Automatic mechanical top sizing block mechanism of double-layer flat vulcanizing machine

An automatic machine, double-layer plate technology, applied in the field of top bolster iron mechanism, can solve the problems of difficult to ensure product vulcanization quality, high labor intensity of operators, difficult to realize automatic control, etc., so as to avoid the influence of human factors and reduce labor intensity. , to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

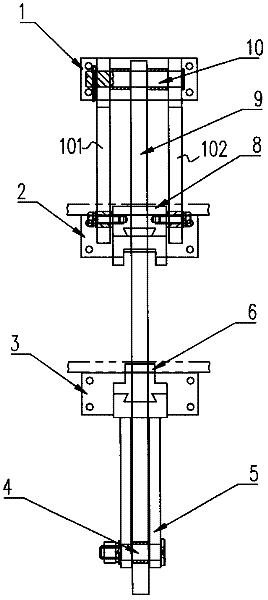

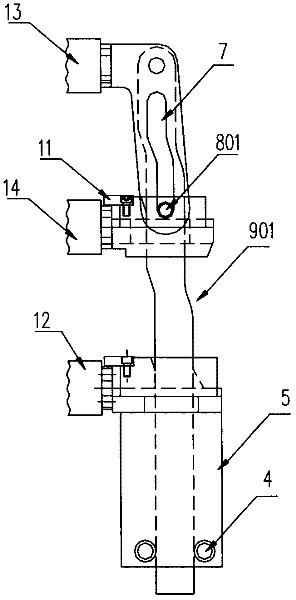

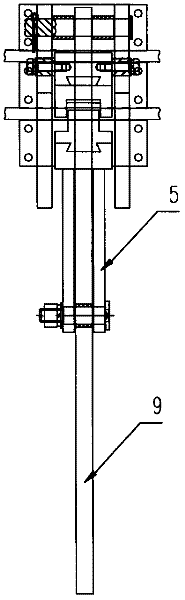

[0016] See figure 1 versus figure 2 , A double-layer plate vulcanizing machine automatic mechanical top pad iron mechanism, comprising: a stop 11, an upper connecting seat fixedly connected to the upper hot plate 13 of the vulcanizing machine 1, a middle connecting seat 2 fixedly connected to the middle hot plate 14 of the vulcanizing machine The lower connecting seat 3 and the vertical guide rod 9 are fixedly connected with the lower hot plate 12 of the vulcanizer. The upper end of the vertical guide rod 9 is fixed on the upper connecting seat 1 through the pin 10, the upper slide 8 and the lower slide 6 are arranged on the vertical guide rod 9, and the upper slide 8 is fixedly connected to the middle connecting seat 2. The sliding block 6 is fixedly connected to the lower connecting seat 3. The upper connecting seat 1 is provided with two guide arms 101, 102 extending downward and symmetrically arranged on the basis of the vertical guide rod. Each guide arm is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com