Processing method and device for internal thread

一种加工方法、加工装置的技术,应用在有螺纹的制品、其他家里用具、家里用具等方向,能够解决加工时间限制、无法进行高强度且高刚性的加工机的设计等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, the present invention will be described based on the embodiments shown in the drawings.

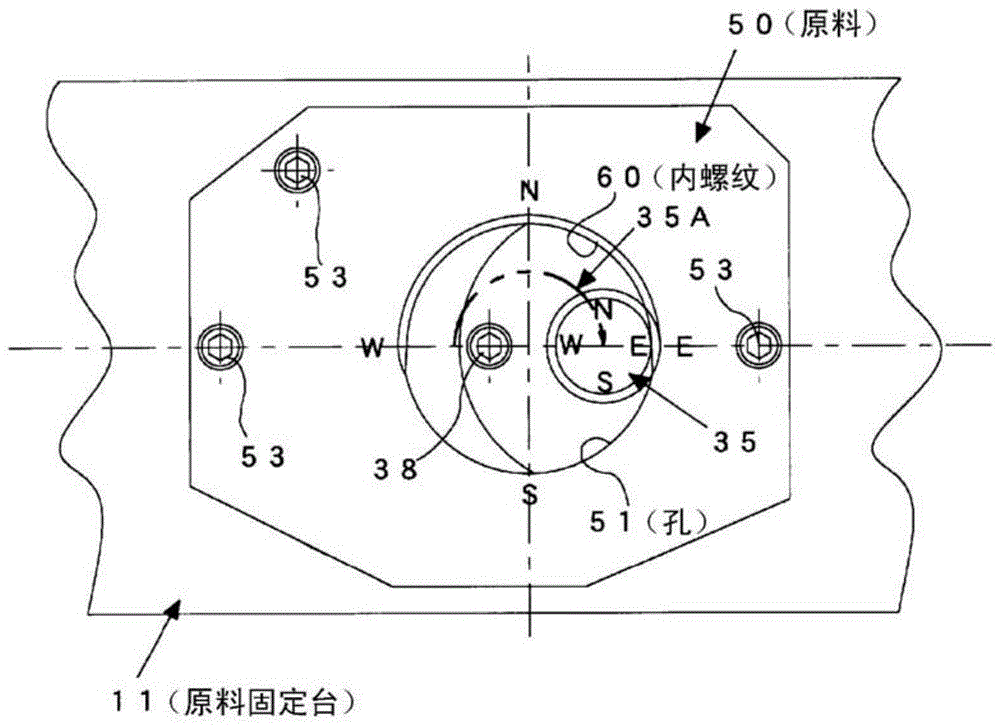

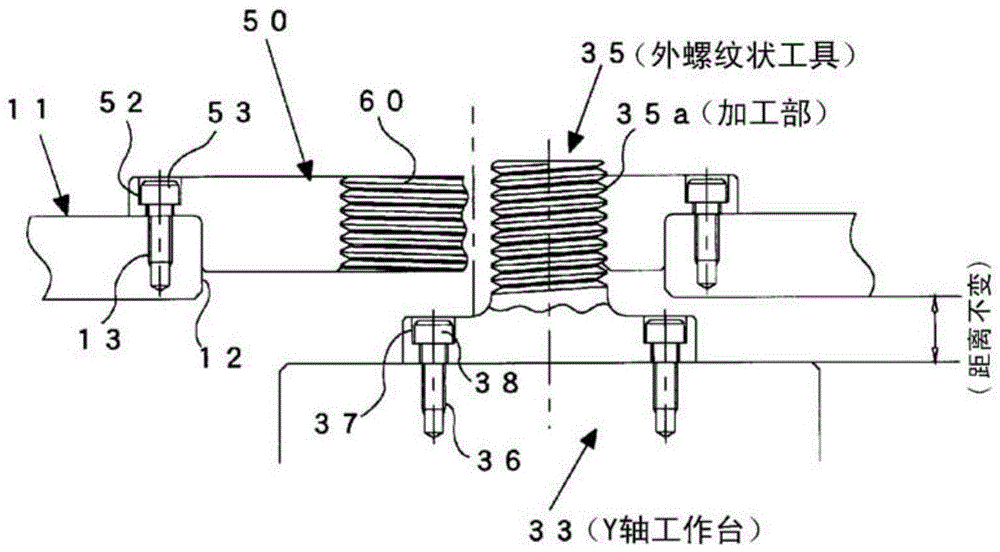

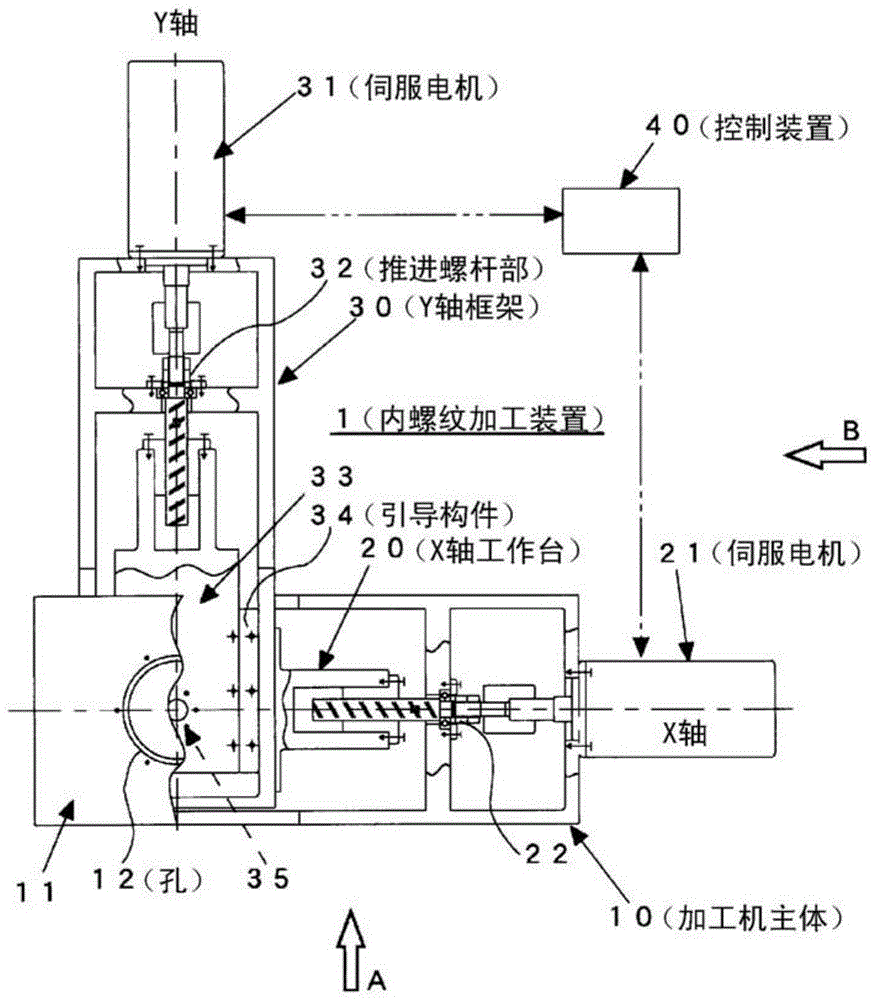

[0044] figure 1 In order to show the machining method of the internal thread 60 according to one embodiment of the present invention, figure 2 express figure 1 important part of. Figure 3-5 The internal thread processing apparatus 1 used for the processing method of the internal thread 60 which concerns on this embodiment is shown. In addition, in figure 2 Indicates only important parts.

[0045] The internal thread processing device 1 according to this embodiment includes: a processing machine main body 10; an X-axis table 20 mounted on the processing machine main body 10; and a Y-axis table 33 fixed to the X-axis table 20 so that the Y-axis frame 30 on X-axis table 20 .

[0046] The processing machine main body 10 is fixed to a table (not shown) of an appropriate height in consideration of a working height and the like.

[0047]On the upper surface of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com