Separation and enrichment determination method for Ir, Rh, Pt, Pd and Au in secondary resource material

A secondary resource material, separation and enrichment technology, applied in the direction of material stimulation analysis, thermal stimulation analysis, preparation of test samples, etc., can solve the problems of salt interference, acid-soluble insoluble, etc., the method is simple and easy, The effect of addressing demand gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

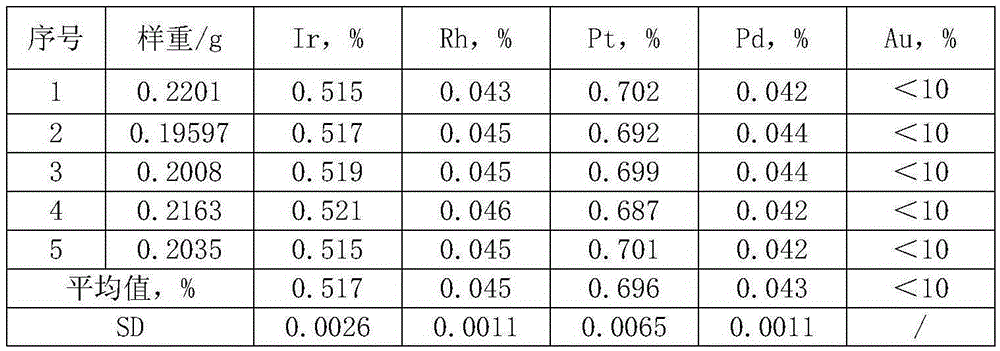

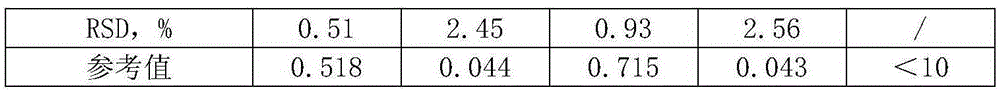

[0029] Simultaneous determination of low content Ir, Rh, Pt, Pd, Au in aqua regia insoluble slag

[0030] This kind of aqua regia insoluble slag is formed in the hydrometallurgical recycling process of precious metal secondary resource waste. Its composition is relatively complex, containing a large amount of Fe, Al, Si and a small amount of Pt, Mg, Rh, Pd, Ir, Ag, and the sample is homogenized by a disc mill before sampling and analysis. Weigh 5 portions of 0.2 g dried samples in parallel, put them into a 30 mL nickel crucible, place them in a muffle furnace, raise the temperature to 750°C and burn for 1 hour, then cool. Join Na 2 o 2 : NaCO 3 = 3: 1 mixed flux 3g, then covered with 3gNa 2 o 2 , put it into a muffle furnace and raise the temperature to 750°C for 20 minutes, take it out and cool it, put the nickel crucible into a 200mL beaker, heat water to leach the molten salt, and then neutralize it with hydrochloric acid until the solution is clear. Slowly add 5mL of...

Embodiment 2

[0036] Determination of Ir, Rh, Pt, Pd content in catalyst recovery waste residue.

[0037] This kind of catalyst recovery waste residue is acid-insoluble residue in the process of recycling automobile catalysts, petrochemical catalysts, etc., which contains a large amount of Al, Si and sodium salts. The sample was homogenized by a disc mill before sampling and analysis. Weigh 5 portions of 0.5 g dried samples in parallel, put them into a 30 mL nickel crucible, place them in a muffle furnace, raise the temperature to 750°C and burn for 1 hour, then cool. Join Na 2 o 2 : NaCO 3 = 3: 1 mixed flux 5g, then covered with 2gNa 2 o 2 , put it into a muffle furnace and raise the temperature to 750°C to melt for 25 minutes, take it out and cool it, put the nickel crucible into a 200mL beaker, heat water to leach the molten salt, and then neutralize it with hydrochloric acid until the solution is clear. Slowly add 2mL30% sodium chlorate solution and boil for about 45min. Adjust t...

Embodiment 3

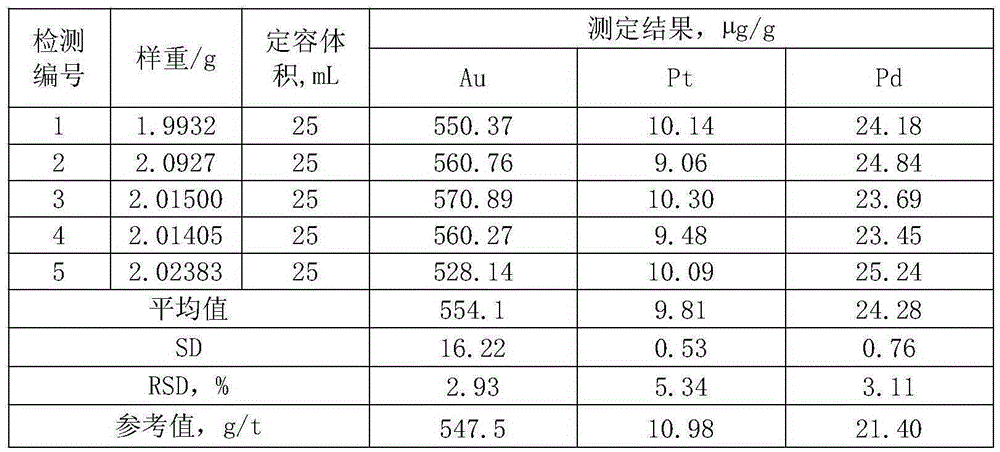

[0041] Determination of Pt, Pd, Au content in anode slime

[0042] Anode slime mainly contains a large amount of Cu, Pb, Sn, Sb, Mg, Bi, Ag, Al, Ni, Si, S, P and other elements, and also contains a small amount of precious metals. However, there are serious interferences in direct determination of extremely low content of Pt, Pd, and Au. Generally, lead fire assay is used to enrich Pt, Pd and Au to separate other interfering components for determination. However, the three elements of Pt, Pd, and Au need to be enriched and measured in two batches, so the operation is cumbersome and time-consuming.

[0043] Five samples of 2.00 g were weighed in parallel, put into a nickel crucible with a volume of 30 mL, placed in a muffle furnace, heated to 750° C. for igniting and kept for 1 h, and cooled. Join Na 2 o 2 : NaCO 3 = 3: 1 mixed flux 6g, then covered with 2gNa 2 o 2 , put it into a muffle furnace and raise the temperature to 750°C for 20 minutes, take it out and cool it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com