Toothed belts and belt reduction gears provided with same

A reduction device, toothed belt technology, applied in transmission, transportation and packaging, components with teeth, etc., can solve the problems of increased noise, non-steering, tooth cutting, etc., to reduce noise and vibration, improve steering The effect of feeling

Active Publication Date: 2015-04-15

BANDO CHEM IND LTD

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this undesirable phenomenon can be eliminated to some extent by reducing the size of the teeth, on the other hand, the following new undesirable phenomenon may occur, that is, the strength of the teeth is reduced due to the reduction in the size of the teeth

If the strength of the teeth is reduced, when a large force is applied to the teeth, the teeth may be cut off, and the broken teeth may enter the pulley groove, causing the reduction mechanism to be locked, and then the steering cannot be turned.

For this reason, if the size of the belt teeth is reduced for the purpose of reducing the operating noise, the bandwidth has to be increased to ensure the strength of the teeth, resulting in an increase in the size of the reduction gear, and it becomes difficult to arrange the reduction gear in the vehicle body.

There is also the undesirable phenomenon that if the bandwidth is increased, the noise will increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0075] Next, the results of the noise test performed on the toothed belt will be described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

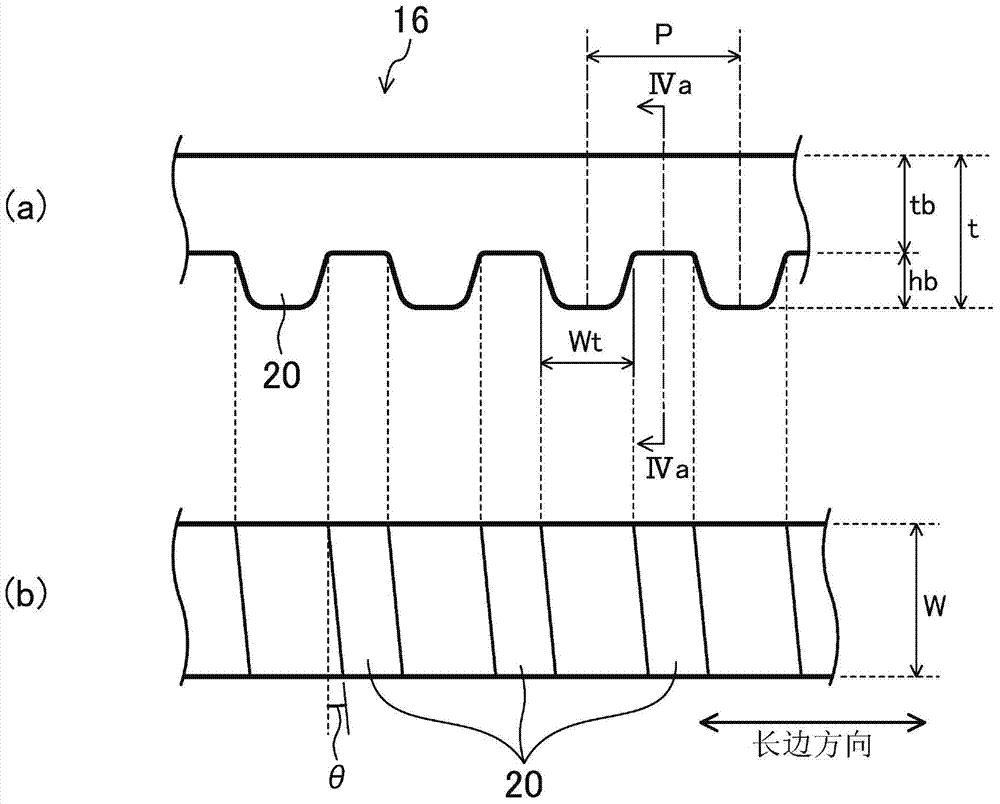

A toothed belt (16) comprises a back, and a plurality of helical teeth (2) disposed at a fixed pitch along the direction of the belt length and provided on the inner peripheral side of the back. An angle (theta), formed by the direction in which the tooth trace of a helical tooth extends and the belt width direction, is 7 to 10 degrees. When a ratio (A) is A = 100 x tb / hb, where tb is the back thickness and hb is the tooth height of the helical tooth (20), A is 120% to 240%.

