Manufacturing method of line card type printed circuit board with super large size and high alignment of layers

A printed circuit board, ultra-large size technology, applied in the field of printed circuit board production, can solve the problems of poor hole position accuracy and poor alignment between layers, and achieve the effect of improving alignment between layers

Active Publication Date: 2018-01-09

WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

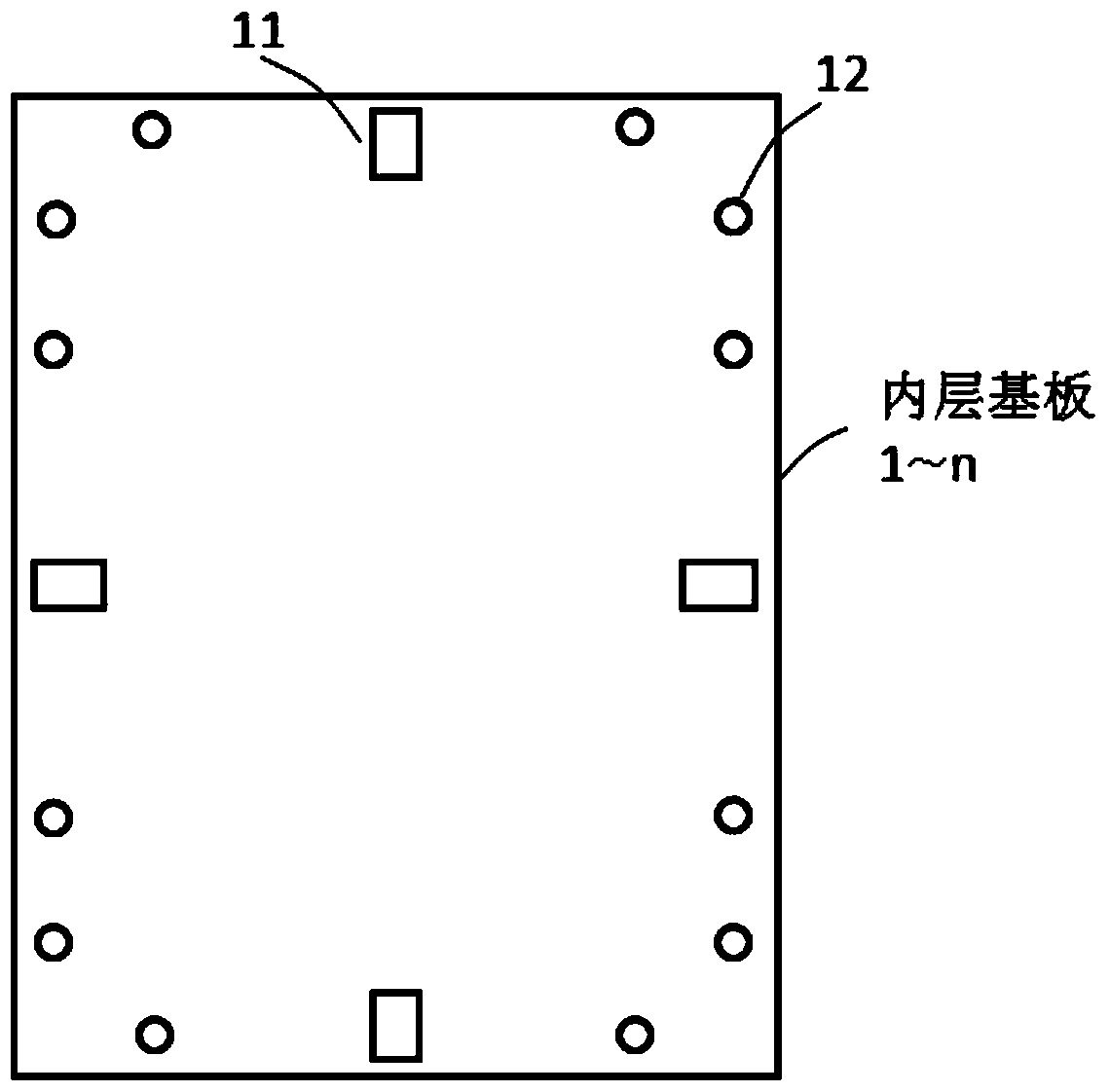

[0003] In order to solve the problems of layer-to-layer alignment and hole position accuracy during the processing of high-layer, super-large-size and high-alignment line card printed circuit boards, the present invention uses 4 square holes combined with 12 circular positioning holes for simultaneous positioning. Cooperating with CCD automatic drilling machine to drill holes, it overcomes the problems of poor alignment between layers and poor hole position accuracy, and successfully develops a production method for line card printed circuit boards with super large number of layers and high alignment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

