Efficient methane and carbon dioxide reforming Ni/SiO2 catalyst and electrostatic spinning preparation method

A carbon dioxide and catalyst technology, applied in the field of high-efficiency catalysts, can solve the problems that electrospinning technology has not been widely reported, and achieve the effects of simple operation, high catalytic activity and good anti-carbon deposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

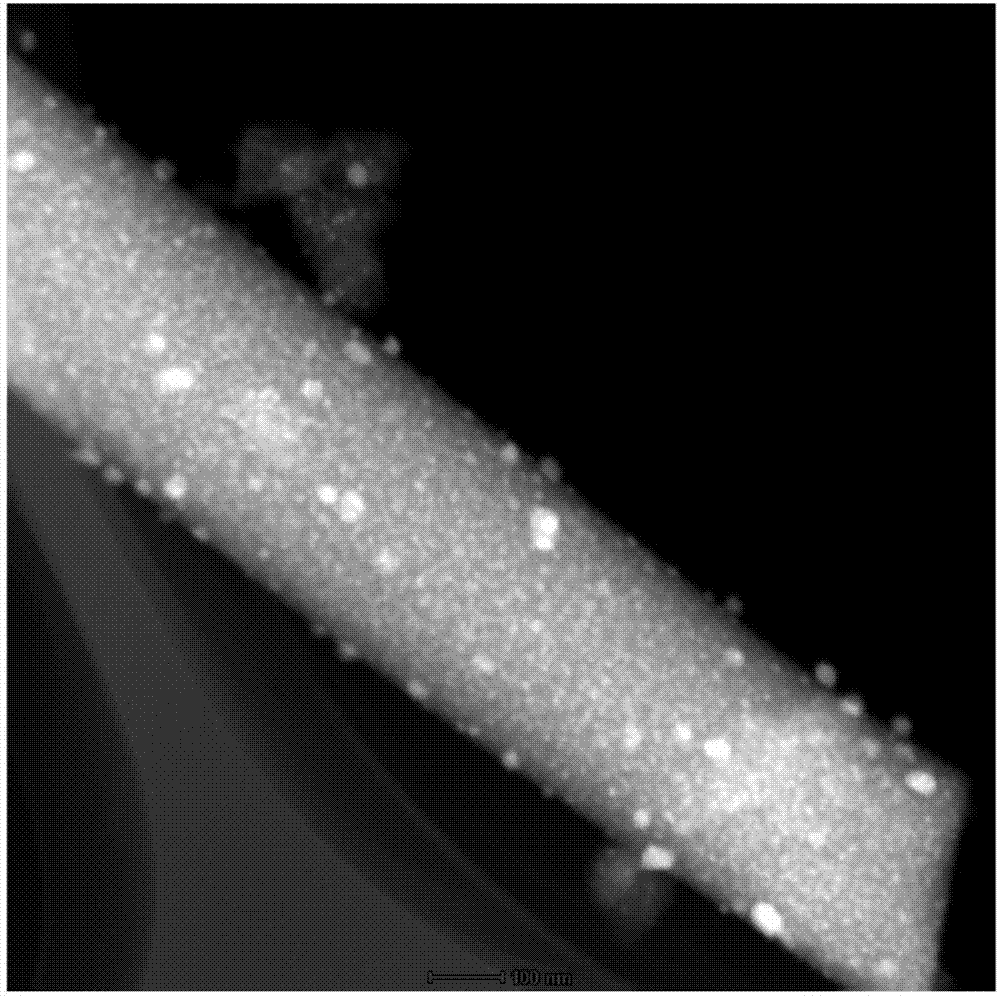

Image

Examples

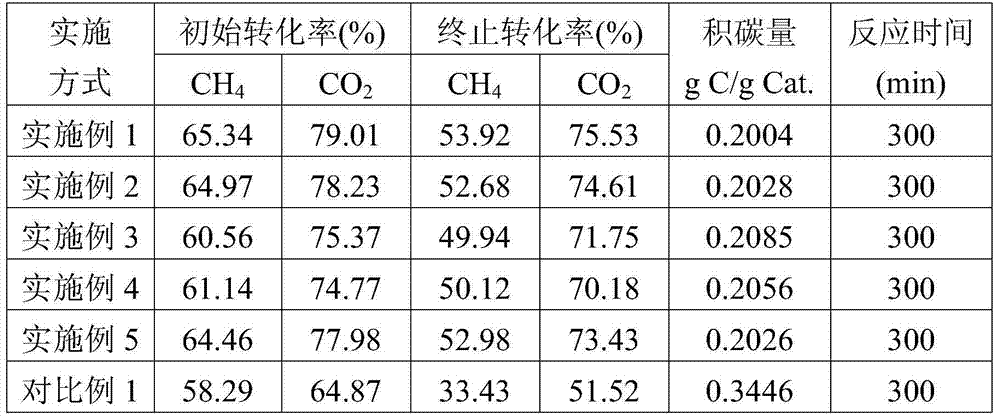

Embodiment 1

[0023] 1. Weigh 4.7g tetraethyl orthosilicate (TEOS) and 1.1g polyvinylpyrrolidone (PVP) and 1.13g nickel nitrate respectively, then dissolve TEOS in 0.95g dilute hydrochloric acid (substance concentration 0.080mol / L) and 1.25g In ethanol, PVP is dissolved in 4.12g N,N-dimethylformamide (DMF) and 2.50g dimethyl sulfoxide (DMSO), and nickel nitrate is dissolved in 1.82g ethanol; The three solutions were placed on a magnetic stirrer and stirred at a constant speed for 9 hours, and finally the three solutions were fully mixed and placed on a magnetic stirrer to stir for 0.5 hours to obtain a spinning precursor. Operations were performed at 25°C.

[0024] 2. Put the mixed liquid obtained in 1 into the syringe, then put the syringe into the push device, stick a layer of metal foil on the receiver, and the speed is 80r / min. The voltage was adjusted to 12kV, the spinning liquid feeding rate was 1ml / h, and the spinning was started.

[0025] 3. Dry the sample obtained in 2 at 120°C f...

Embodiment 2

[0028] 1. Nickel nitrate was dissolved in 1.82g of water; others were consistent with step 1 in Example 1.

[0029] 2. Same as Step 2 of Example 1.

[0030]3. Same as Step 3 of Example 1.

[0031] 4. Take 0.1g of the sample obtained in step 3 and place it in a quartz tube. After reduction at 600°C, react with methane, carbon dioxide and argon at a flow ratio of 1:1:2 at a temperature of 700°C. The catalyst evaluation results are shown in the table 1. CH 4 , CO 2 The highest conversion rates were 64.97%, 78.23%; H 2 The highest selectivities of , CO are 89.98%, 96.28%, respectively.

Embodiment 3

[0033] 1. TEOS was dissolved in 0.85g dilute nitric acid (substance concentration 0.080mol / L) and 1.25g ethanol; others were consistent with step 1 in Example 1.

[0034] 2. Same as Step 2 of Example 1.

[0035] 3. Same as Step 3 of Example 1.

[0036] 4. Take 0.1g of the sample obtained in step 3 and place it in a quartz tube. After reduction at 600°C, react with methane, carbon dioxide and argon at a flow ratio of 1:1:2 at a temperature of 700°C. The catalyst evaluation results are shown in the table 1. CH 4 , CO 2 The highest conversion rates were 60.56%, 75.37%; H 2 The highest selectivities of , CO are 87.32%, 95.42%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com