Method for producing joints for transmitting rotary motion

A technology of rotary motion and connecting parts, applied in the direction of anti-centrifugal force rotating parts, engine components, applications, etc., can solve the problems of complex production of pivot pins, and achieve the effects of weight saving, great flexibility, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

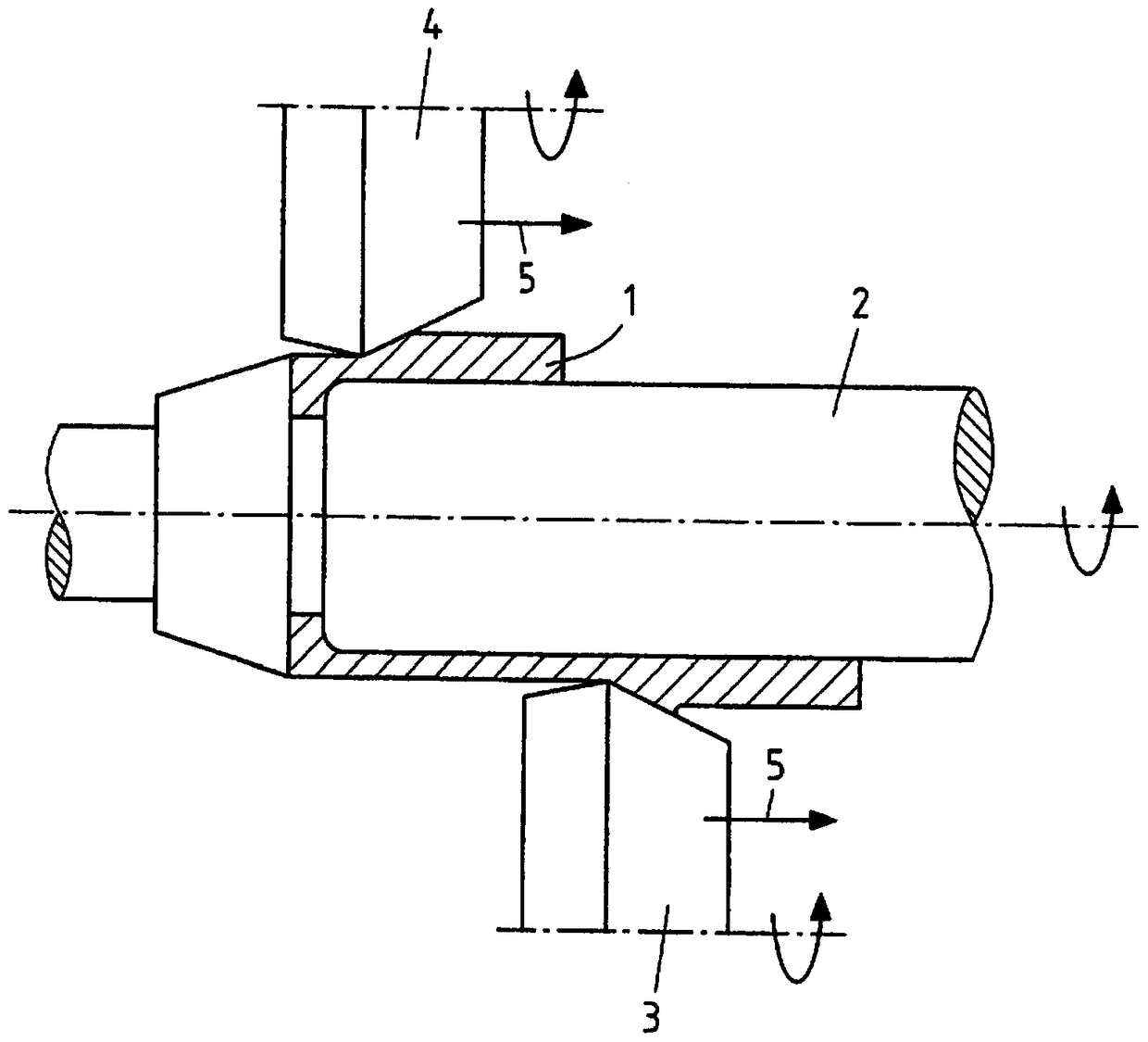

[0020] Now figure 1 In a schematic view, the sequence of fluid forming or fluid diversion of a tubular blank 1 is shown, which can be provided, for example, via discs or pipe sections. The inner mandrel 2 predetermines the shape on which identical rotating pressing tools 3 , 4 , only half shown in each case, press against the blank. Here the pressing tools 3 , 4 travel in the advancing direction 5 and are moved, for example to correspond to the contour of the mandrel 2 so that the blank 1 is deformed accordingly. On the basis of this production principle, any rotationally symmetrical shape, especially thickened and conical sections provided in a radial circumferential manner, figure 1 It is readily conceivable to produce the extrusion tools 3 , 4 shown. Any other shape can be produced in the blank by extrusion via an eccentrically rotating tool used instead of the extrusion tools 3 , 4 .

