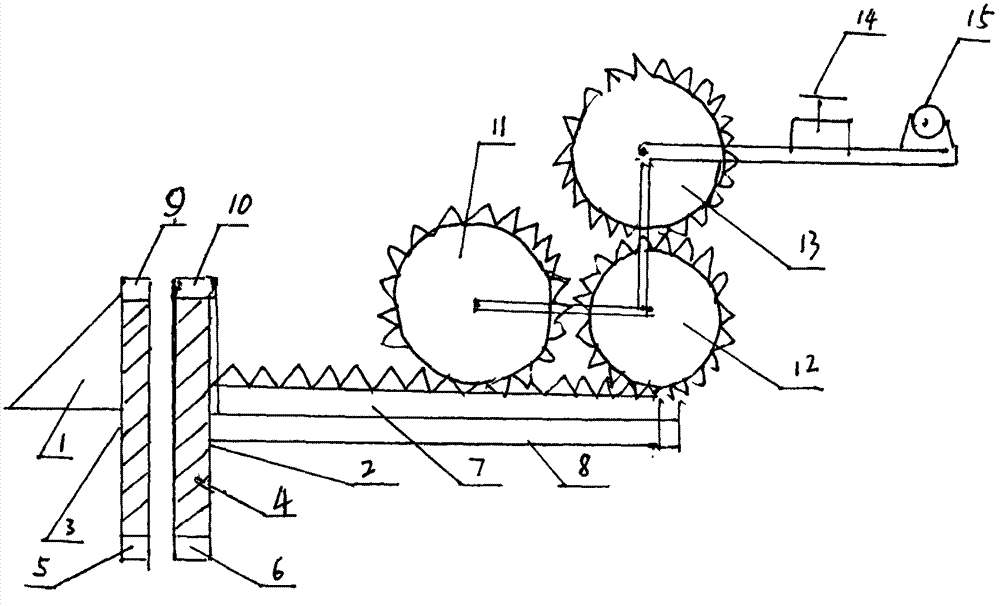

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment, as appended figure 1 The electronic power ejection booster shown, its structural setting is that two triangular baffles 1 and the plane baffle 2 are arranged in parallel, and a plane push rod 7 is arranged perpendicular to the plane baffle 2, under the plane rack push rod 7 and The push rubber air cushion 8 is arranged in parallel, the rack push rod 7 is toothed and connected to the driven wheel 11, the driving wheel 11 is toothed and connected to the driven wheel 12, the driven wheel 12 is toothed and connected to the driving wheel 13, and the driving wheel 13 is connected to the motor through the transmission 14 15. The main body of the triangular baffle 1 is set as an electromagnet A3, the upper part is provided with a clamping electromagnet card A9, the lower part is provided with a coil A5, the main body of the plane baffle 2 is set as an electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com