A 3D printer control system with nozzle temperature compensation

A 3D printer and control system technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of unfavorable promotion, high cost of printer cover and cover control, and achieve quality assurance and machine average trouble-free time, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

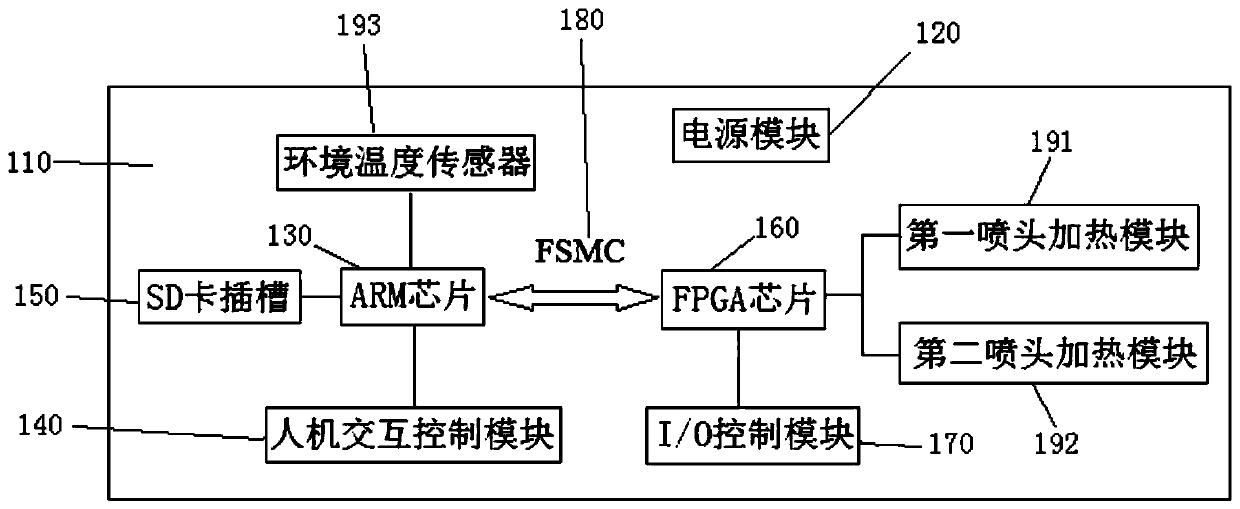

[0024] Such as figure 1 As shown, the present invention provides a temperature-compensable 3D printer control system, including a circuit substrate 110, on which a power module 120 is provided for powering the entire control system.

[0025] An upper layer control module and a lower layer control module are provided on the circuit substrate 110 .

[0026] Wherein, the upper control module includes an ARM chip 130 , a human-computer interaction module 140 , an SD card slot 150 and an ambient temperature sensor 193 .

[0027] The lower layer control module includes the FPGA chip 160 , the I / O control module 170 , the I / O of the motor servo, and the first shower head heating module 191 and the second shower head heating module 192 .

[0028] The circuit substrate 110 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com