Self-pressing pot cover structure

A technology of self-pressing and pot lid, which is applied to pressure cookers and other directions, can solve the problems of high labor intensity and long time required for opening and closing the pot lid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

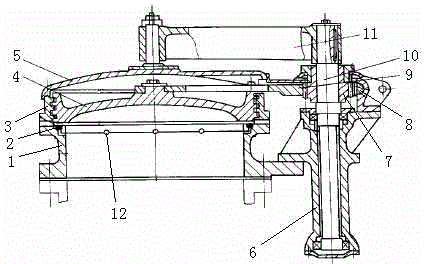

[0013] Such as figure 1 As shown, a self-pressing type pot cover structure includes a pot cover neck 1 and a lower pot cover 4, wherein it includes a vertical shaft seat 6, a hydraulic cylinder, an upper pot cover 5, a cantilever 11, a large nut 3, a sealing expansion ring and The rotary mechanism, in the present embodiment, the sealing expansion ring is a π-shaped sealing expansion ring 2, and the rotary mechanism includes a rack 8, a vertical shaft 10, a driving gear 7 and a sector gear 9, and the lower end of the vertical shaft seat 6 is fixed on the pot body, and the vertical shaft 10 and The vertical shaft base 6 is rotatably connected, and the drive gear 7 is fixedly connected to the vertical shaft 10. The drive gear 7 meshes with the rack 8, and the rack 8 is driven by a hydraulic cylinder. The drive gear 7 also meshes with the sector gear 9, which is far away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com