Description

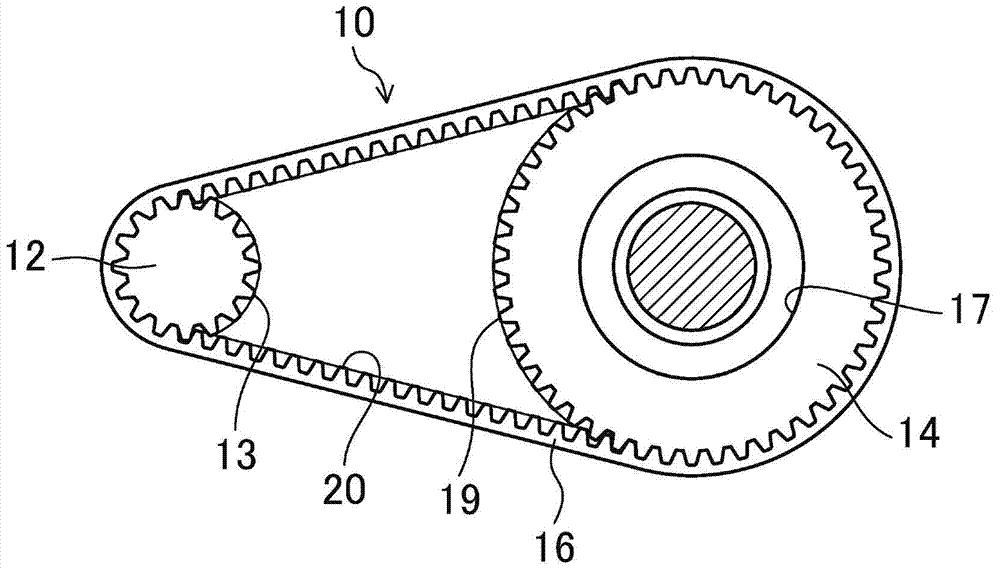

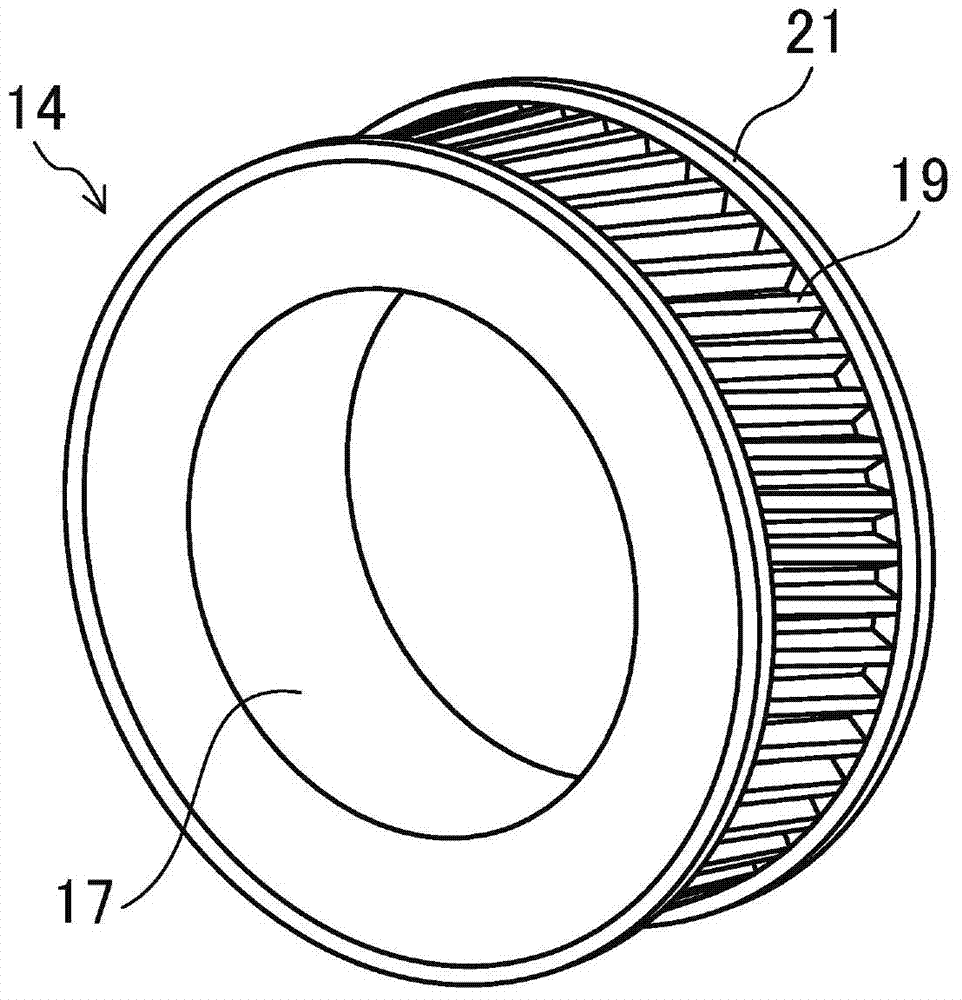

technical field [0001] The technology disclosed in this specification relates to a toothed belt for a power steering device. Background technique [0002] The technique of using a reduction gear having a belt in an electric power steering system for a vehicle is known. For example, Patent Document 1 discloses a belt speed reduction device using a friction belt, that is, a so-called V-belt. In this belt speed reducer, since power is transmitted by friction, it is necessary to apply a large tension to the belt to obtain a sufficient frictional force. For this reason, when the belt speed reducer described in Patent Document 1 is used, the torque at the time of no load increases, and the return of the steering wheel tends to be delayed. [0003] On the other hand, Patent Document 2 discloses a belt speed reduction device using a spur belt (toothed belt). In this kind of belt deceleration device, since the force is transmitted through the meshing of the pulley teeth and the be...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16G1/28B62D5/04F16G1/08F16H7/02

CPCF16G1/28F16G1/10F16H7/023B62D3/02F16H55/14B62D5/0424B62D5/04

Inventor 关口勇次中岛荣二郎

Owner BANDO CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com