Method for reducing failure number of coal ash weight-loss weigher

A technology of failure times and weight loss scales, which is applied in the direction of program control, instruments, control/regulation systems in sequence/logic controllers, and can solve the problems of short service life, few functions, and unreasonable structure of equipment, and achieve equipment use The effect of long life, few overcoming functions, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

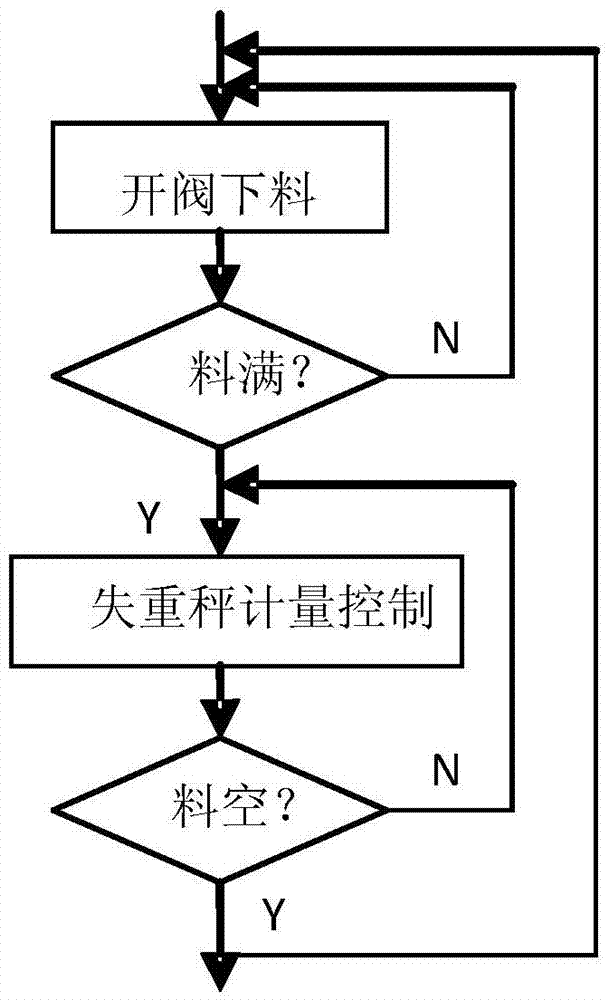

[0030] According to an embodiment of the present invention, such as figure 1 As shown, a method for reducing the number of failures of the fly ash weight loss scale is provided.

[0031] The technical scheme of the invention reduces the failure frequency of the fly ash weight loss scale of a branch factory. The failure frequency of cement production metering equipment is less than 3 times / month.

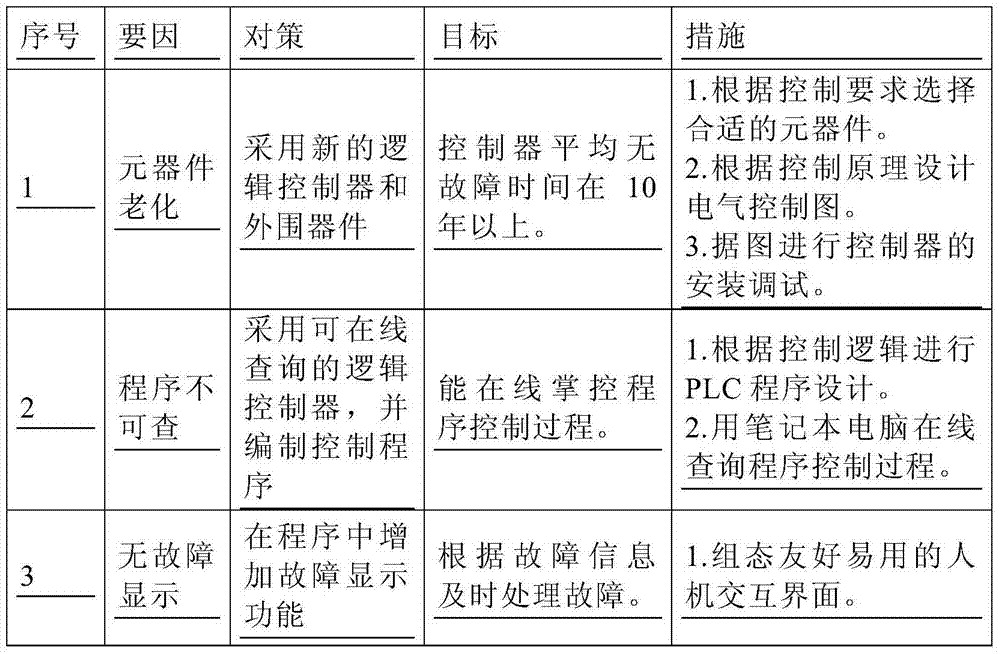

[0032] Countermeasures for formulating the technical solution of the present invention:

[0033] Tabulation: Peng Sansu Date: 2013.7.19

[0034]

[0035] The countermeasures of the technical solution of the present invention are implemented:

[0036] Implementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com