Integrated control device for short-circuit self-cutoff of zero-point potential difference of electrolyzer

An integrated control and electrolytic cell technology, applied in electrolysis components, electrolysis process, etc., can solve problems such as zero-point potential difference fluctuation, false lighting, equipment signal interference, etc., achieve zero-point potential difference value stability, reduce fluctuation rate and shutdown rate , avoid the effect of high failure rate of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

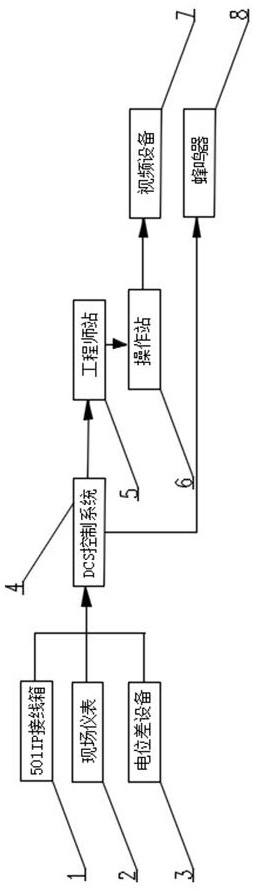

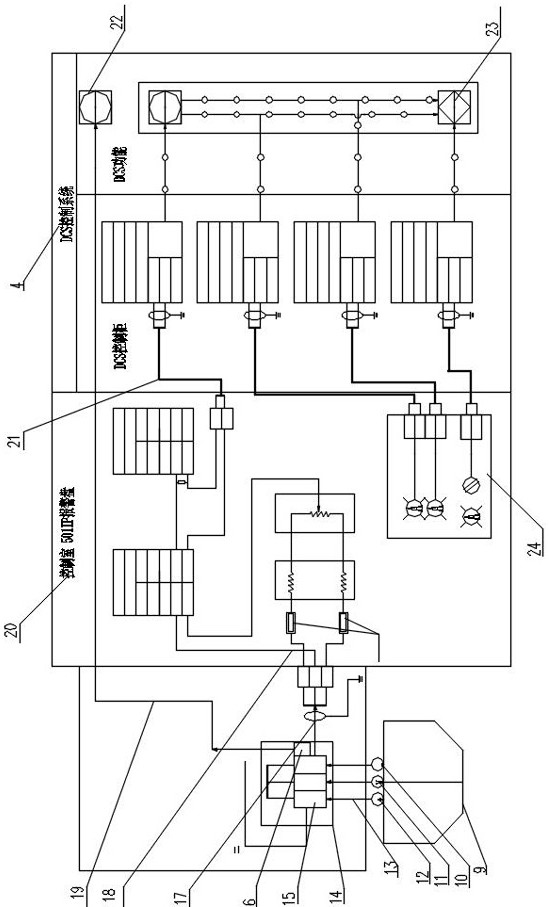

[0024] join figure 1 , figure 2 It can be seen that a kind of electrolytic cell zero point potential difference short circuit self-cutting integrated control device of the present invention consists of 501IP junction box 1, field instrument 2, potential difference equipment 3, engineer station 5, operation station 6, video equipment 7, buzzer 8 Composition: 501IP junction box 1, field instrument, potential difference device 3 are respectively connected with DCS control system 4, DCS control system 4 is electrically connected with engineer station 5, buzzer 8, engineer station 5 is electrically connected with video equipment through operation station 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com