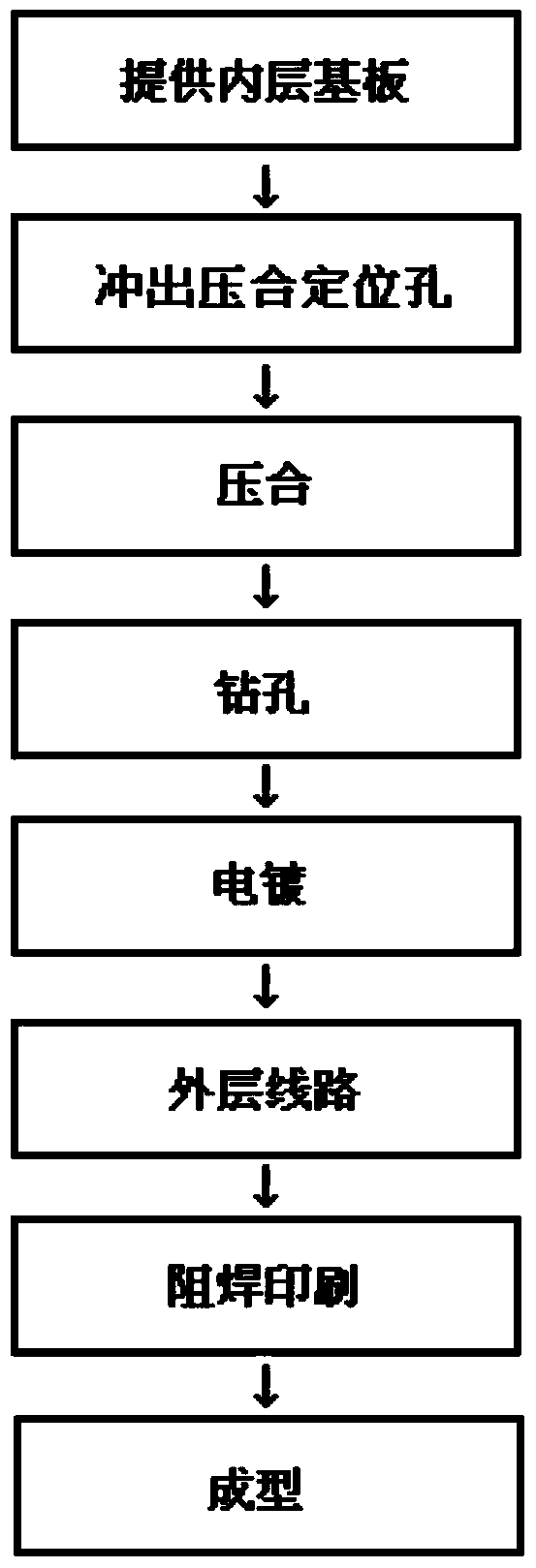

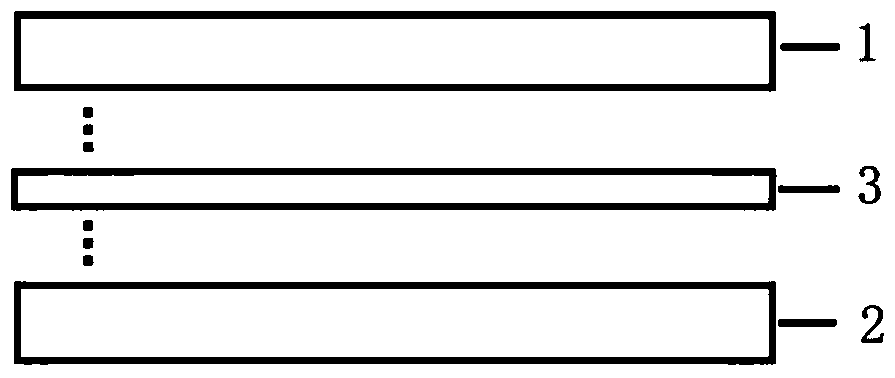

The invention belongs to the field of manufacturing process of printed circuit boards and particularly discloses a manufacturing method of ultralarge line-card type printed circuit boards with large layer number and high alignment degree. The manufacturing method includes steps of (1) providing an inner substrate; (2) punching pressed positioning holes; (3) pressing; (4) drilling holes; (5) electroplating; (6) paving outer liners; (7) printing in solder resist; (8) forming. The manufacturing method solves the problems of poor interlayer alignment and low accuracy of hole sites and patterns of finished products of the ultralarge line-card type printed circuit boards with high alignment degree and successfully develops ultralarge line card type products with large layer numbers and high alignment degree. The manufacturing method is simple and feasible, interlayer alignment and hole site accuracy of the ultralarge line-card type printed circuit boards with large layer number and high alignment degree can be greatly improved, and product demands are met.

Description

technical field [0001] The invention relates to a method for manufacturing a printed circuit board, in particular to a method for manufacturing a line card type printed circuit board with a super large number of layers and high alignment, and belongs to the field of printed circuit board manufacturing. Background technique [0002] At present, it is difficult to process large-size (610mm*912mm) high-alignment (5mil) line card printed circuit boards with more than 16 layers in the PCB industry. Before the successful development of this product, there is no simultaneous layer size of 610mm*912mm in the industry. Line card printed circuit boards that require less than 5mil alignment between layers. This type of product has serious problems in alignment between layers and drilling accuracy, especially the requirement of 5mil alignment between layers cannot be fully realized. General lines in the industry The interlayer alignment of card products is usually controlled at 6mil, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05K3/46

CPCH05K3/4611H05K3/4638H05K2203/0214

Inventor 徐友福杨志刚卫春

Owner WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com