Centrifugal testing machine for inertial control devices

An inertial control and centrifugal test technology, which is applied in the centrifugal test field of inertial control devices, can solve problems such as high precision of centrifugal acceleration, difficulty in meeting test requirements, large changes in centrifugal acceleration, etc., to meet the requirements of precision acceleration environmental tests, Easy to promote and use, full-featured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

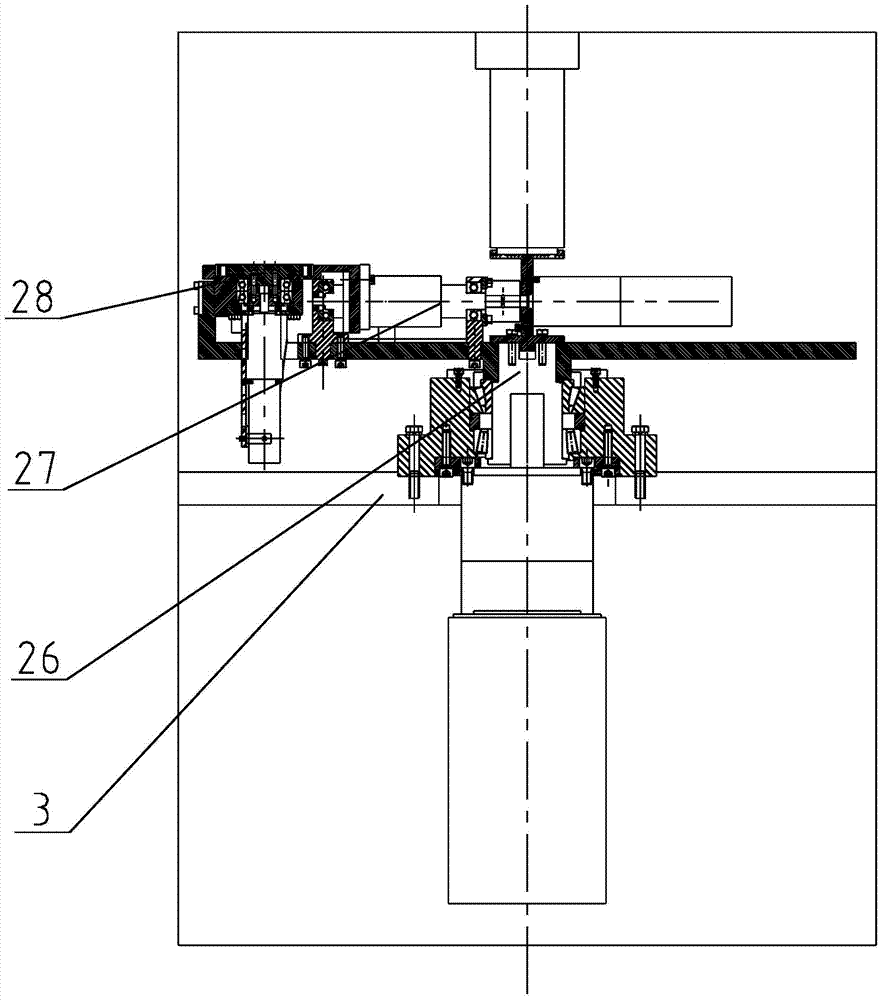

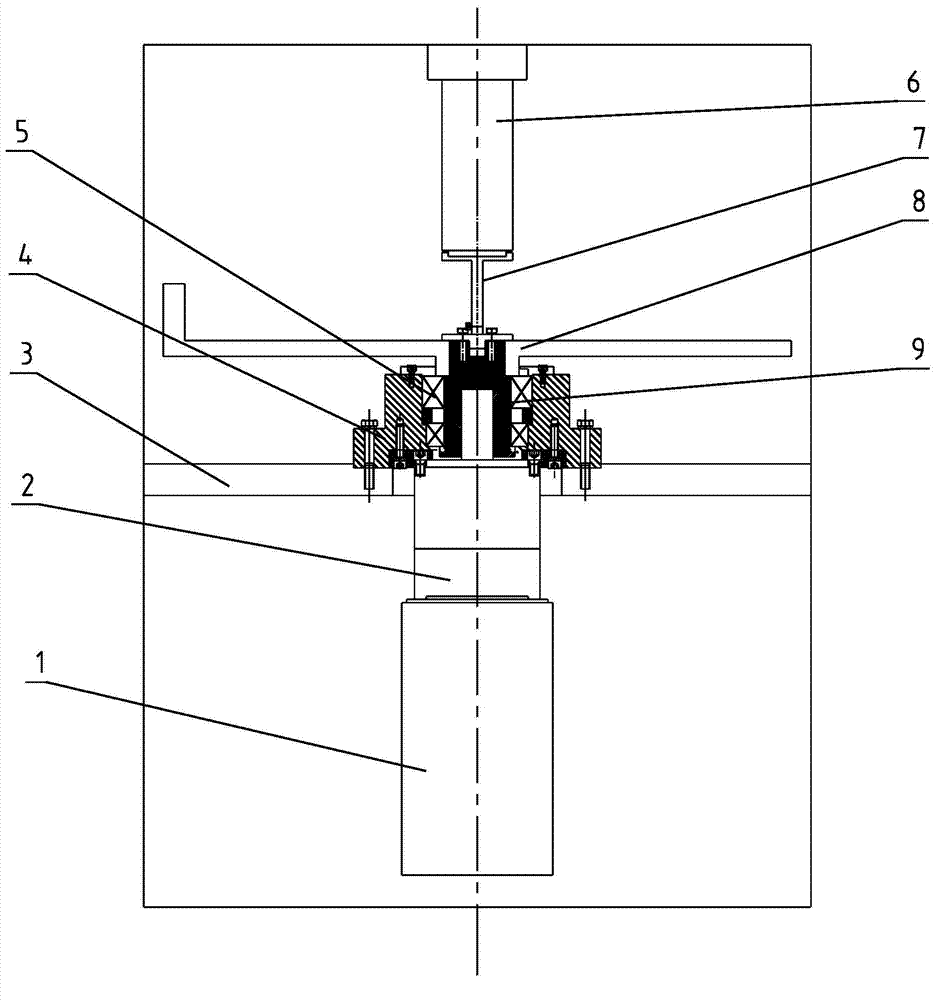

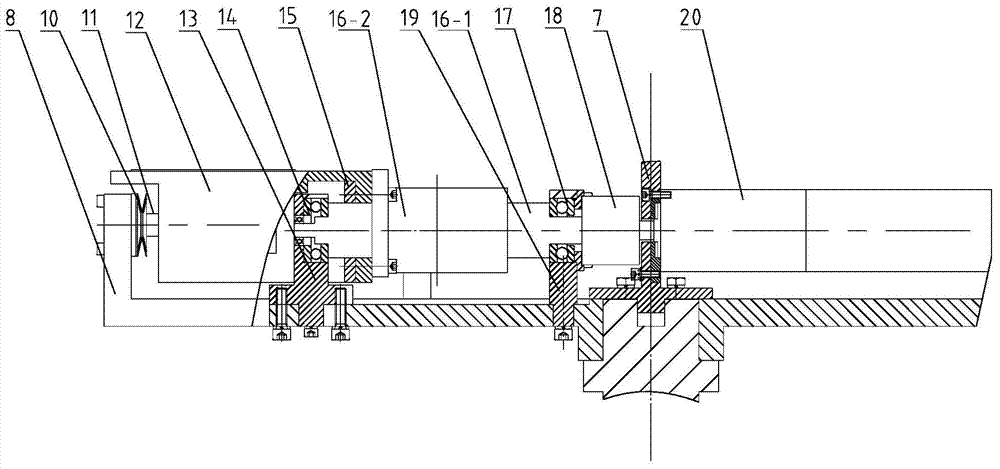

[0030] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a frame 3, a centrifugal acceleration generating mechanism 26, a centrifugal acceleration radius adjusting mechanism 27 and an inertial control device angle adjusting mechanism 28, and the centrifugal acceleration generating mechanism 26 includes a bearing seat 4 fixedly connected to the top of the frame 3 And the bearing 5 that is fixedly connected on the bearing seat 4, the main shaft 9 is supported and installed on the bearing 5, the centrifugal acceleration generating motor 1 and the centrifugal acceleration generating mechanism 26 power source as the centrifugal acceleration generating mechanism 26 power source are arranged below the frame 3 Generate a reducer 2 connected to the motor 1, the main shaft 9 is connected to the output shaft of the reducer 2, the top of the main shaft 9 is fixedly connected with a rotating arm 8, and the top of the rotating arm 8 is fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap