sewing system

A technology of a control unit and a sewing machine, which is applied in the field of sewing systems, and can solve the problems of inability to perform simultaneous and efficient sewing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

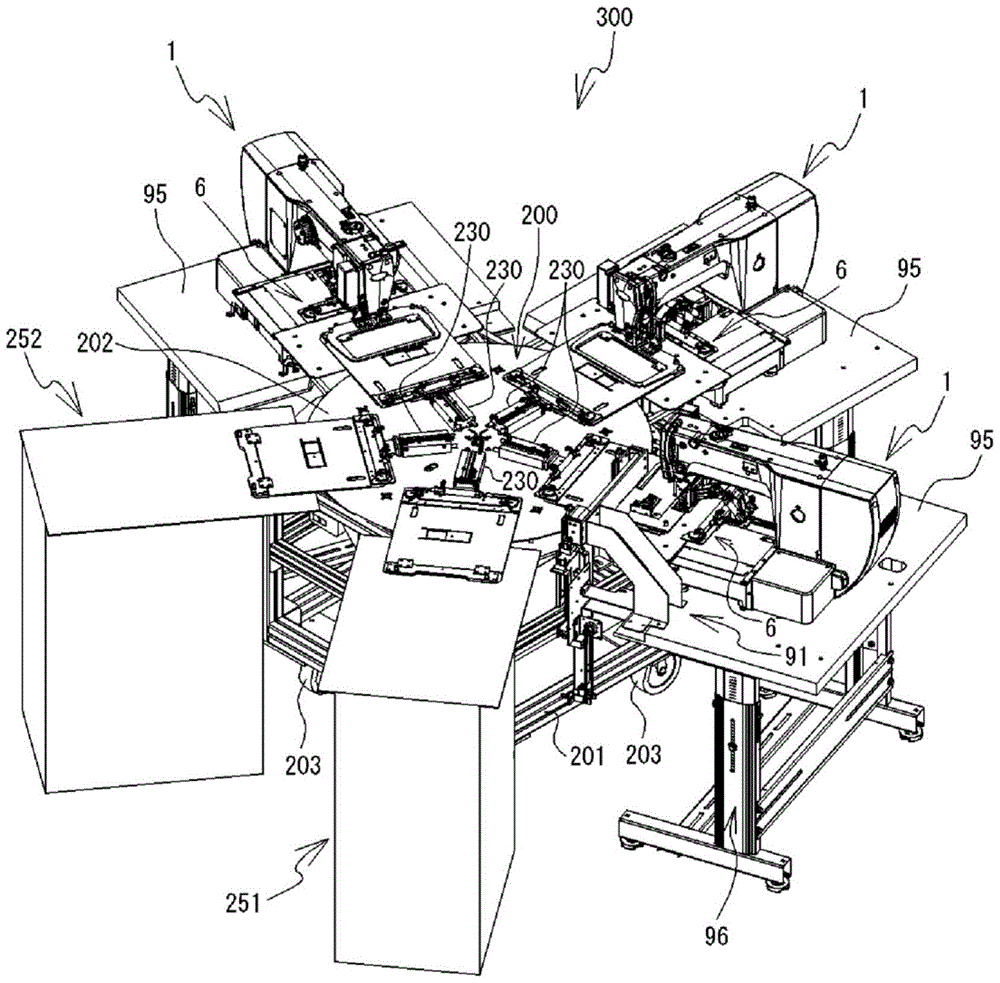

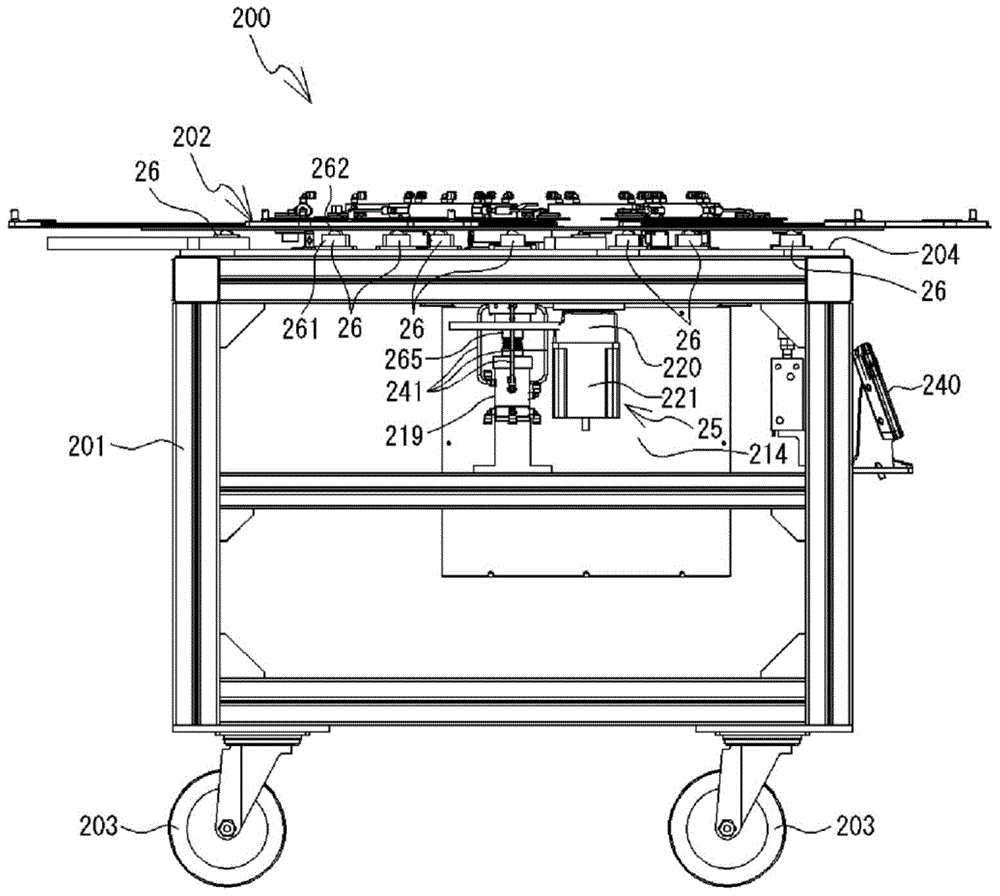

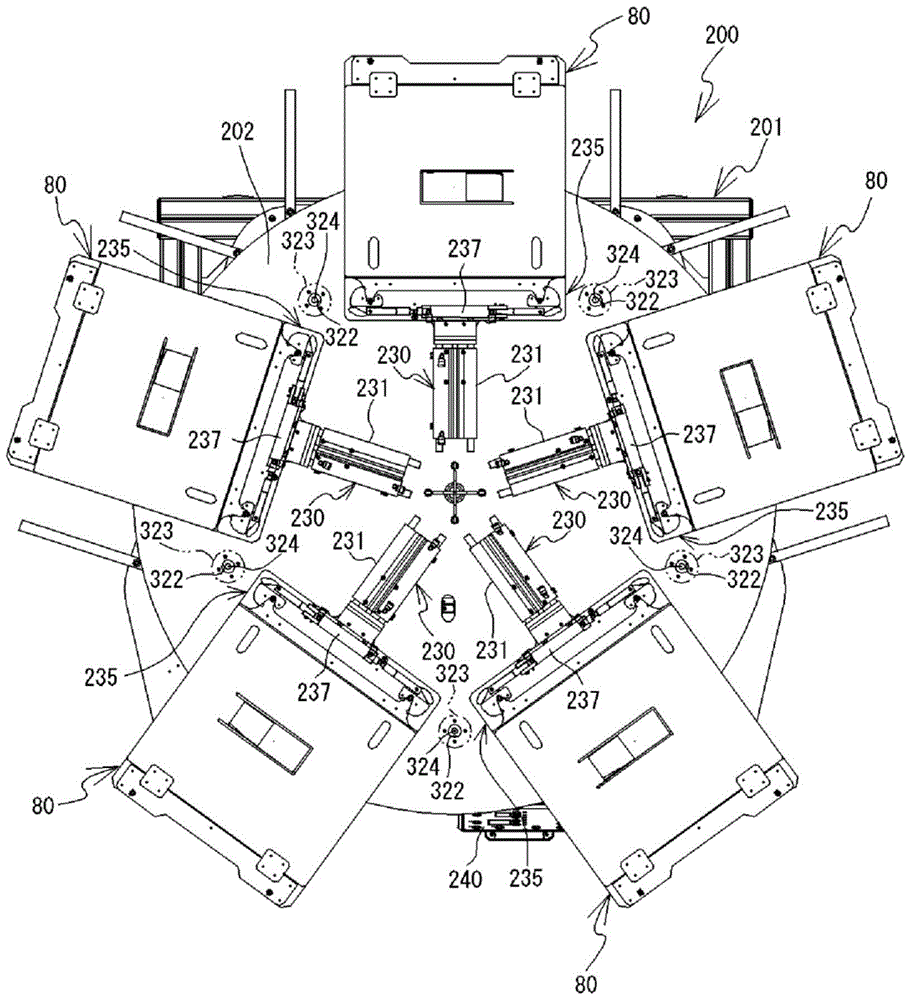

[0036] A first embodiment of the present invention will be described with reference to the drawings. refer to Figure 1 ~ Figure 4 A schematic configuration of the sewing system 300 including the sewing machine 1 will be described. Figure 4 The left oblique lower side, the right oblique upper side, the left oblique upper side, and the right oblique lower side are the front side, the rear side, the left side, and the right side of the sewing machine 1 included in the sewing system 300 . In the following description, left and right, front and rear, and up and down indicated by arrows in the figure are used. The sewing system 300 is arranged with a plurality of (three in this embodiment) sewing machines 1 and two consoles 251 and 252 at equal intervals around the holding board supply device 200, and the plurality of sewing machines 1 and the two consoles 251 and 252 are arranged radially in plan view around the holding plate supply device 200 . One sewing machine 1 among the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com