Cam driving type compressing clamp for shaft workpieces

A shaft-type workpiece and driving technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of high labor intensity for operators, failure to complete automatically, and low degree of automation, so as to facilitate popularization, use, and production The effect of low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

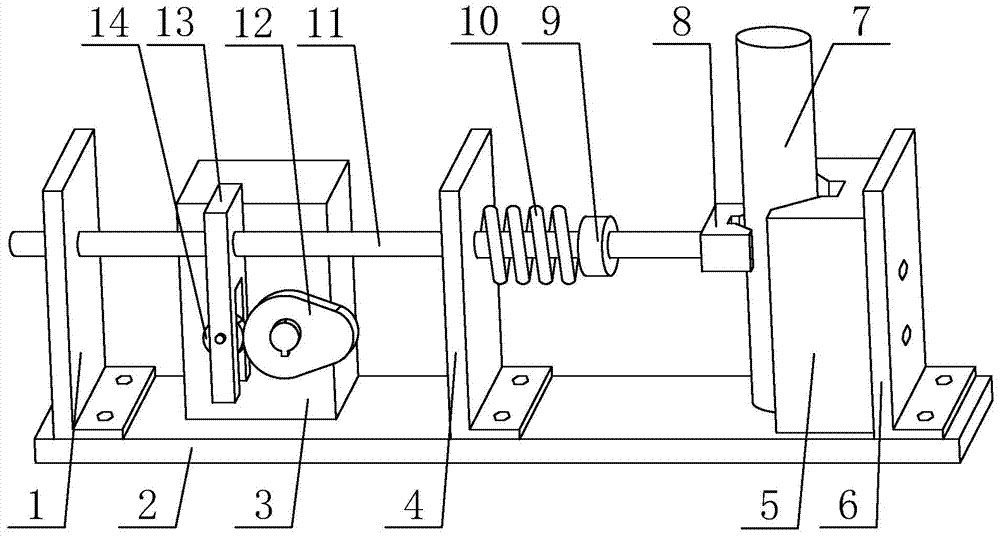

[0021] Such as figure 1 A cam-driven shaft workpiece pressing fixture shown includes a base plate 2, a power box 3 fixedly installed on the upper side of the base plate 2, and a power box 3 fixedly installed on the upper side of one end of the base plate 2 through an L-shaped baffle plate 6. The V-shaped pad 5 and the V-shaped pressing head 8 that is used to compress the workpiece 7 in cooperation with the V-shaped pad 5 are characterized in that: it also includes a fixed installation on the power output shaft of the power box 3 for driving The cam 12 that the push rod 11 moves back and forth in the horizontal direction; the upper side of the bottom plate 2 is slidingly installed with the push rod 11 through the L-shaped support plate 1 and the L-shaped support plate 2 4 parallel to each other, and the middle part of the push rod 11 is fixedly installed There is a roller frame 13, the roller frame 13 is provided with a roller 14 used in conjunction with the cam 12, the V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com