Buried pipeline temperature measuring method

A technology for buried pipelines and temperature measurement, which is applied to thermometers, measuring devices, and heat measurement. It can solve problems such as low measurement accuracy, poor safety or stability, and high maintenance costs, and achieve investment savings, easy maintenance and operation, and prevent rainwater. entry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

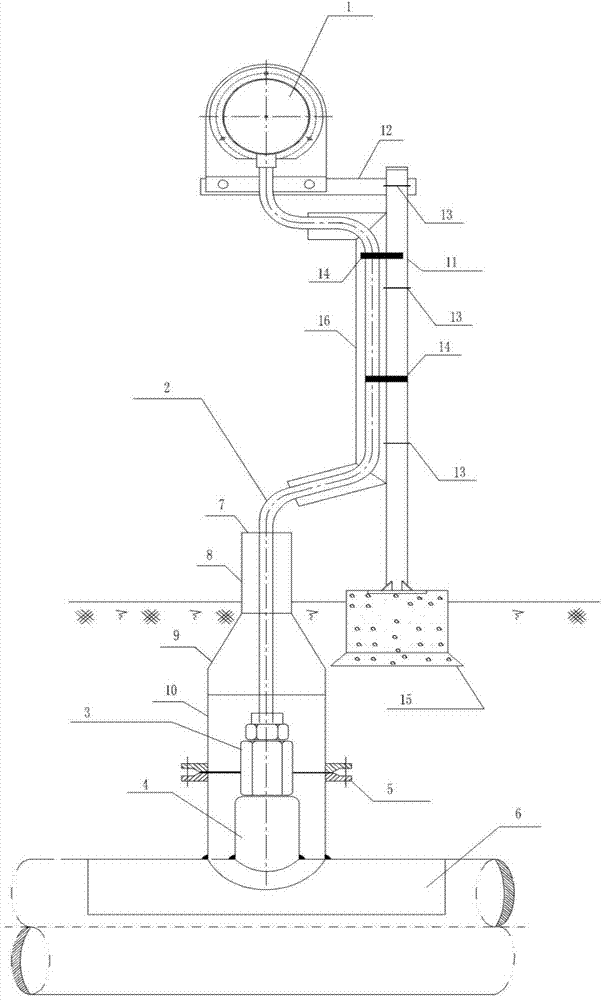

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] see figure 1 , the embodiment of the present invention provides a buried pipeline temperature measurement method, which consists of a plug-in thermometer 1, a capillary tube 2, a thermometer outer protective sleeve 3, a threaded boss 4, a protective steel pipe, a sealing block 7, a mounting bracket 11 and The cable trough box 16 is composed of, and the specific measurement process includes: welding the threaded boss 4 on the buried pipeline 6, the threaded end of the threaded boss 4 and the outer protective sleeve 3 of the thermometer are connected by threads; one end of the mounting bracket 11 passes through the concrete foundation 15 It is fixed on the ground, and the other end is fixed with a plug-in thermometer 1; the cable box 16 is fixed on the mounting bracket 11; The casing 3 is connected; the protective steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com