Integrated rotor air path structure of high-power motor

An integral rotor, high-power technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., can solve the problems of easily damaged winding insulation performance, reduce winding electric density, etc., to reduce winding electric density, reduce The degree of insulation and the effect of reducing ventilation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

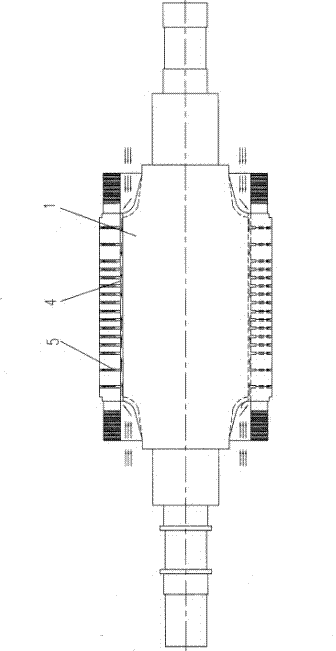

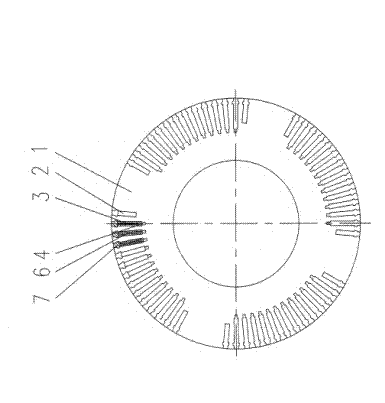

[0011] A high-power motor integral rotor wind path structure, comprising an integral rotor core 1, on which the integral rotor core 1 is respectively provided with a ventilation groove 2 and a winding inlay groove 3, and at the bottom of the winding inlay groove 3 is provided with a winding inlay groove bottom The ventilation groove 4 is provided with semi-conical radial air passages 5 at intervals on both inner walls of the winding mosaic groove 3, and the bottom end of the semi-conical radial air passage 5 communicates with the ventilation groove 4 at the bottom of the winding mosaic groove. A winding 6 is arranged in the winding embedding groove 3 , and a slot wedge 7 is arranged on the top of the winding embedding groove 3 .

[0012] The number of semi-conical radial ventilation passages 5 arranged at intervals on the inner sidewall of the middle part of the winding embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com