bicycle hub device

A bicycle and flower hub technology, applied in the field of bicycle hub devices, can solve the problems of flywheels, freewheels, tower bases, insufficient strength of aluminum, easy deformation, etc., and achieve the effects of widening the design space, reducing weight and increasing speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

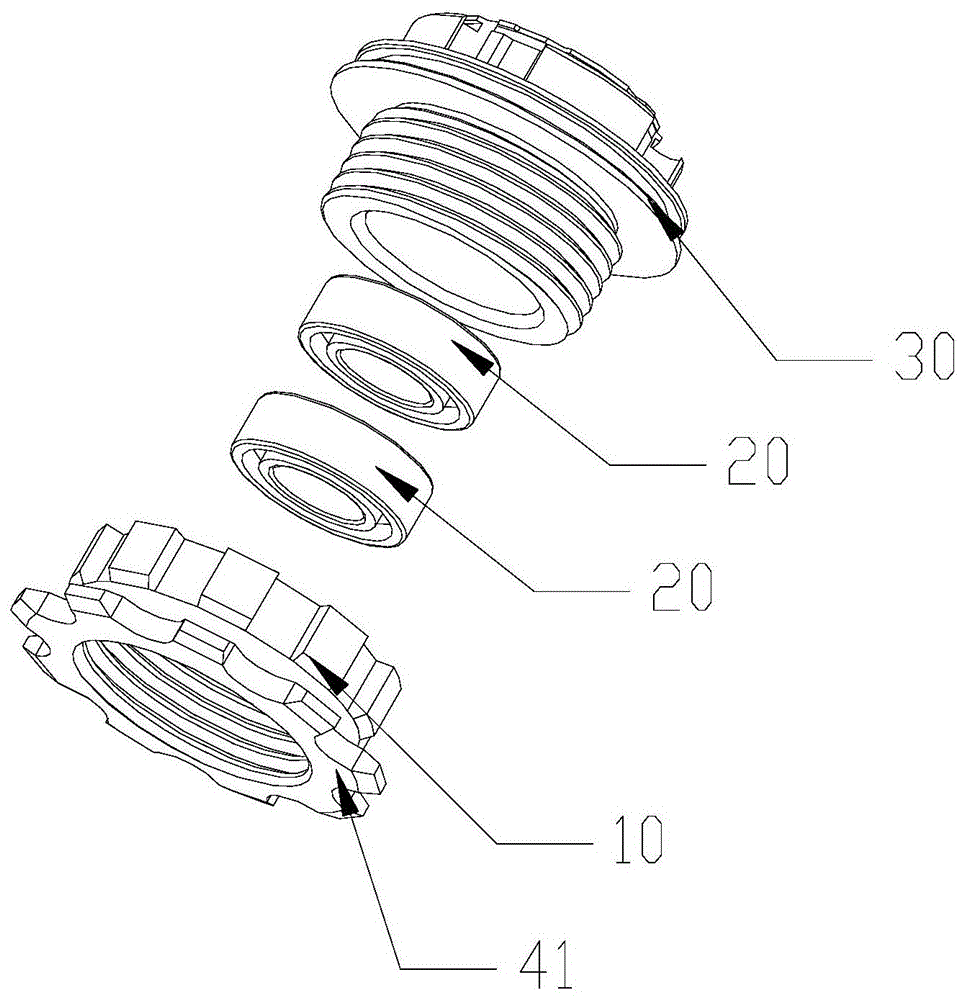

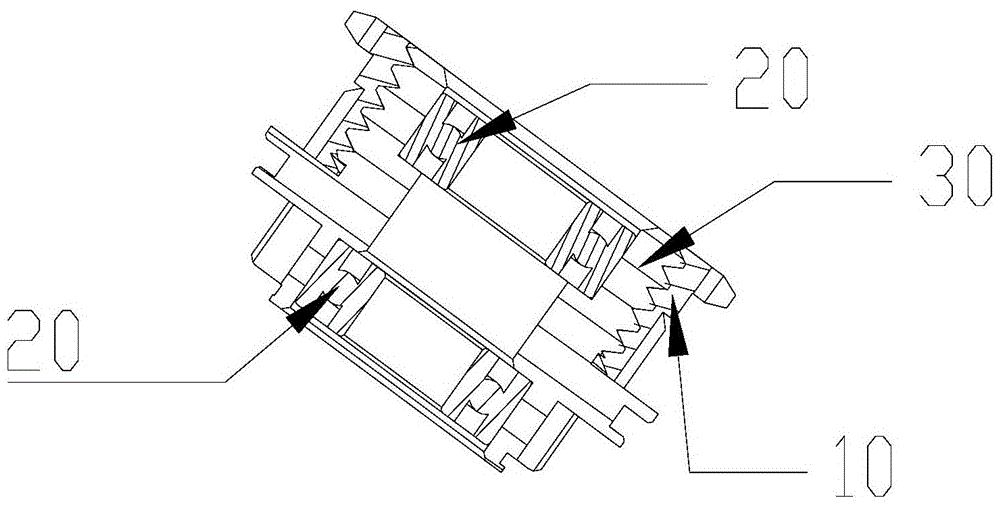

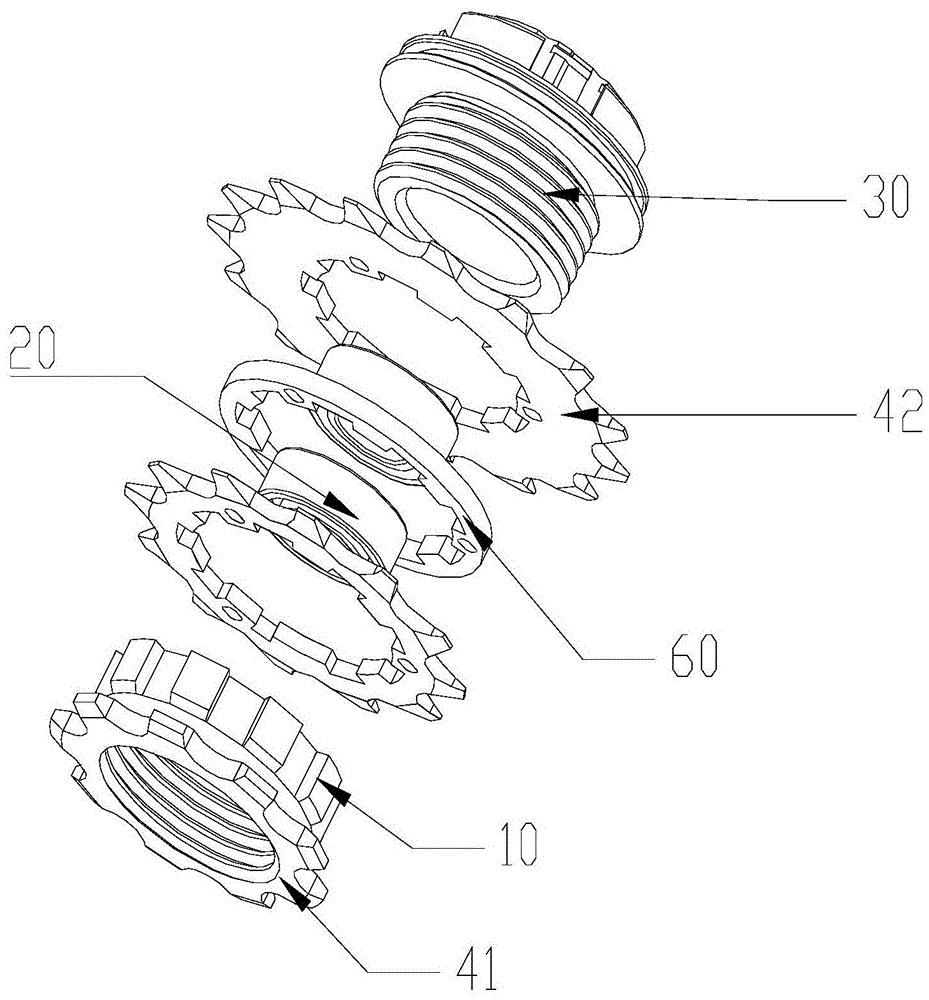

[0027] See Figure 1 to Figure 6 , The present invention relates to a bicycle hub device, and its preferred embodiment includes a freewheel body 10, a bearing 20, a shaft sleeve 30 and a flywheel set.

[0028] The tower base 10 is hollow and has openings at both ends, and the shaft sleeve 30 is hollow and has openings at both ends. The shaft sleeve 30 is coaxially sleeved outside the bearing 20 , and the tower base 10 is detachably coaxially sleeved on the shaft sleeve 30. Outside, flywheel group is located at outside tower base 10.

[0029] In this way, the freewheel body 10 and the bushing 30 adopt a detachable installation design, which is convenient for assembly and maintenance, and widens the design space of the hub.

[0030] Preferably, the body base 10 is connected to the shaft sleeve 30 through threads. Specifically, the inner peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com