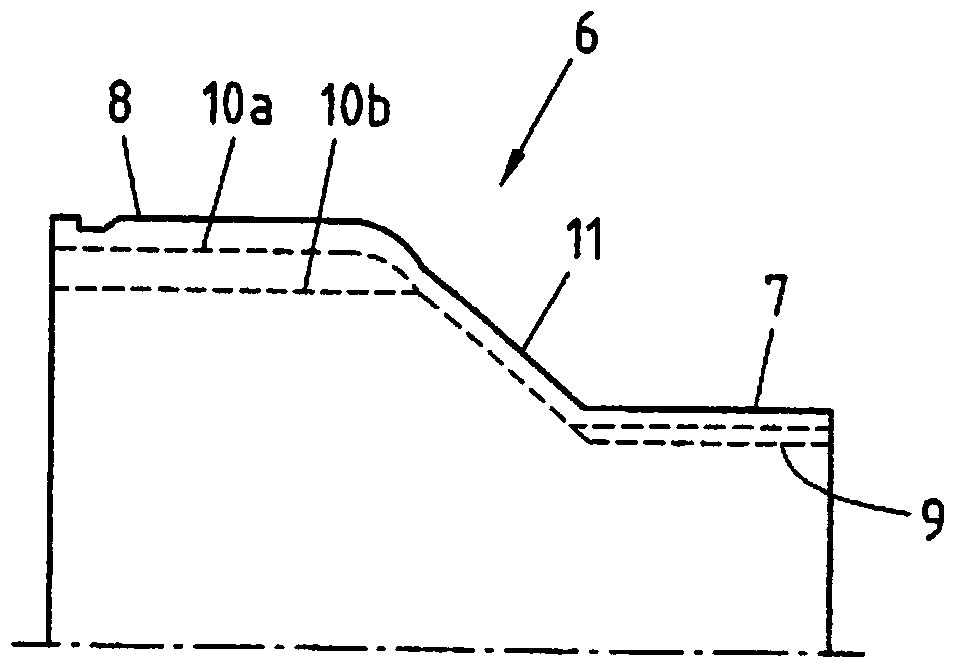

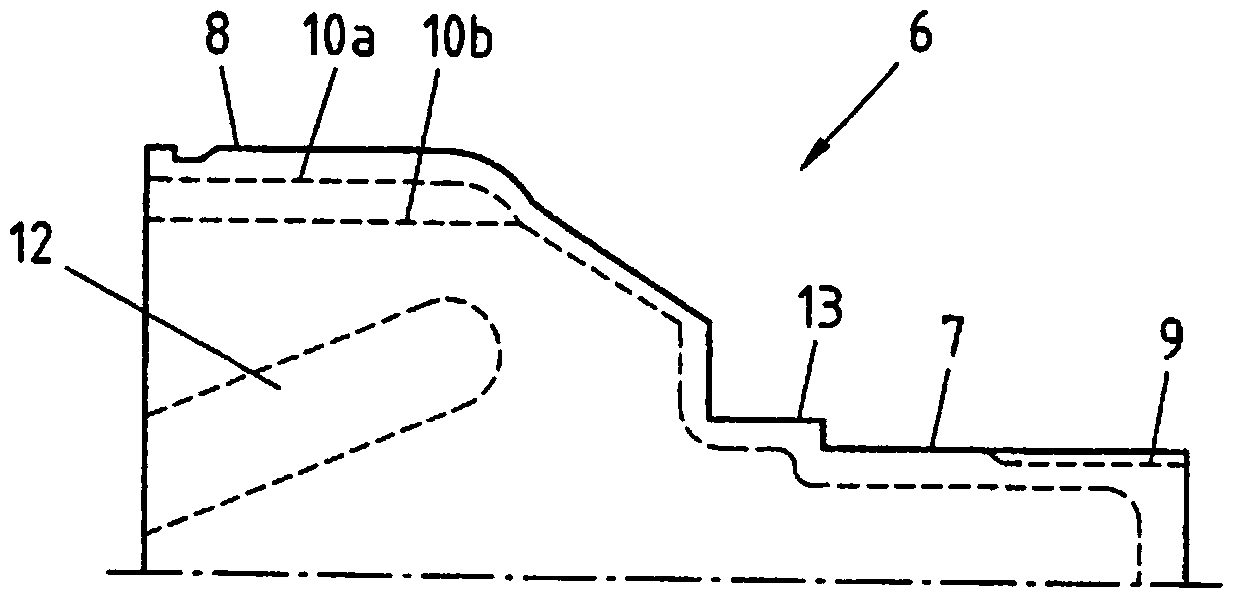

[0021] For example, figure 2 A first exemplary embodiment of a connection piece 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com